STARTUP

Axio Scope.A1 Mounting the Standard Components Carl Zeiss

M60-2-0007 e 05/08 37

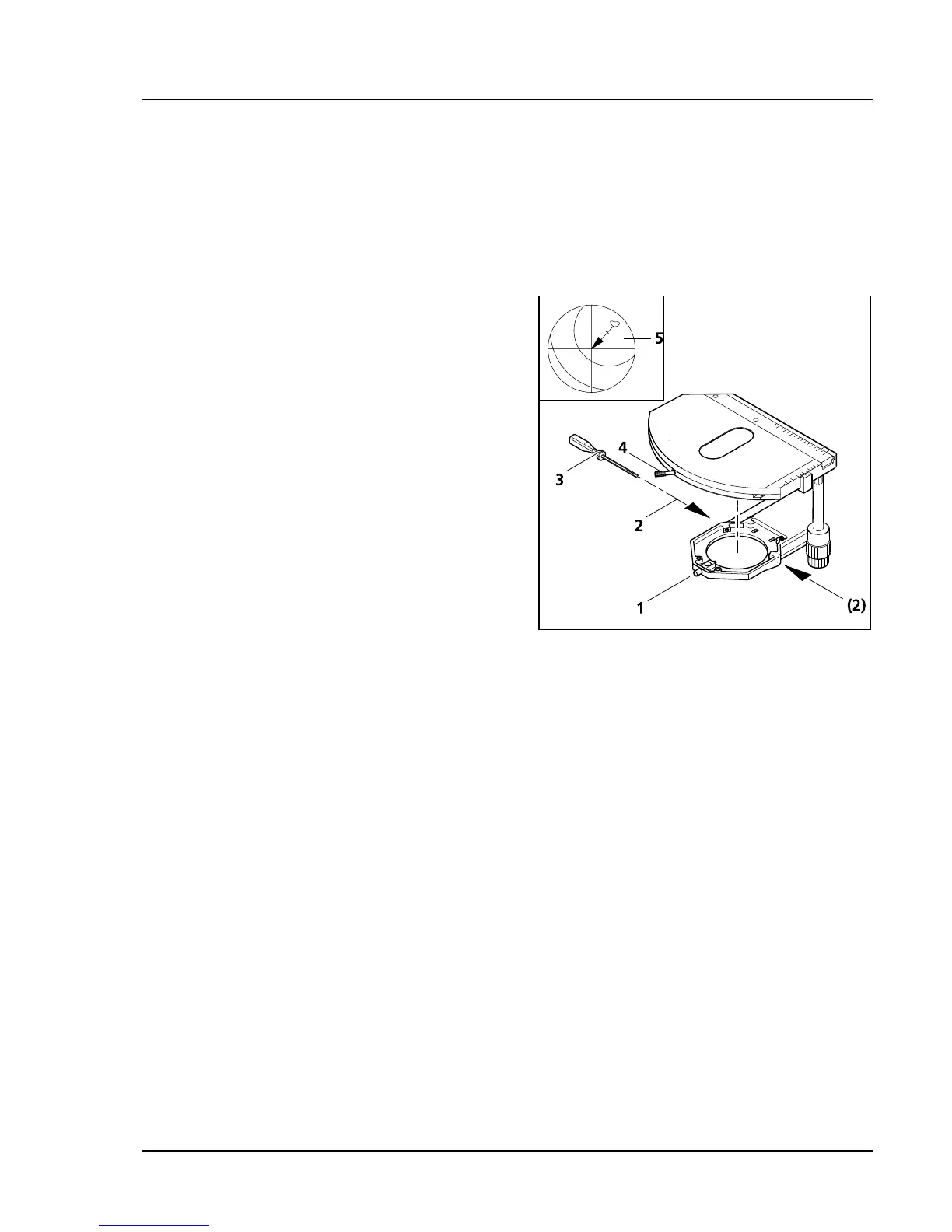

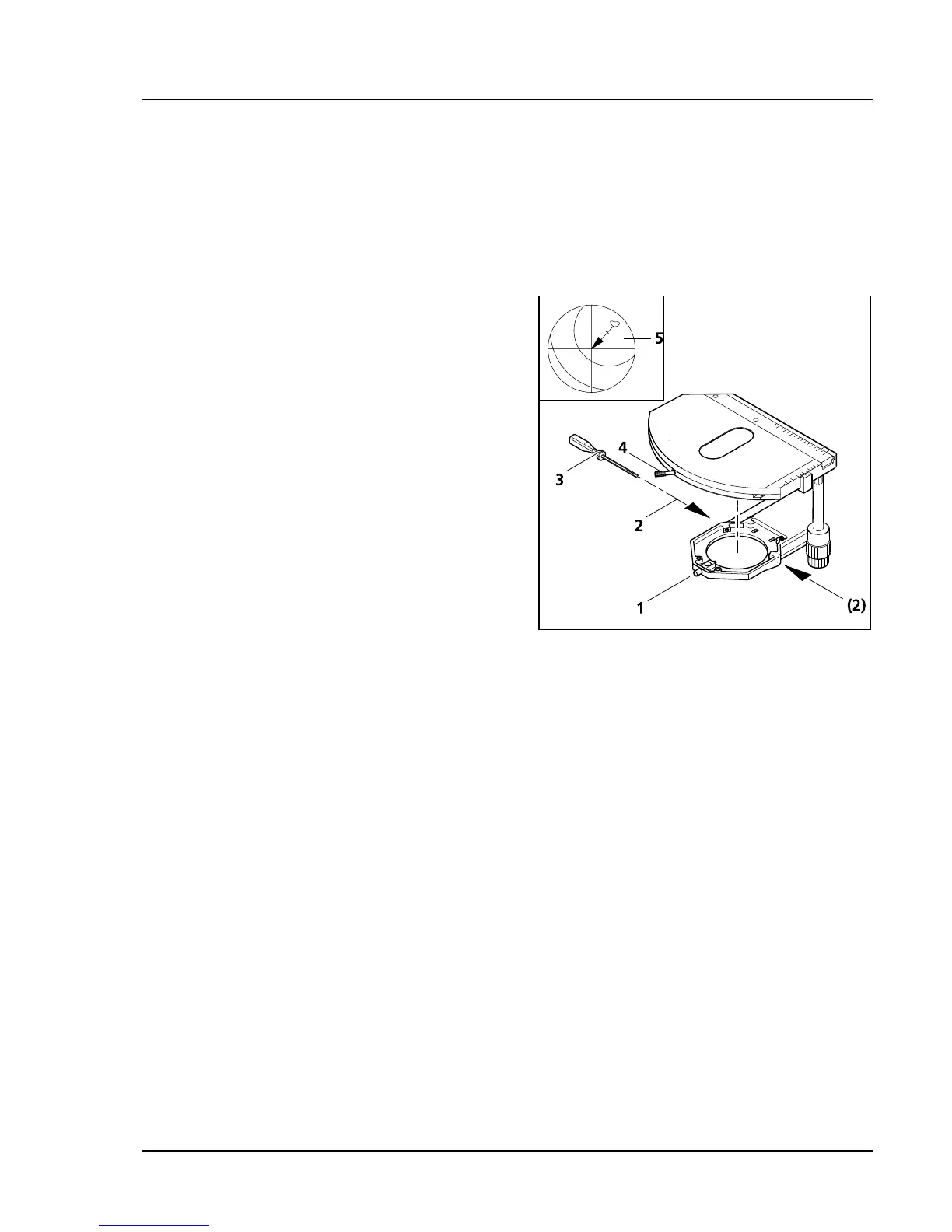

b) How to mount the stage

• Loosen the screw caps (

338H338HFig. 3-11/2) of the spring box with approx. 3 turns.

• Put the stage with the dovetail ring notch onto the spring pin (

339H339HFig. 3-11/1).

• Press the stage forward against the spring pin and lower its back into the stage carrier (

340H340HFig. 3-11/3).

• Tighten the screw caps (

341H341HFig. 3-11/2).

c) How to center the stage

When using objectives with a high magnification,

only one chosen objective can be centered exactly

at a time.

All stages are delivered precentered, i.e. when the

stage is turned, the detail of the object in the focus

remains in the center of the image. If the detail

shifts out of the center when the stage is turned

(

342H342HFig. 3-12/5), then it becomes necessary to recenter

the stage.

• Loosen the clamping screws of the stage (

343H343HFig.

3-12/4) and the screw caps of the stage carriers

(

344H344HFig. 3-12/1).

• Determine the maximal shift of the object (

345H345HFig.

3-12/5, arrow point) to the cross line in the

eyepiece by turning the stage.

• Shift the object detail towards the center of the

cross line by turning the two centering screws

on the stage carrier (

346H346HFig. 3-12/2) each with an

hexagon head screwdriver SW 1.5 (

347H347HFig. 3-12/3)

half the length of the arrow. Repeat the

procedure if the object detail shifts out of the

center again when turning the stage.

• After finishing the centering procedure tighten the screw caps (

348H348HFig. 3-12/1) again.

The stage can be turned by 240° within a shifting range of y ≤ 27 mm. No turning of the stage is possible

outside of this range.

(3) Adjusting the drive length on the ergonomics

An axial shift of the gear knobs by a maximum of 15 mm can enhance the drive length of the X and Y

shift on the mechanical stages with ergonomic drive.

Fig. 3-12 Centering the rotatable mechanical

stage

Loading...

Loading...