Appendix C Gas Valve

C-30

7. Tighten the scr ews on the metal strain relief.

The maximum tor que for each metal str ain relief scr ew

is 4.4 in-lb (0.5 Nm).

8. Assemble

-

9. R oute the “pig-tailed” wires from the valve connector

through the 1/2” conduit and to the nearest conduit body

(panel), and then screw the valve connector to the 1/2”

NOTE: It may be necessary to pull the wires at the nearest

conduit body to reduce any potential wire slack in the raceway

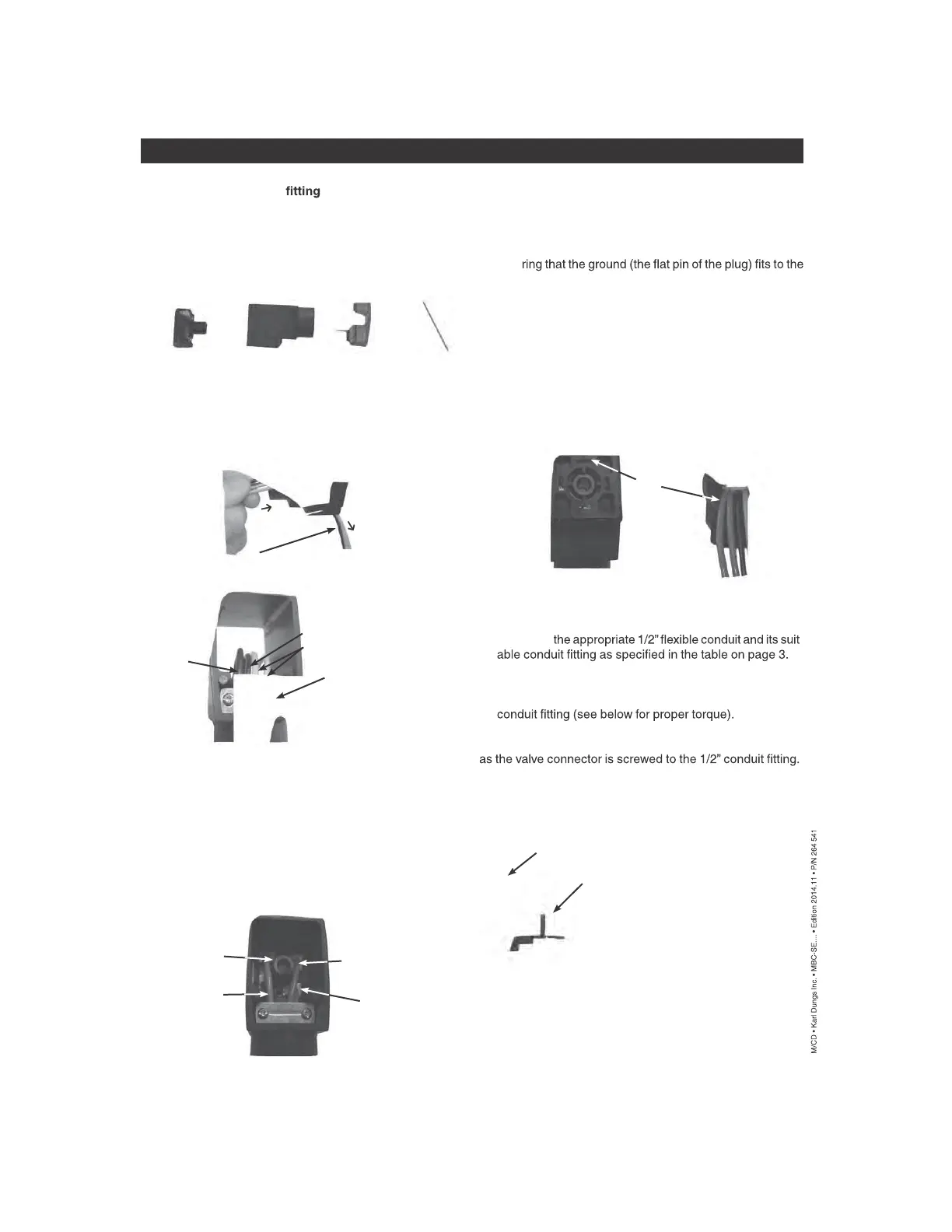

10. Assemble the cover and mounting screw to the valve con -

nector, and mount the valve connector to the valve coil as

shown below.

11. Tighten the mounting scr ew.

12. Follow NEC (NFPA 70) requirements for proper termination

at the nearest conduit body.

Failure to follow the exact instructions belo w ma y result

in a valve connector not

to valve.

