Section 1 — Introduction

Part No. 750-363 1-3

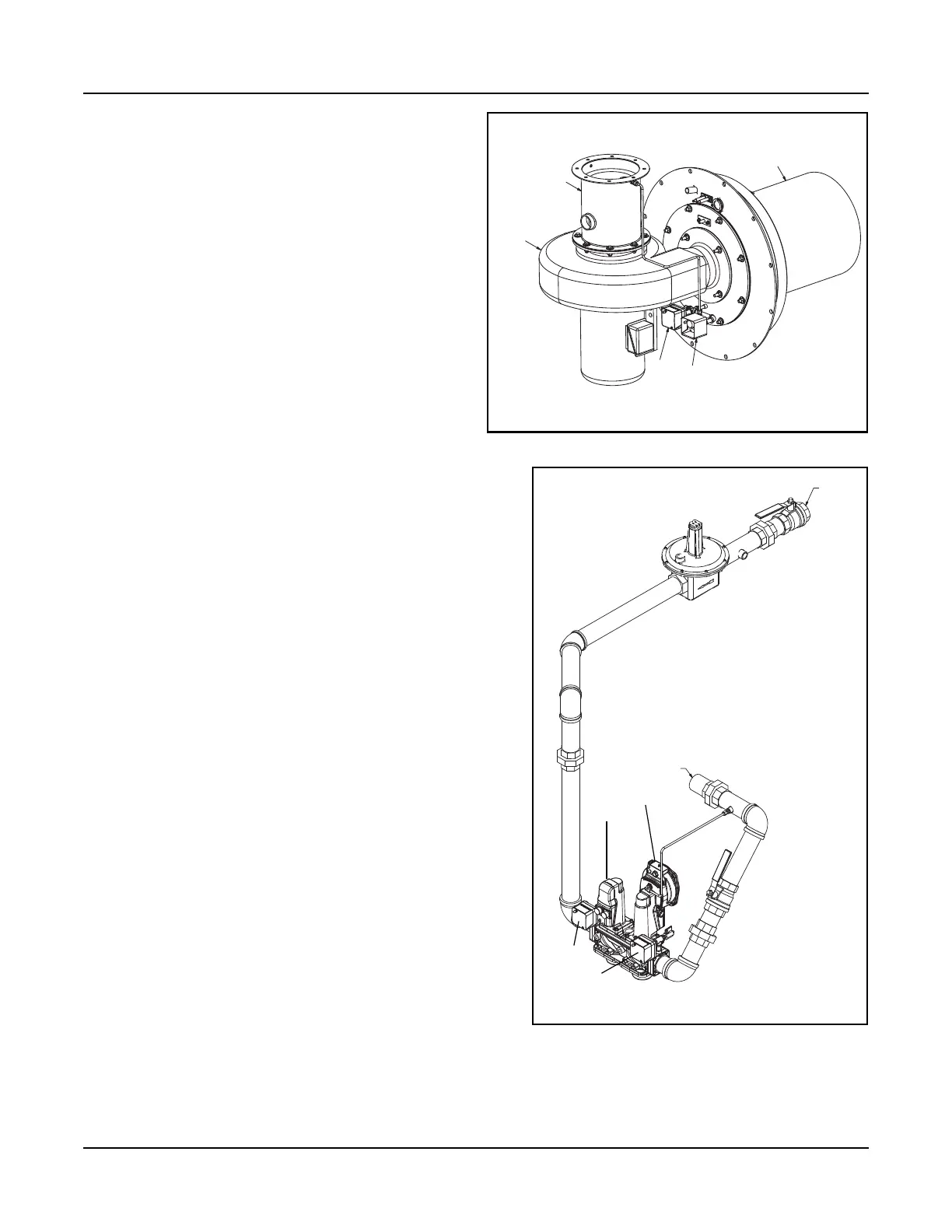

1.2.2. The Burner

The burner utilizes a premix venturi, self-regulating

fuel train, variable speed blower modulation, and

Fecralloy metal fiber burner head.

Modulating combustion air fan provides 5:1

turndown.

Combustion canister of the burner is constructed of a

Fecralloy-metal fiber for solid body radiation of the

burner flame, which provides low emissions.

At maximum firing rate, the sound level of the burner

is less than 85 dBA, measured in front of the boiler at

a distance of 3 feet.

Room air for combustion is standard (combustion air

filter provided).

A direct vent combustion air adapter kit is available.

Refer to Installation and Parts sections in this manual

for options and details.

