Fundamentals

15.8 Axis data

CNC Part 1 (NCK, PLC, drive)

294 Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

In the two axis-specific machine data:

• MD30110 CTRLOUT_MODULE_NR[0] (setpoint assignment: logic drive number)

• MD30220 ENC_MODUL_NR[n] (actual value assignment: logic drive number)

the index m for the DRIVE_LOGC_ADRESS of the drive is entered, which represents the

machine axis.

The entered value m refers to the drive whose I/O address is defined under the index n = (m-

1) in MD13050 DRIVE_LOGIC_ADDRESS[n] (see Chapter "Drive Configuration").

NCK Reset

Once the drive configuration and setpoint/actual value assignment have been

parameterized, an NCK reset must be executed to initiate a warm restart of the NC. After the

NC has powered up, the set configuration is effective.

Measuring system switchover

The interface signals

• DB31, ... DBX1.5 (position measuring system 1 selected)

• DB31, ... DBX1.6 (position measuring system 2 selected)

can be used to switch from the PLC between the two position measuring systems of a

machine axis.

Literature

Function Manual Basic Functions; Diverse Interface Signals

Machine data

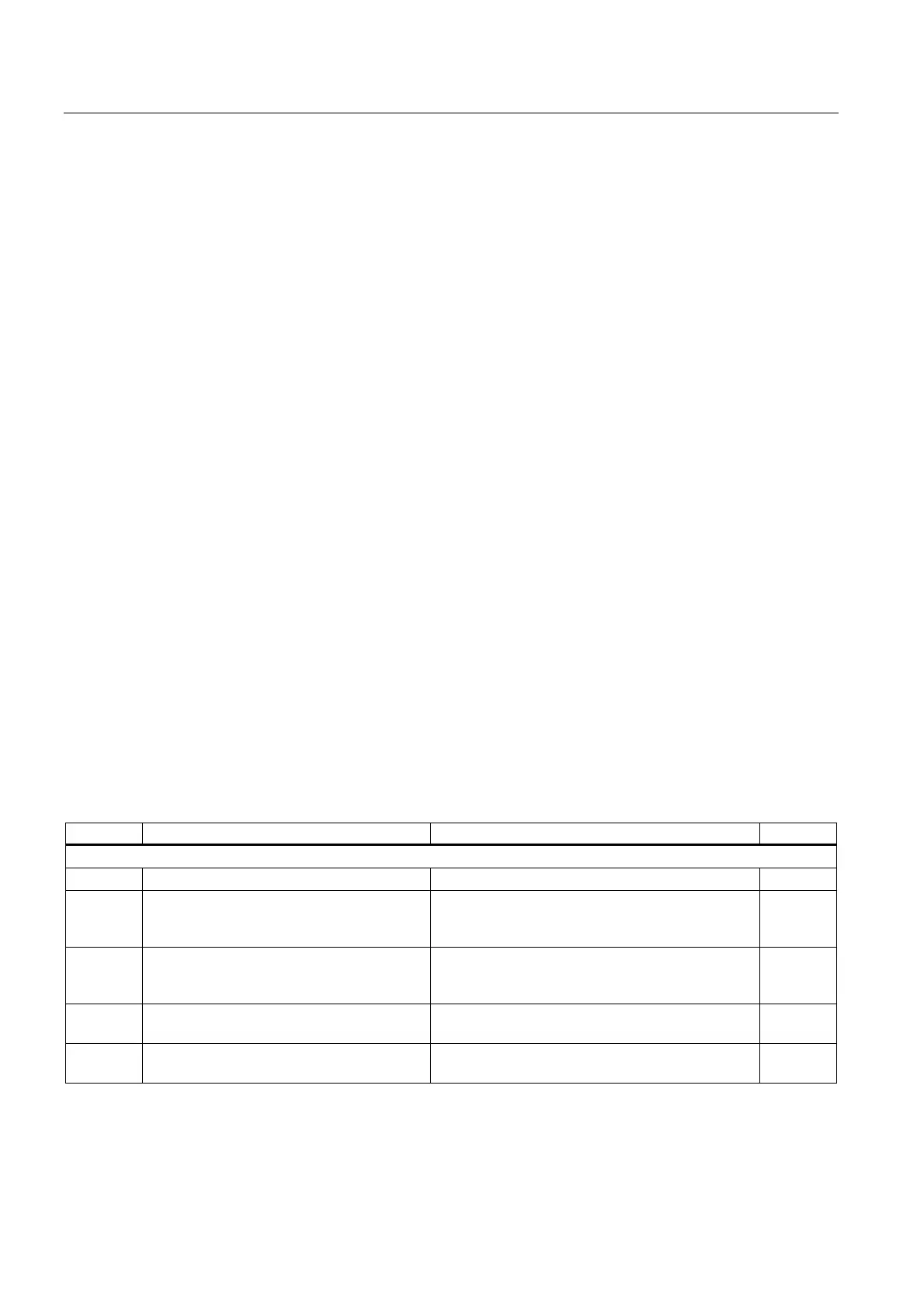

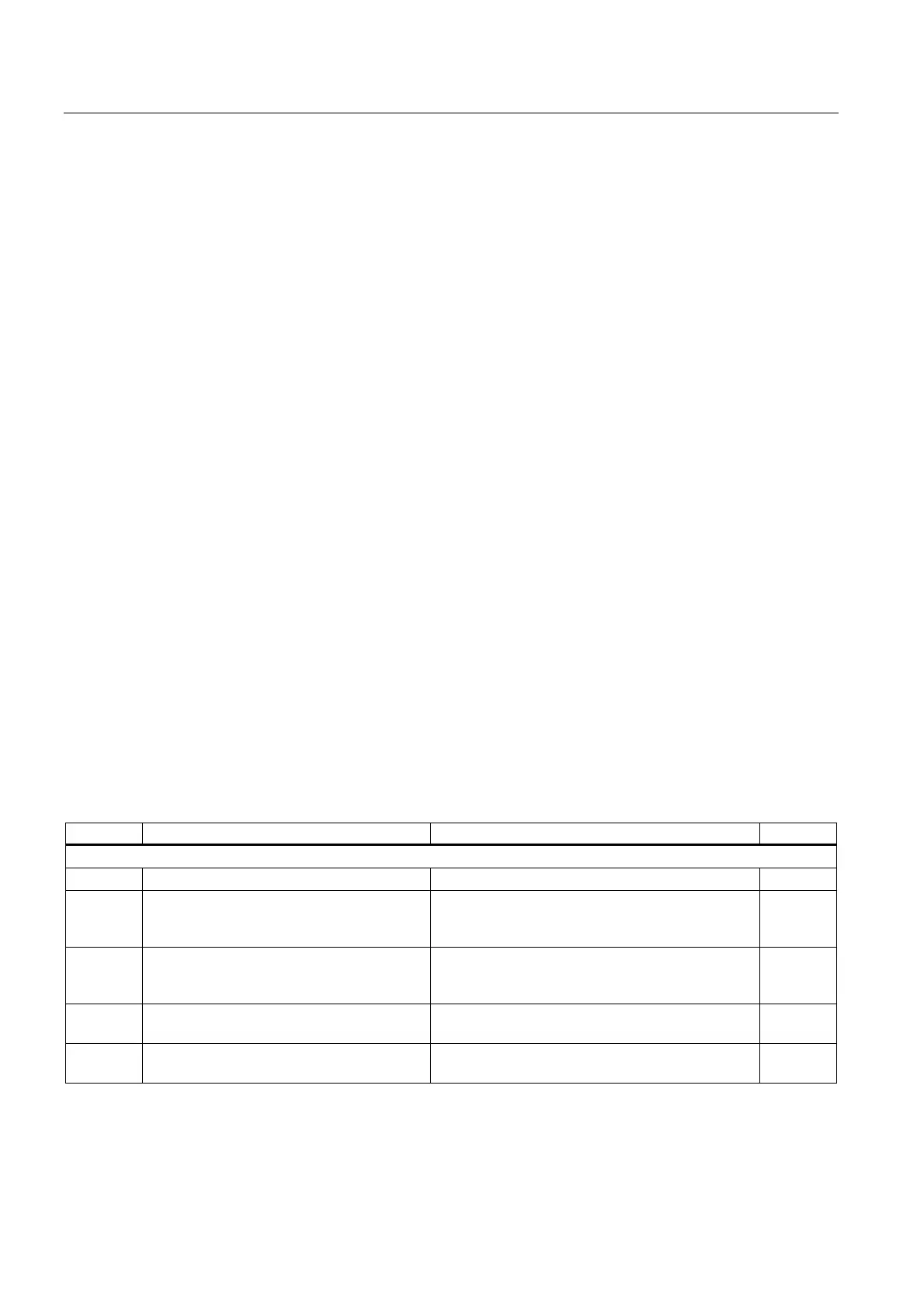

Table 15-10 Setpoint/actual value channels: Machine data

Number Name of identifier Name / remarks Reference

Axisspecific ($MA_ ... )

30110 CTRLOUT_MODULE_NR Setpoint assignment: Logical drive number

30130 CTRLOUT_TYPE Output of setpoint value

0 = Simulation

1 = Output of speed setpoint

30200 NUM_ENCS Number of measuring channels

1 = One position measuring system present

2 = Two position measuring systems present

30220 ENC_MODULE_NR[0] Actual value assignment: Logic drive number for

position measuring system 1

30220 ENC_MODULE_NR[1] Actual value assignment: Logic drive number for

position measuring system 2

Loading...

Loading...