Section 3 — Stack and Intake Vent Sizing and Installation

Part No. 750-363 3-15

D. Under no condition should the total area of the air supply

openings be less than one square foot.

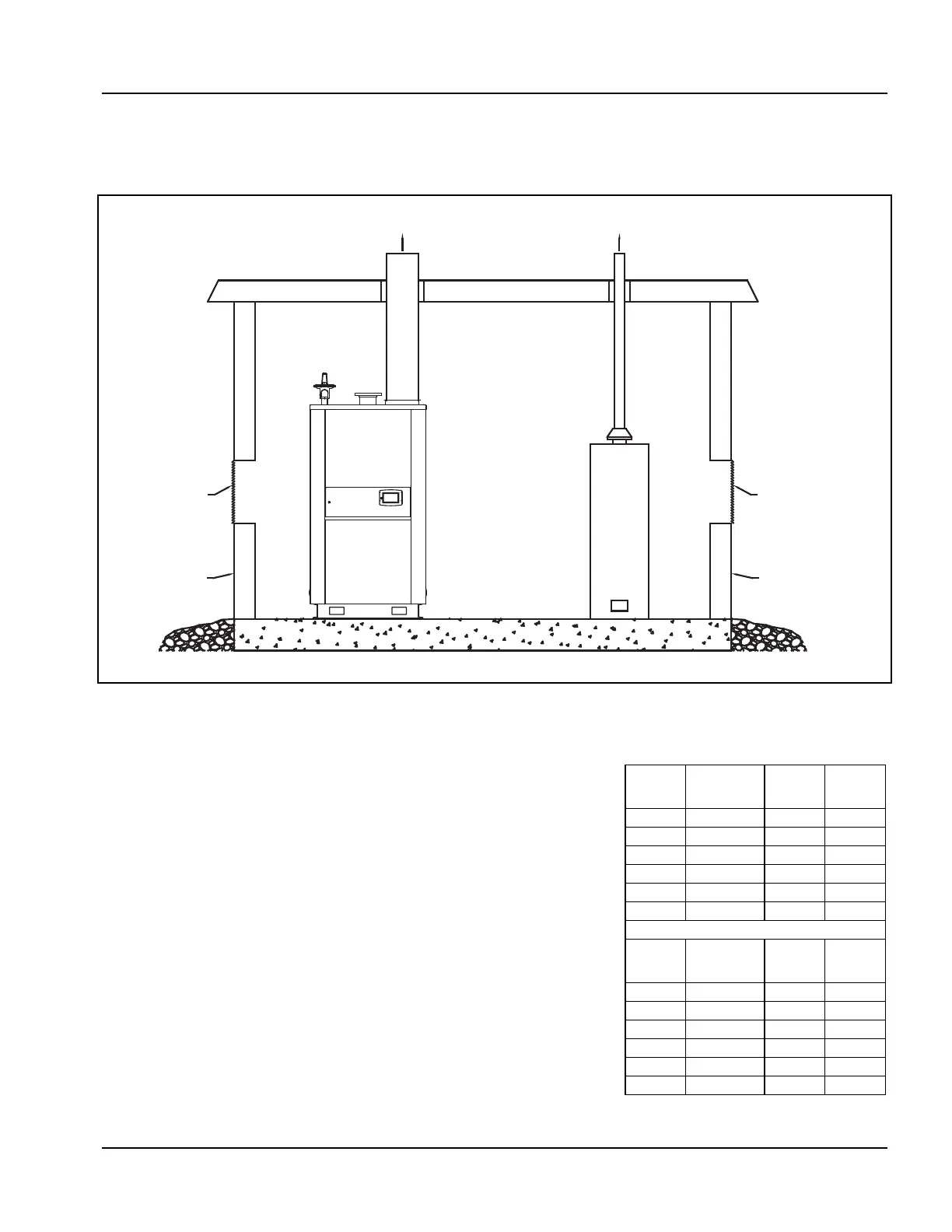

Figure 3-7. Two Opening Engineered Method

E. Size the openings by using the formula:

Area in square feet = cfm/fpm

Where cfm = cubic feet per minute of air

Where fpm = feet per minute of air

2. Amount of Air Required (cfm).

A. Combustion Air = 0.25 cfm per kBtuh.

B. Ventilation Air = 0.05 cfm per kBtuh.

C. Total air = 0.3 cfm per kBtuh (up to 1000 feet elevation.

Add 3% more per 1000 feet of added elevation).

3. Acceptable air velocity in the Boiler Room (fpm).

A. From floor to 7 feet high = 250 fpm.

B. Above 7 feet above floor = 500 fpm.

Example: Determine the area of the boiler room air supply openings

for (2) CFLC 4000 boilers at 750 feet elevation. The air openings to

be 5 feet above floor level.

