Section 3 — Stack and Intake Vent Sizing and Installation

3-10 Part No. 750-363

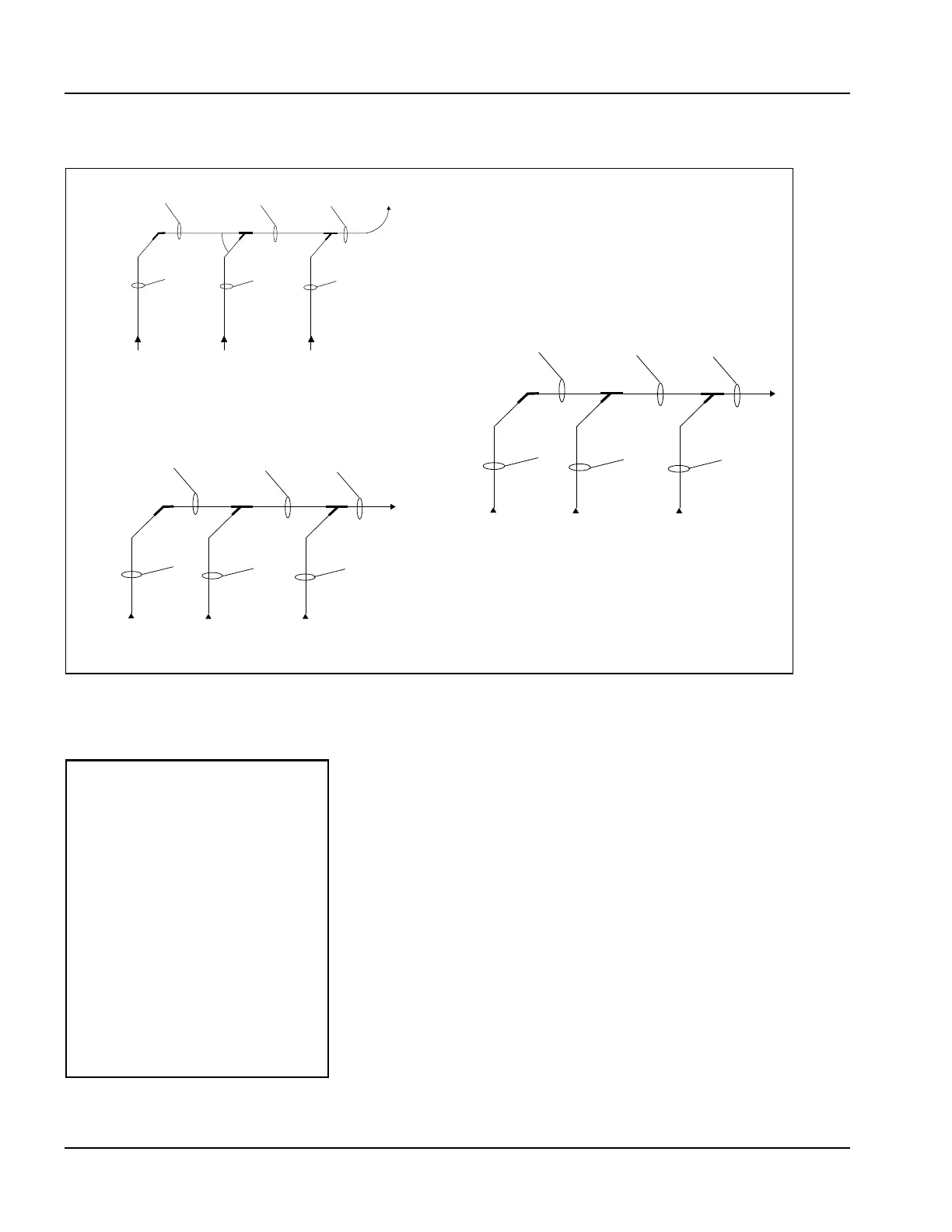

EXAMPLE 3

3.5 COMBUSTI0N AIR/BOILER ROOM

VENTILATION REQUIREMENTS

The boiler(s) must be supplied with adequate quantities of

uncontaminated air to support proper combustion and equipment

ventilation. Air shall be free of chlorides, halogens, fluorocarbons,

construction dust or other contaminants that are detrimental to the

burner/boiler. If these contaminants are present, we recommend the

use of direct vent combustion provided the outside air source is

uncontaminated.

