NCK start-up

10.6 Parameterization of spindle data

CNC Part 1 (NCK, PLC, drive)

166 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

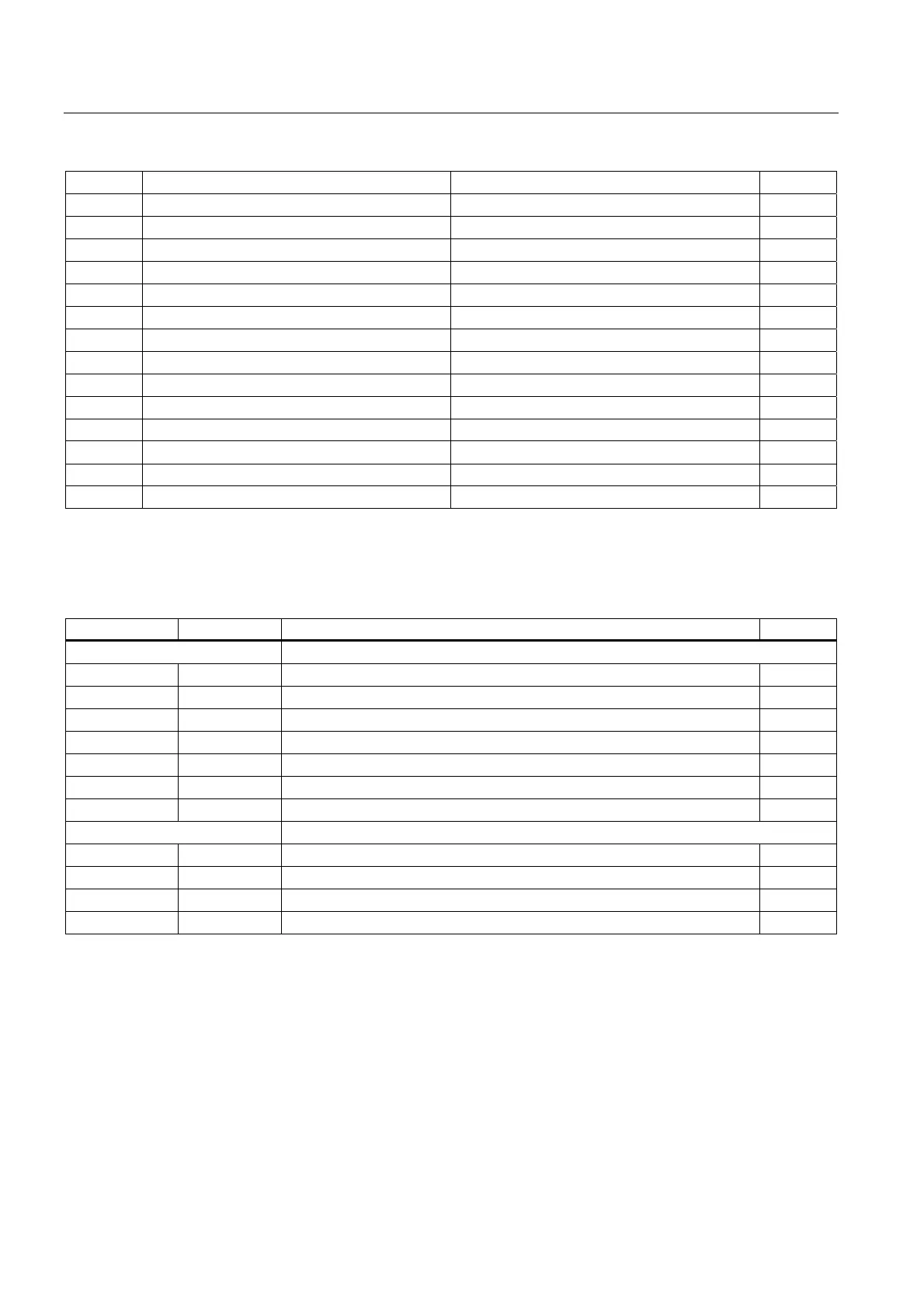

31060 DRIVE_AX_RATIO_NUMERA Numerator load gearbox G2

32010 JOG_VELO_RAPID Rapid traverse in the JOG mode

32020 JOG_VELO JOG axis velocity

35010 GEAR_STEP_CHANGE_ENABLE Gear stage change possible

35020 SPIND_DEFAULT_MODE Basic spindle setting

35030 SPIND_DEFAULT_ACT_MASK Activate initial spindle setting

35040 SPIND_ACTIVE_AFTER_RESET Spindle active after reset

35200 GEAR_STEP_SPEEDCTRL_ACCEL[n] Acceleration in speed control mode

35220 ACCEL_REDUCTION_SPEED_POINT Speed limit for reduced acceleration

35230 ACCEL_REDUCTION_FACTOR Reduced acceleration

35400 SPIND_OSCILL_DES_VELO Oscillation speed

35410 SPIND_OSCILL_ACCEL Acceleration during oscillation

