Fundamentals

15.9 Spindle data

CNC Part 1 (NCK, PLC, drive)

Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

301

MD31050 $MA_DRIVE_AX_RATIO_DENOM (Measuring gear denominator)

MD31060 $MA_DRIVE_AX_RATIO_NUMERA (Numerator load gear unit)

MD32200 $MA_POSCTRL_GAIN (Servo gain factor (Kv))

MD32452 $MA_BACKLASH_FACTOR (Weighting factor for backlash)

MD32610 $MA_VELO_FFW_WEIGHT (Weighting factor for feedforward control)

MD32800 $MA_EQUIV_CURRCTRL_TIME (Equivalent time constant current control circuit

for feedforward control)

MD32810 $MA_EQUIV_SPEEDCTRL_TIME (Equivalent time constant speed control loop for

feedforward control)

MD32910 $MA_DYN_MATCH_TIME (Time constant for dynamic matching)

MD36012 $MA_STOP_LIMIT_FACTOR (Factor for exact stop coarse/fine and zero speed

control)

MD36200 $MA_AX_VELO_LIMIT (Threshold value for velocity monitoring)

• The dynamic limits of the axis stored in the machine data are applicable in axis operation.

• The axis switches to the current feedforward control mode as designated by the MD and

the commands FFWON and FFWOF.

Other notes on the servo parameter set:

References:

/FB1/Function Manual, Basic Functions; Velocities, Setpoint/Actual-Value System,

Closed-Loop Control (G2)

• When using resolution changes in (analog) drive actuators, the following NC program

steps are required:

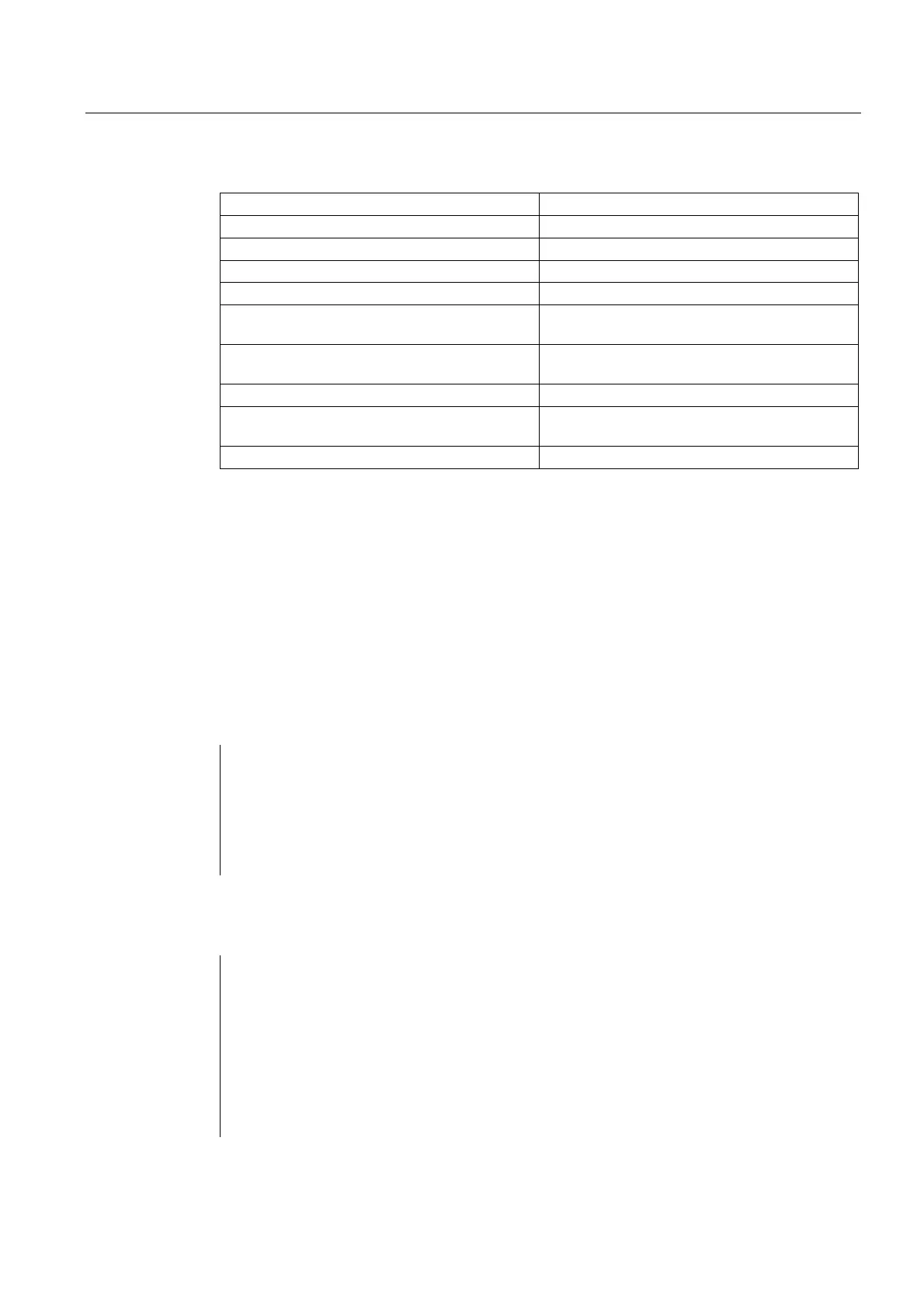

Table 15-12 Change over to axis mode:

SPOS=...