• Air required: 4000 x 2 = 8000 kBtuh. From 2C above,

8000 x 0.3 = 2400 cfm.

GAS

VENT

WATER

HEATER

GAS

VENT

EXTERIOR WALL

FRESH AIR OPENING

EXTERIOR WALL

FRESH AIR OPENING

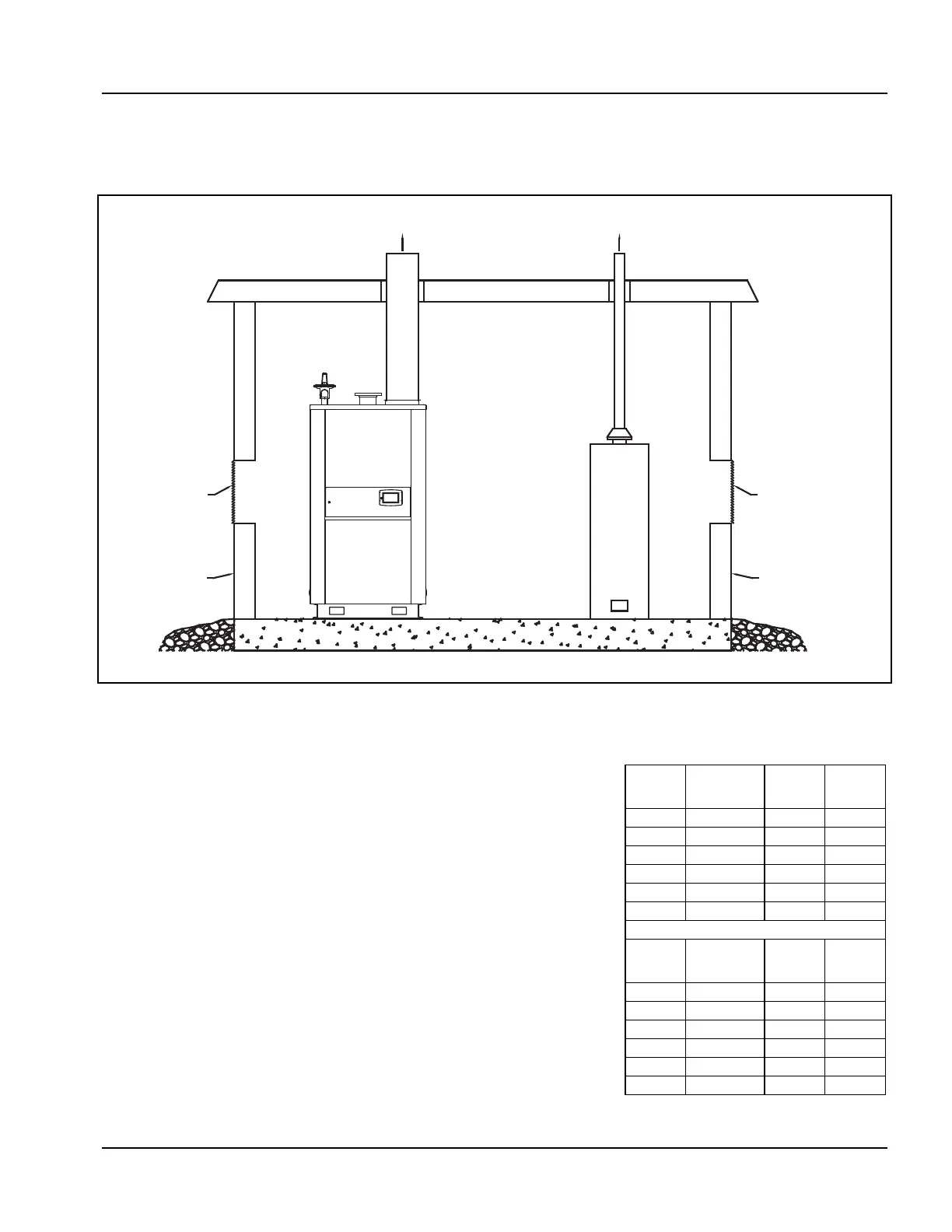

Table 3-1 Boiler room air

CFLC

20 ppm

Combustion

air SCFM

Vent air

SCFM

Total

room air

SCFM

4000 1000 200 1200

5000 1250 250 1500

6000 1500 300 1800

8000 2000 400 2400

10000 2500 500 3000

12000 3000 600 3600

CFLC

9 ppm

Combustion

air SCFM

Vent air

SCFM

Total

room air

SCFM

4000 1075 200 1275

5000 1350 250 1600

6000 1625 300 1925

8000 2150 400 2550

10000 2700 500 3200

12000 3225 600 3825

Loading...

Loading...