35430 SPIND_OSCILL_START_DIR Starting direction during oscillation

35440 SPIND_OSCILL_TIME_CW Oscillation time for M3 direction

35450 SPIND_OSCILL_TIME_CCW Oscillation time for M4 direction

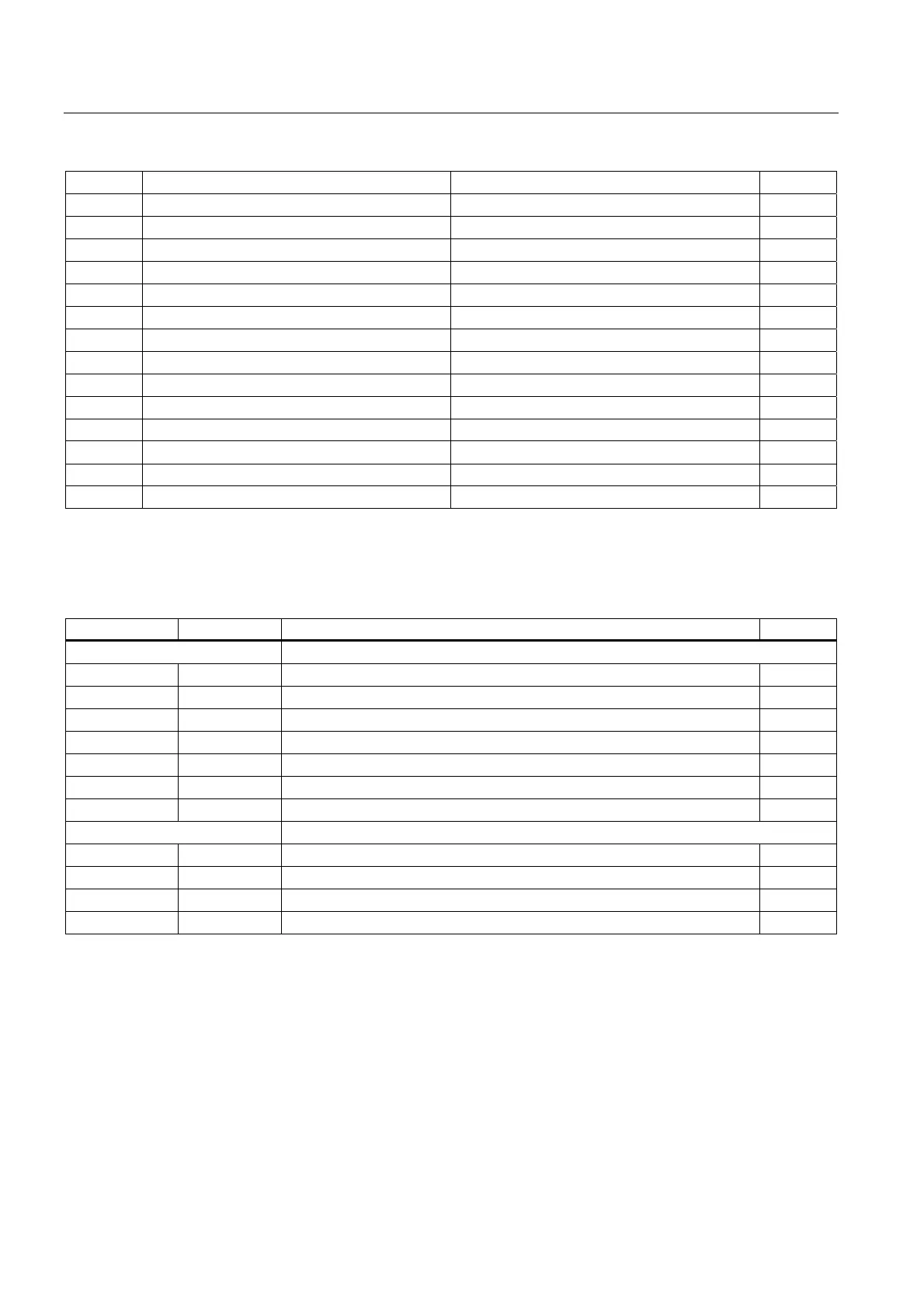

Interface signals

Table 10-28 Speeds and setpoint adjustment for spindle: Interface signals

DB number Bit, byte Name Reference

Axis-specific Signals from PLC to axis/spindle

31, ... 4.6 Traversing keys minus

31, ... 4.7 Traversing keys plus

31, ... 16.2-16.0 Actual gear stage

31, ... 16.3 Gear changed

31, ... 16.6 No speed monitoring when changing the gear

31, ... 18.4 Oscillation via PLC

31, ... 18.5 Reciprocating speed

Axis-specific Signals from axis/spindle to PLC

31, ... 82.2-82.0 Set gear stage

31, ... 82.3 Change gear stage

31, ... 84.7 Active spindle control mode

31, ... 84.6 Active spindle mode oscillation mode

Loading...

Loading...