STEPS

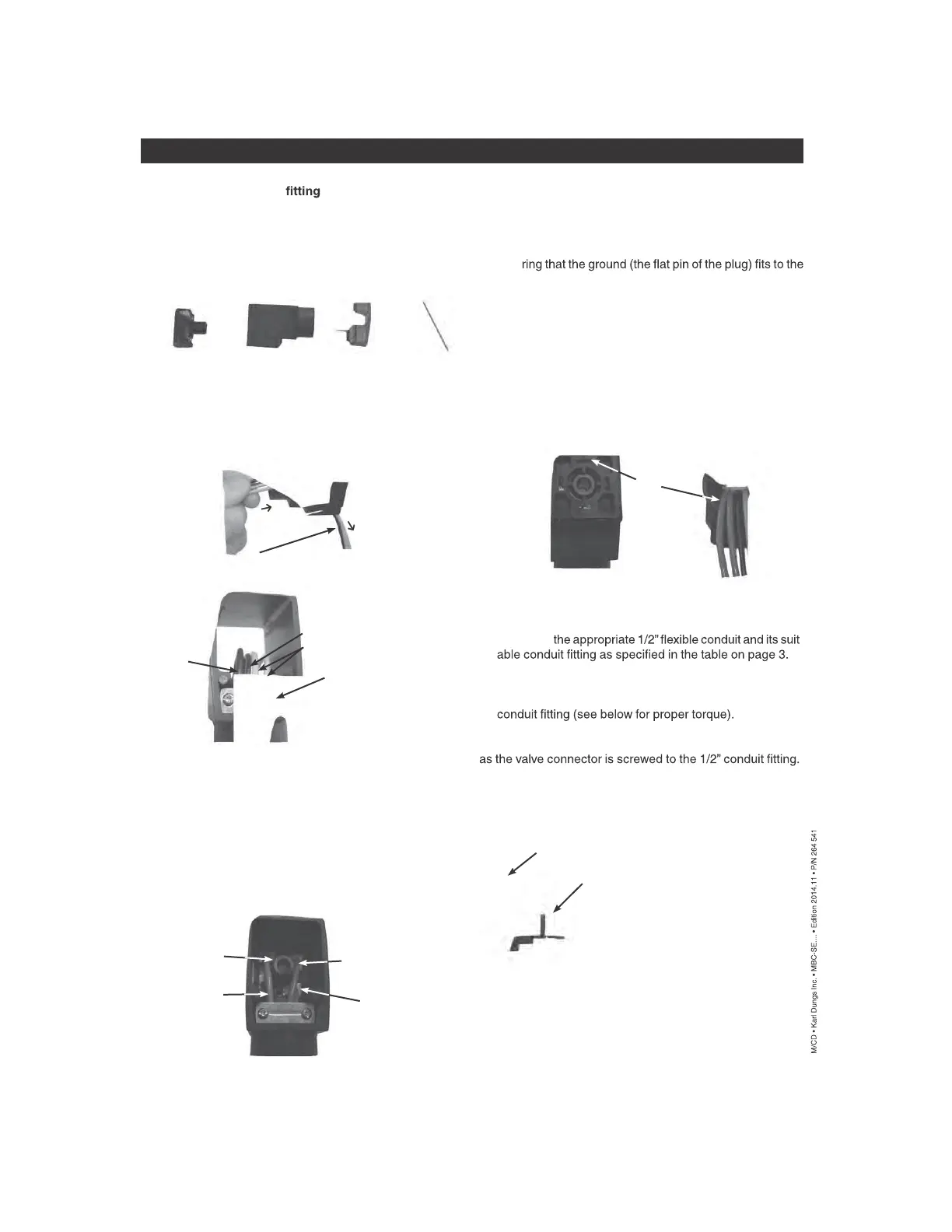

1. After selecting the pr oper number of wires, push the mount -

ing screw completely out from the valve connector and

disassemble the remaining 4 parts as shown below:

2. Star ting from the 1/2” NPT end of the housing, push the

wires under the metal strain relief and through the housing

(see FIG. A below). The GREEN (ground) wire should be

placed into the far left groove when viewed as shown in

FIG. B. The “Neutral (-) ” should be placed into the groove

next to the GREEN (ground).

3. Continue to push the wir es through the housing until there

is at least an extra 3”- 6”available for connecting the wires

to the terminals on the T-Block (see FIG. A above).

4. Strip no mor e than 1/4” of insulation from each wire.

5. Wiring to the corr ect terminal is critical. The terminals are

labeled next to the terminal screws. Terminate each wire to

its proper terminal on the T-block. See FIG. C to determine

the proper terminals for the valve. NOTE: One neutral is

used to power both valves.

Mounting Screw

Terminal Block

(T-Block)

Cover

The maximum torque at the 1/2” NPT conduit

housing connection is 60 in-lb (6.75 Nm).

Fig. A

Strip the end of each

lead 1/4” maximum

push wires

pull 3”-6” of extra wire

Neutral -

Metal Strain

Relief

Ground

Fig. B

Fig. D

Ground

Fig. E

The maximum torque for mounting

screw is 8.8 in-lb (1.0 Nm).

Housing

The maximum tor que for the terminal scr ews is 4.4 in-lb

(0.5 Nm).

6. Pull the wires so that the T-Block is completely pulled into

the housing. As the T-Block gets pulled into the housing,

the T-Block and the wires must be properly guided into the

housing by:

A) Ensu

front of the housing as shown in FIG. D below,

AND

B) Ensu ring that the wires lay side-by-side beneath the metal

strain relief as shown in Fig. E below,

AND

C) Organizing the wires so that they terminate on the same

side of the connector under which they were routed. The

wires must NOT crisscross inside the housing to the op -

posite side from which they are terminated. Fig. C illustrates

how the wires terminate on the same side under which they

were routed.

Terminal #2

Hot (+) for valve #1

Terminal #3

Hot (+) for valve #2

Ground

Terminal #1

Neutral (-)

Fig. C

Hot +

Electrical DIN Connector assembly & wiring

Loading...

Loading...