POWERHEAD

CYLINDER/CRANKCASE/PISTON ASSEMBLY

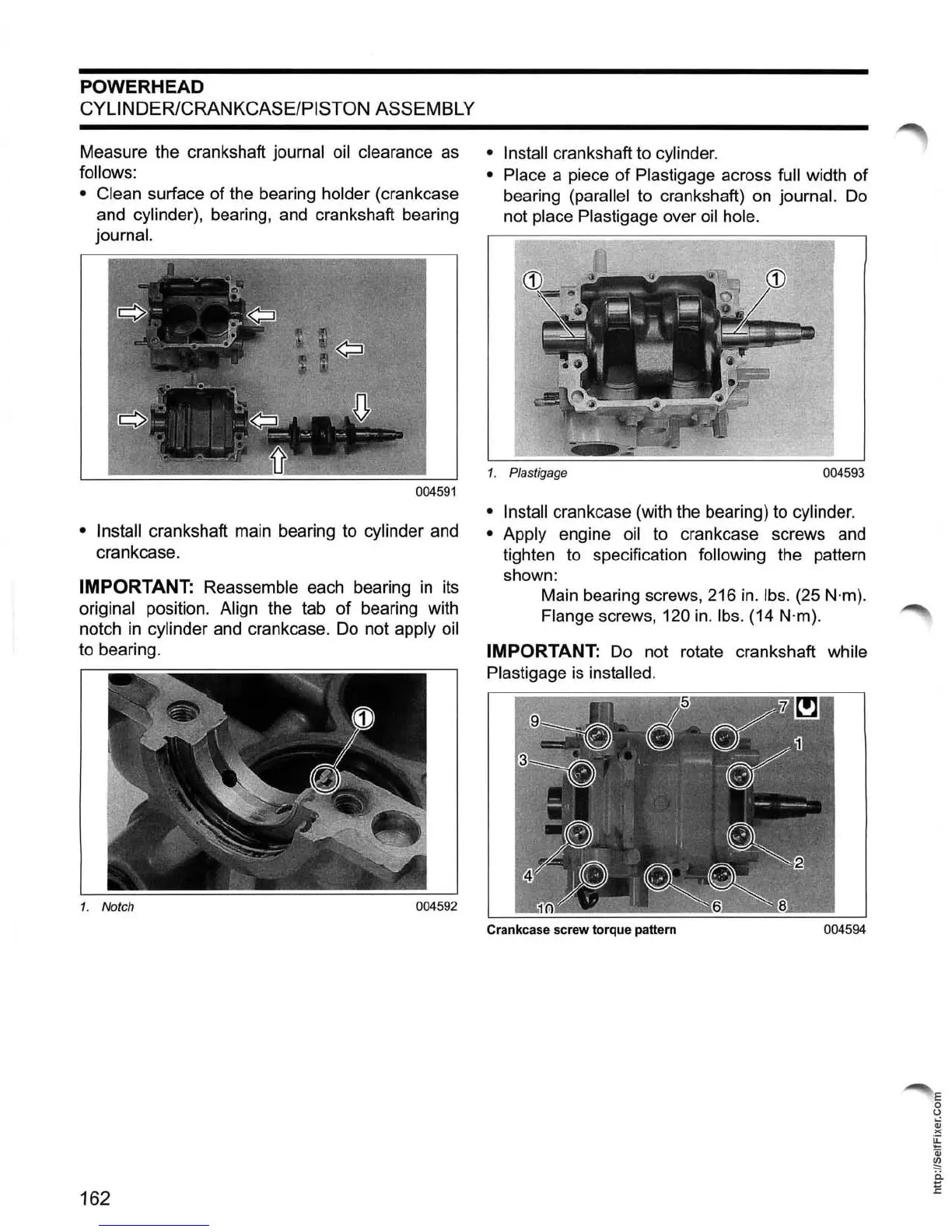

Measure the crankshaft journal oil clearance

as

follows:

• Clean

surface of the bearing holder (crankcase

and cylinder), bearing,

and

crankshaft bearing

journal.

004591

• Install crankshaft

main

bearing to cylinder

and

crankcase.

IMPORTANT: Reassemble each bearing

in

its

original position. Align the tab of bearing with

notch

in

cylinder

and

crankcase.

Do

not apply

oil

to

bearing.

1. Notch

004592

162

• Install crankshaft

to

cylinder.

