Valve Seat

Servicing

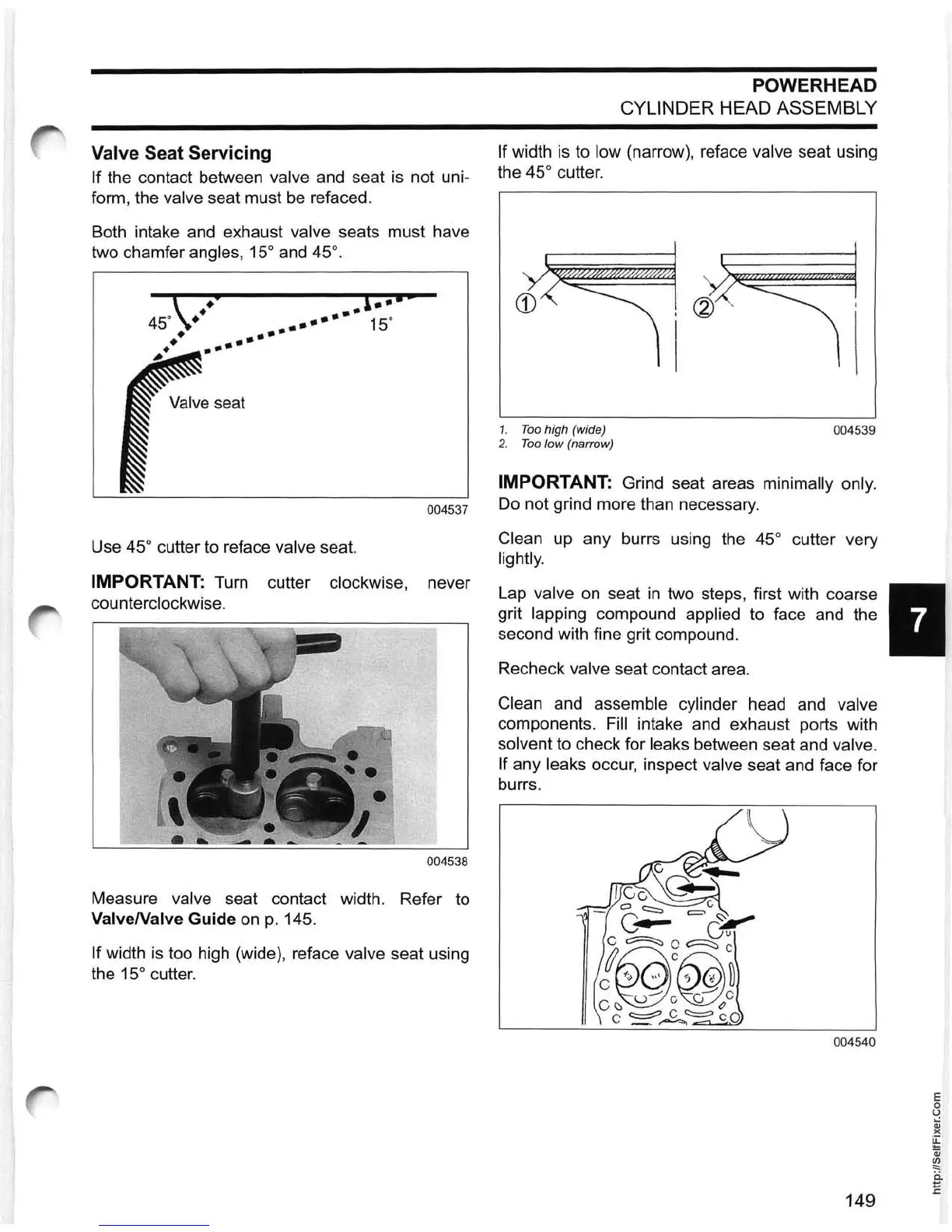

If the contact between valve and seat

is

not uni-

form, the

valve seat must

be

refaced.

Both intake and exhaust

valve seats must have

two chamfer

angles,

15°

and 45

°.

\ •• *

45

° •

•••

• •••

•••

1

.i

D

• •

••••

15"

•••

Use 45° cutter

to

reface valve seat.

004537

IMPORTANT: Turn cutter clockwise, never

cou

nterclockwise.

004538

Measure valve seat contact width. Refer to

ValveNalve Guide

on

p. 145.

If width

is

too high (wide), reface valve seat using

the 15° cutter.