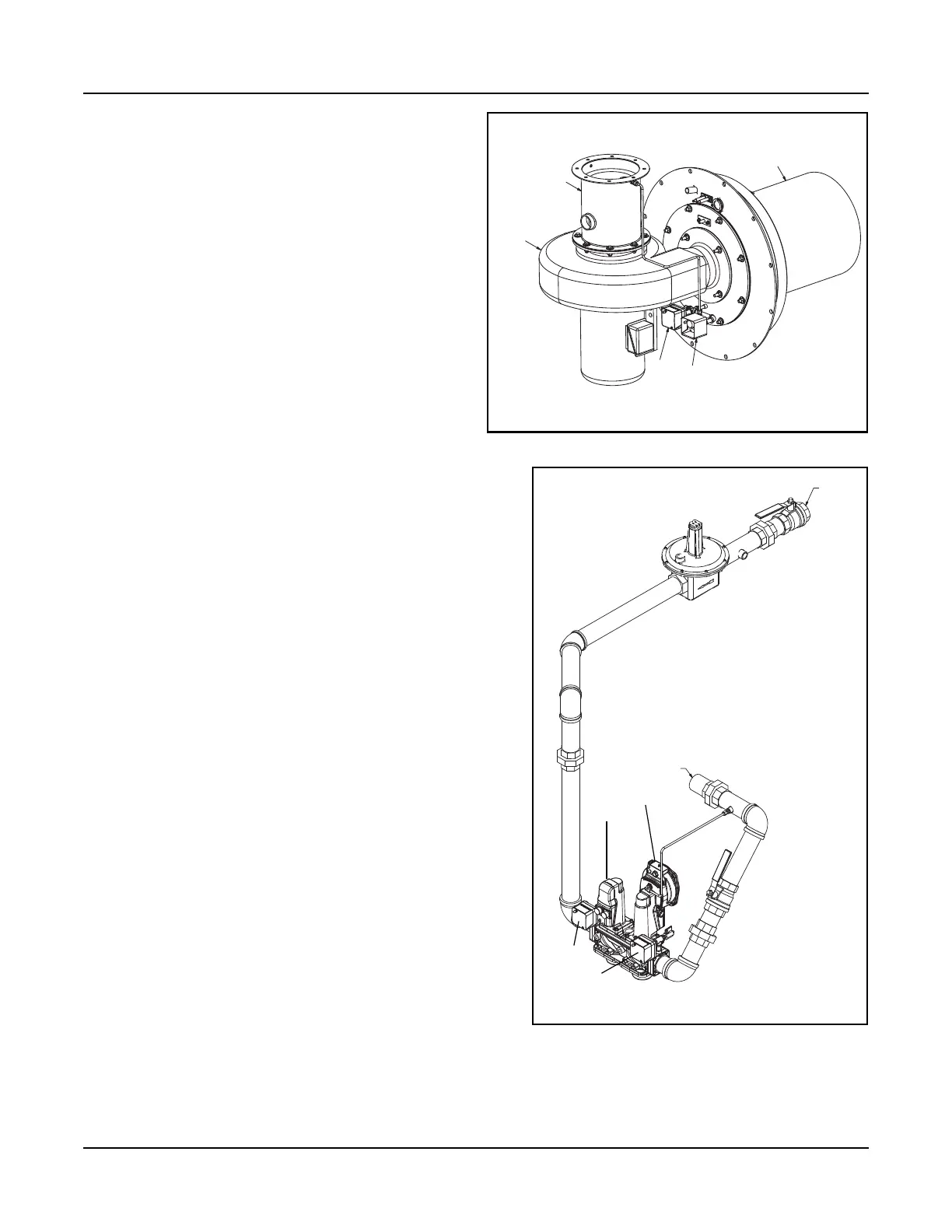

1.2.3. Burner Gas Train

The gas train assembly is provided in accordance with UL

certification and complies with ASME CSD-1. The gas train

assembly is factory assembled and wired, consisting of the

following components:

A. Low Gas Pressure Switch - manual reset

B. High Gas Pressure Switch - manual reset

C. Single body, dual safety motorized shut-off valves

with POC and regulating actuator

D. Manual Shutoff Butterball Valve

E. Regulator (optional, based on gas supply pressure)

F. Test cocks

1.2.4. Controls

The Falcon hydronic control is an integrated burner

management and modulation control with a touch-screen

display/operator interface.

The controller is capable of the following functions:

• Two (2) heating loops with PID load control.

• Burner sequencing with safe start check, pre-purge, pilot

ignition, and post purge.

• Electronic ignition.

• Flame Supervision.

• Safety shutdown with time-stamped display of lockout

condition.

• Variable speed control of the combustion fan.

• Supervision of low and high gas pressure, air proving, stack

back pressure, high limit, and low water.

• First-out annunciator.

• Real-time data trending.

• (3) pump/auxiliary relay outputs.

• Modbus communication capability.

• Outdoor temperature reset.

• Remote firing rate or setpoint control

• Setback/time-of-day setpoint

• Lead/Lag for up to 8 boilers

CAPS

HAPS

VENTURI

BURNER CANISTER

BLOWER

ASSEMBLY

Figure 1-1 Burner Assembly

GAS INLET

TO VENTURI

A

B

C

E

E

F

Figure 1-2 Gas Train (8000 shown)

D

Loading...

Loading...