• Place

a piece of Plastigage across full width of

bearing (parallel

to

crankshaft)

on

journal.

Do

not place Plastigage over oil hole.

1.

Pla

stigage 004593

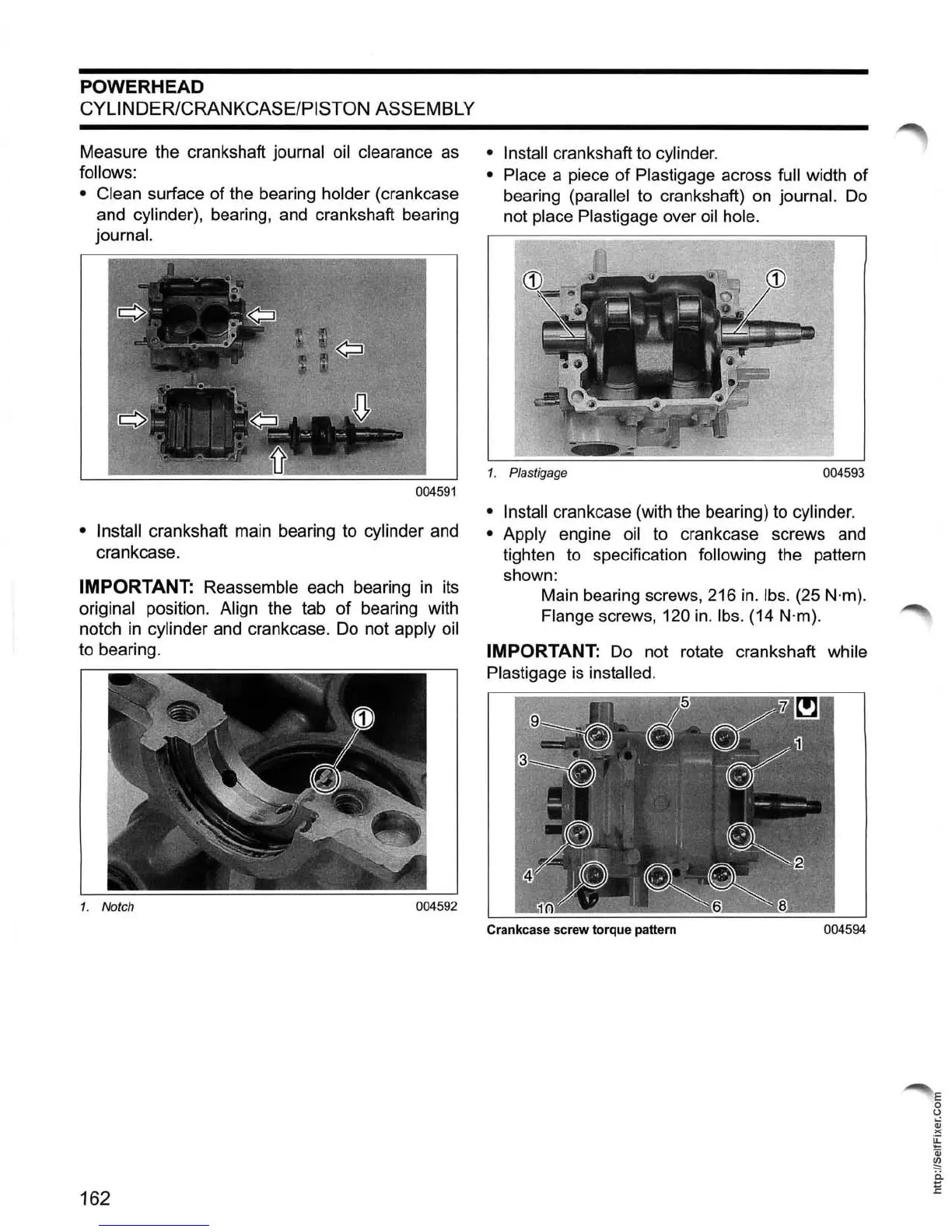

• Install crankcase (with the bearing) to cylinder.

• Apply

engine oil

to

crankcase screws

and

tighten

to

specification following the pattern

shown:

Main bearing screws, 216

in

.

Ibs.

(25 N·m).

Flange

screws,

120

in.

Ibs.

(14 N·m).

IMPORTANT:

Do

not rotate crankshaft while

Plastigage

is

installed.

Crankcase screw torque pattern 004594

Loading...

Loading...