Appendix C Gas Valve

C-26

Safety Valve Max. Oper ating

Pressure

MOP = 5 PSI (360 mbar)

Regulator Oper ating P ressure

Ratings

S22/S82: p

in

= 6 - 147 in. W.C.

S302: p

in

= 14 - 147 in. W.C.

S02: p

in

= 4 - 41 in. W.C.

N: p

in

= 4 - 41 in. W.C.

Regulator Outlet P ressure R anges

S22: p

out

= 1.6 - 8 in. W.C.

S82: p

out

= 2 - 32 in. W.C.

S302: p

out

= 12- 122 in. W.C.

S02: p

out

= 0 ± 0.8 in. W.C.

N: p

out

= 0 ± 0.8 in. W.C.

Ambient Temperature (CSA)

-40 °F ... +140 °F

(-40 °C … +60 °C)

Ambient Temperature (UL)

+5 °F ... +140 °F

(-15 °C … +60 °C)

Gases

Dry, natural gas, propane, butane;

other noncorrosive gases. A “dry” gas

has a dew point lower than +15 °F and

its relative humidity is less than 60 %.

Materials in contact with Gas

Housing: Aluminium, Steel, free of

nonferrous metals. Sealings on valve

seats: NBR-based rubber.

Electrical Ratings

110 - 120 VAC / 50 - 60 Hz;

24 VAC / 50 - 60 Hz; 12 VDC, 24 VDC

Operating time

100 % duty cycle

Cycle Rate

Filter

installed in the housing upstream V1

50 micron

of Valve V1 and V2

Closing Time (Valve 1 & Valve 2)

< 1 s

Opening Time

(Valve 1 & Valve 2)

< 1 s

MBC-

[PSI]

[V] [A]

[Hz ] [VA ]

Gas

°F

0

-40

+150

Electrical Connection

DIN-connector with 1/2” NPT conduit

Order separately for CSA Versions

Power Consumption with all coils

energized

see table below

NEMA

Enclosure Rating

NEMA Type 12 / IP54

Vent Li miting De vice and Vent Li ne

Connection

The MBC has an internal, factory

installed vent limiter re ANSI Z21.18/

CSA 6.3. Venting required unless

otherwise accepted by the authority

having jurisdiction.

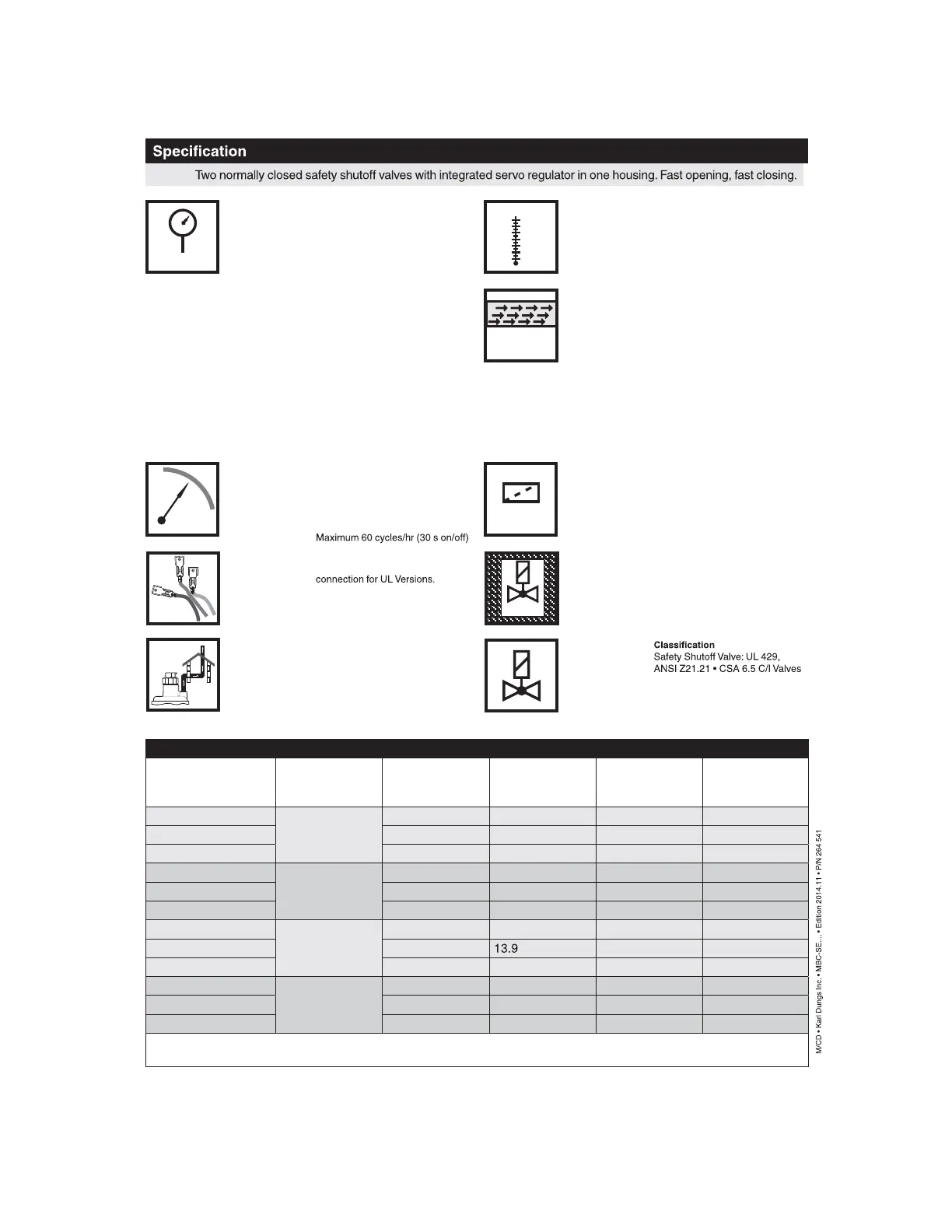

Power Consumption Table

Valve Body Size Rated voltage Inrush P

max.

[VA] for t = 3 s

Inrush current

peak (A)

Holding P

max.

[VA] Operation

Recommended

power of supply

transformer ( VA)

MBC 1000

12 VDC

140 20.1 16 DC battery

MBC 2500 160 20.1 20 DC battery

MBC 4000 ––––

MBC 1000

24 VDC

130 13.4 16 DC battery

MBC 2500 160 13.4 20 DC battery

MBC 4000 200 2.8 30 DC battery

MBC 1000

24 VAC*

120 14.7 20 250

MBC 2500 160

20 300

MBC 4000 ––––

MBC 1000

120 VAC*

120 3.1 16 250

MBC 2500 180 3.0 20 300

MBC 4000 250 2.4 25 300

*Power supply should compensate for the inrush current, and wire gauge should be considered. In order to absorb voltage

spikes during inrush, an electrolytic capacitor (4700 μF) between MBC and transformer is recommended.

Loading...

Loading...