POWERHEAD

CYLINDER HEAD ASSEMBLY

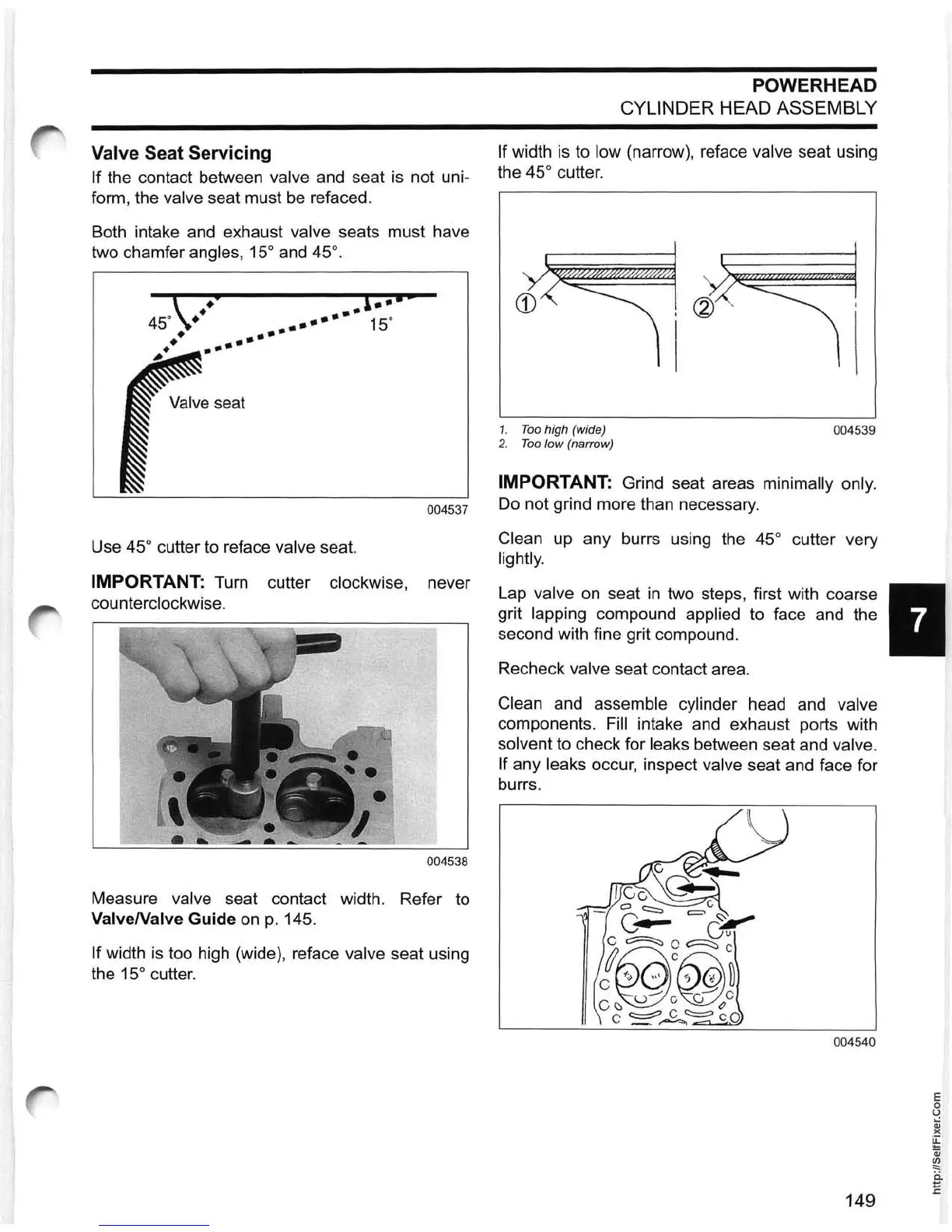

If width

is

to low (narrow), reface valve seat using

the 45° cutter.

1.

Too

high (wide)

004539

2.

Too

low (narrow)

IMPORTANT: Grind seat areas minimally only.

Do

not grind more than necessary.

Clean up any burrs using the 45° cutter very

lightly.

Lap valve

on

seat

in

two steps, first with coarse 7

grit lapping compound applied

to

face and the

second with fine grit compound.

Recheck

valve seat contact area.

Clean and assemble cylinder head and valve

components. Fill intake and exhaust ports with

solvent to check for leaks between seat and valve.

If

any leaks occur, inspect valve seat and face for

burrs.

004540

149

E

o

U

Qj

)(

~

Qj

~

ii

E

Loading...

Loading...