M5

Closed-loop controller enable off (by PLC)

→ Output to PLC

M70

Switch actuator (by PLC on account of M70)

Closed-loop controller enable on (by PLC)

C=...

NC travels with axis parameter set

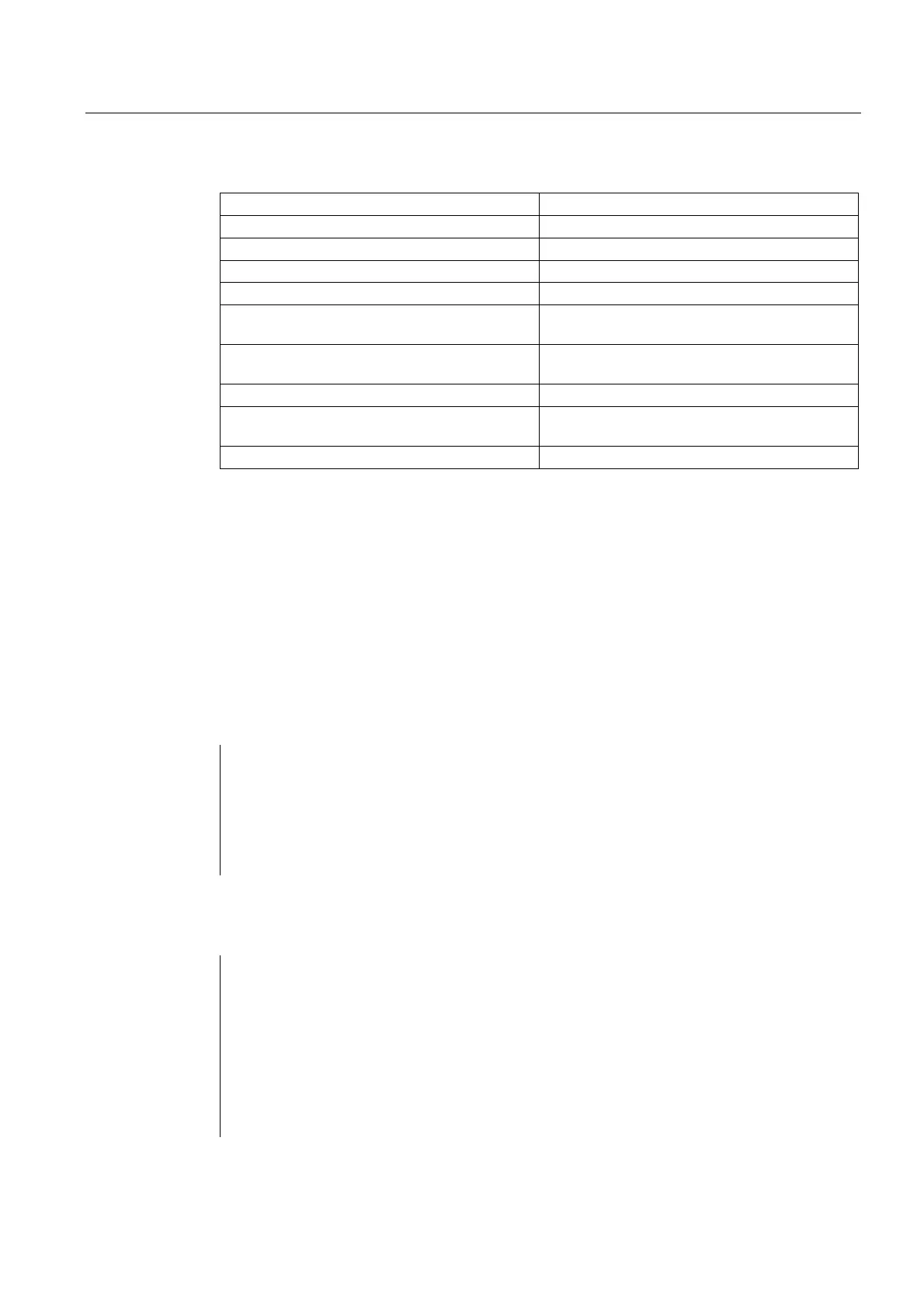

Table 15-13 Switch back to spindle mode

C=...

M71

→ Output to PLC

Closed-loop controller enable off (by PLC)

Switch actuator (by PLC)

Switched to spindle parameter set (1-5) internally in the NC,

controller enable on (by PLC)

M3/4/5

or

SPOS=...

NC travels with spindle parameter set

Loading...

Loading...