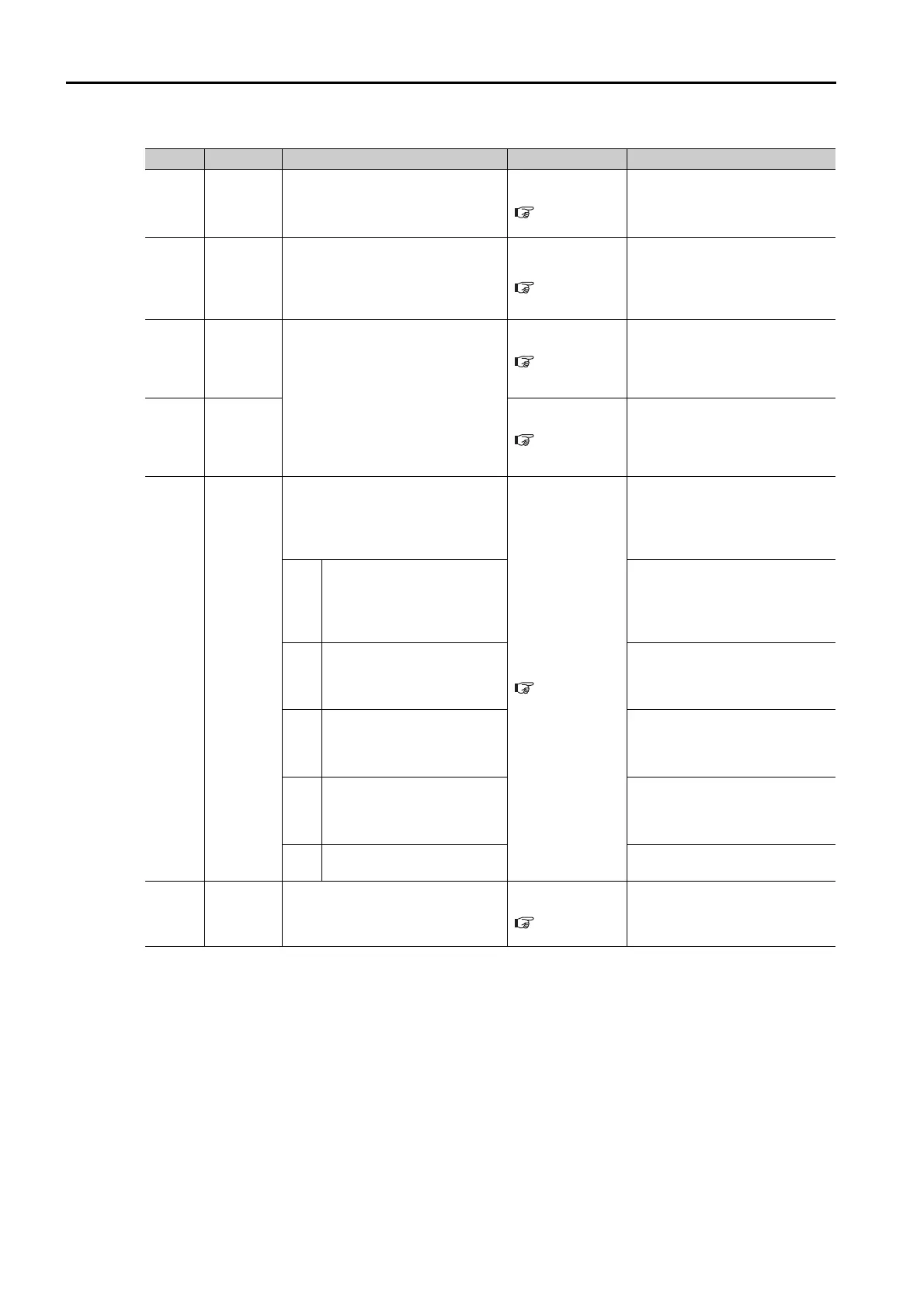

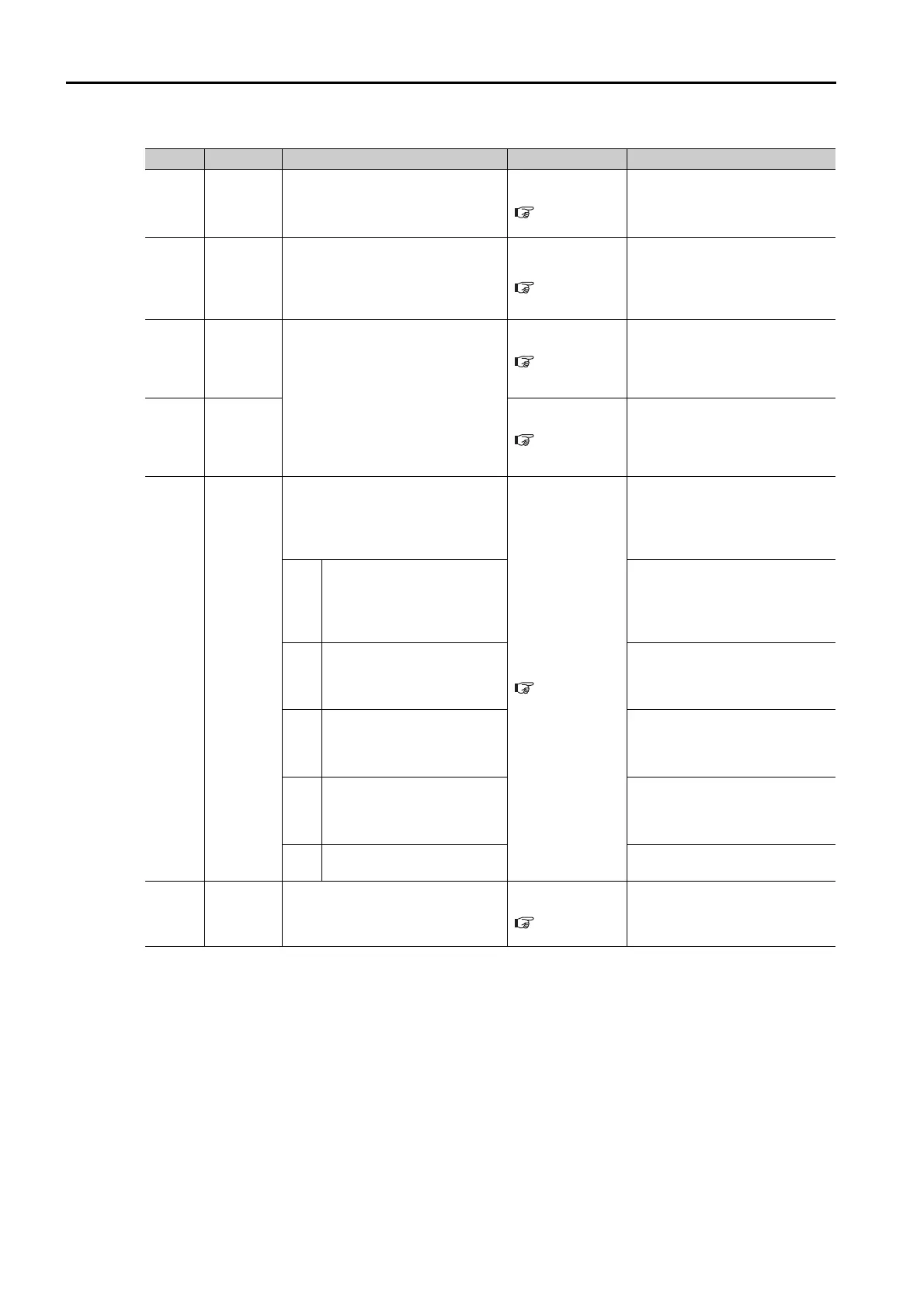

7.3 Program Table Operation

7.3.5 Settings in the Program Table

7-20

PSPD

Pressing

speed

Specifies the speed for pressing

operation.

This value does not need to be set

for positioning operation.

Refer to the fol-

lowing section.

PSPD on

page 7-27

–

INPOS

Position-

ing com-

pleted

width

For positioning operation, speci-

fies the positioning completed

width (INPOSITION width).

For pressing operation, specifies

the pressing travel distance.

Refer to the fol-

lowing section.

INPOS on

page 7-27

–

AREA1

Area

edge 1

The /PAREA signal turns ON if the

current value of the motor is within

the area defined by two positions

(called AREA1 and AREA2).

The /PAREA signal will remain OFF

if both AREA1 and AREA2 are set

to 0.

Refer to the fol-

lowing section.

AREA1 and

AREA2 on

page 7-28

–

AREA2

Area

edge 2

Refer to the fol-

lowing section.

AREA1 and

AREA2 on

page 7-28

–

EVENT

End con-

dition

Specifies the condition to use to

determine when the program step

is completed. When the condition

is met, execution jumps to the

program step specified by NEXT.

Refer to the fol-

lowing section.

EVENT on

page 7-28

–

ITn

Execution waits for n milli-

seconds after the

/INPOSITION (Positioning

Completion Output) signal

turns ON (closes).

–

NTn

Execution waits for n milli-

seconds after the /NEAR

(Near Output) signal turns

ON (closes).

–

BTn

Execution waits for n milli-

seconds after the /BUSY

(Busy Output) signal turns

OFF (opens).

–

Tn

The NEXT program step

starts after the specified

time elapses after starting

the current program step.

–

:

The condition from the pre-

vious program step is used.

–

NEXT

Next pro-

gram step

Specify the program step to exe-

cute after completion of the cur-

rent program step.

Refer to the fol-

lowing section.

NEXT on

page 7-29

–

Continued from previous page.

Item Name Description Setting Method Remarks

Loading...

Loading...