STARTUP

Axio Scope.A1 Mounting the Standard Components Carl Zeiss

M60-2-0007 e 05/08 39

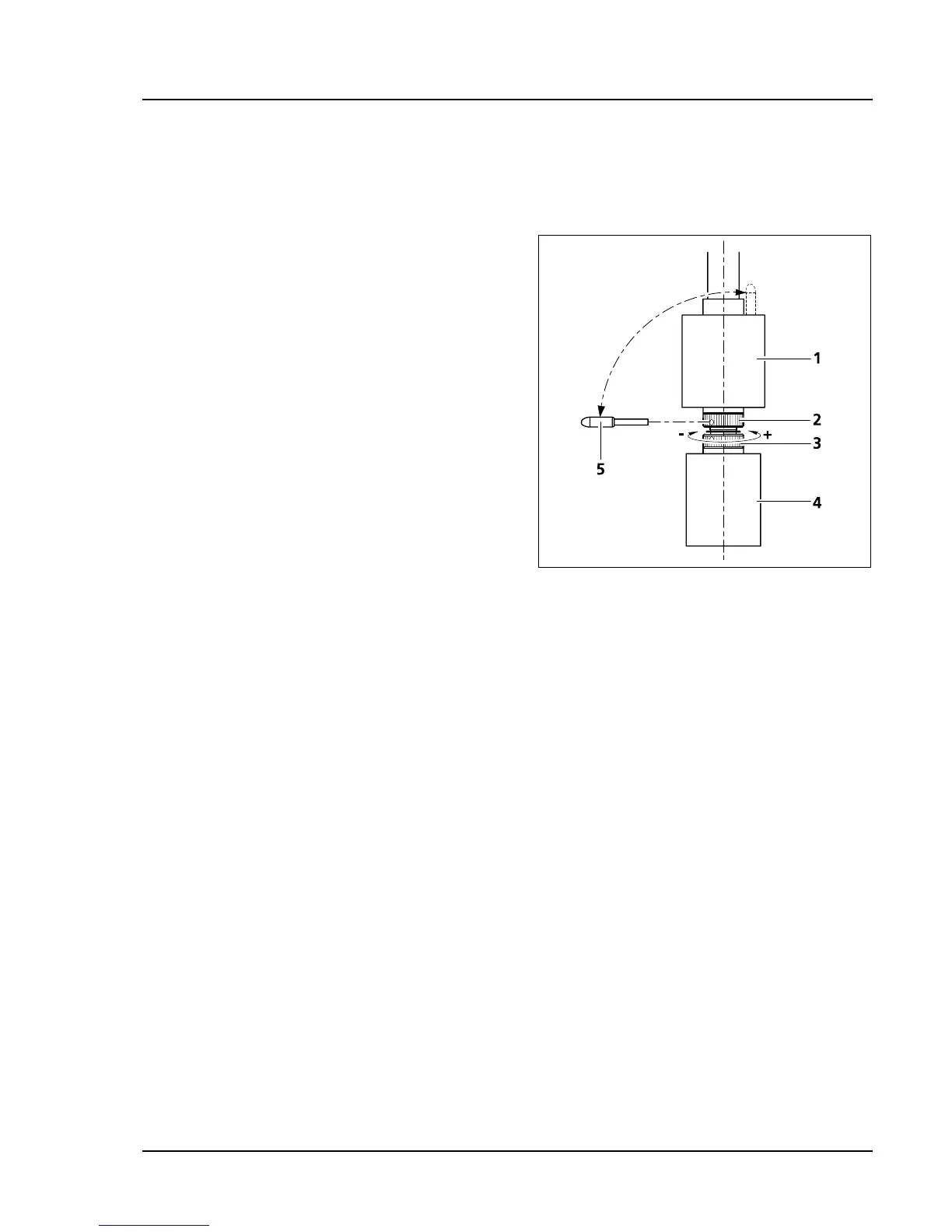

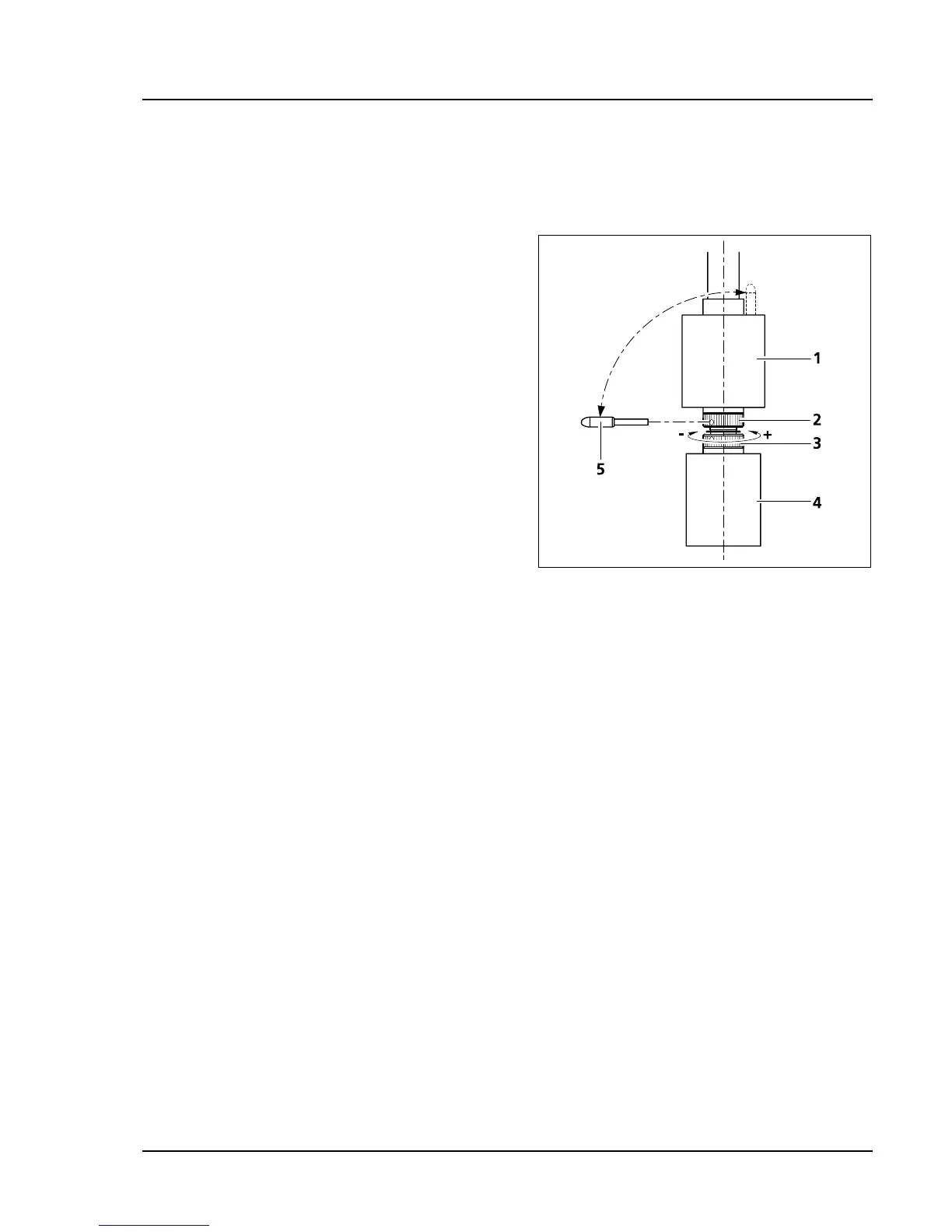

3.1.9 Mechanical Stages with Friction Adjustment

Drive length and friction for the X- and Y-adjustment can be adjusted individually on the standard

mechanical stage (432035-9000-000) and the mechanical stage 432035-9070-000.

(1) Adjusting the drive length on the stage

drive

The drive length of the X- and Y-drive can be

adjusted by an axial shift of the gear knob

(

360H360HFig. 3-14/4 and 1) within a range of approx.

15 mm.

(2) Adjusting the frictional momentum of the

gear knobs for the X-/Y-adjustment of the

mechanical stage

The friction momentum of the gear knobs is

factory-adjusted to a mid degree which can be

changed as follows if necessary:

a) X-drive

• Slide the gear knob for the X-adjustment (

361H361HFig.

3-14/4) all the way down.

• Take the enclosed adjustment pin (

362H362HFig. 3-14/5)

out of the gear knob for the Y-adjustment (

363H363HFig.

3-14/1) and stick it into one of the holes on the

lower hole nut (

364H364HFig. 3-14/3).

• Hold the gear knob for the X- adjustment (

365H365HFig. 3-14/4) and turn the hole nut with the adjustment pin

clockwise (smaller friction momentum: –) or counter clockwise (larger friction momentum: +) until you

reach the desired friction degree (see

366H366HFig. 3-14).

• The adjustment should not be more than one rotation.

b) Y-drive

• Slide the gear knob for the Y-adjustment (

367H367HFig. 3-14/1) all the way up.

• Stick the enclosed adjustment pin (

368H368HFig. 3-14/5) into the hole on the upper hole nut (369H369HFig. 3-14/2).

• Hold the gear knob for the Y-adjustment (

370H370HFig. 3-14/1) and turn the hole nut with the adjustment pin

clockwise (smaller friction momentum: –) or counter clockwise (larger friction momentum: +) until you

reach the desired friction degree.

• The adjustment should not be more than one rotation.

• Replace the adjustment pin in the gear knob for the Y-adjustment (

371H371HFig. 3-14/1).

Fig. 3-14 Adjusting the frictional momentum

Loading...

Loading...