Combustion air can be supplied by means of conventional boiler

room venting, where ambient combustion air is drawn from the area

immediately surrounding the boiler (boiler room must be positive

pressure*), or with air ducted from the outdoors to the burner

cabinet (direct venting) or burner air intake (sealed combustion). All

installations must comply with local Codes and with NFPA 54 (the

National Fuel Gas Code - NFGC) for the U.S. and for Canada, CAN/

CGA B 149.1 and B 149.2.

*A boiler room exhaust fan is not recommended as this type of device can cause

a negative pressure in the boiler room if using a conventional wall louvered air

intake.

14”

14” 14”

14”

From Boilers

14”

14”

16”

24”

30”

16” 16”

16”

From Boilers

45

o

26”

26”

26”

14” 14”

14”

3

From boilers

to roof

vent

GOOD

BAD

GOOD

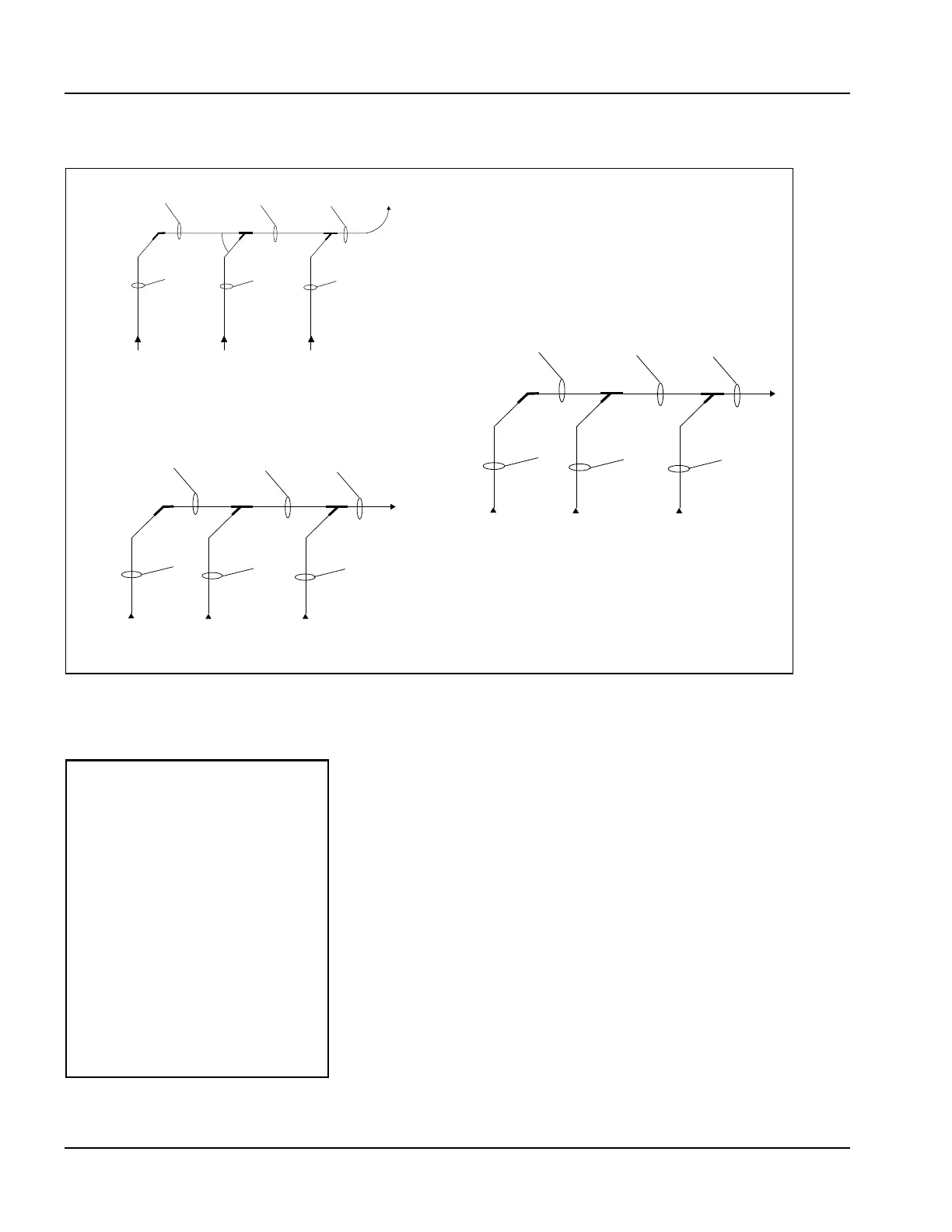

Combustion air methods

ROOM AIR

Air is drawn from the boiler room.

DIRECT VENTING

Air is ducted from the outdoors to

the burner cabinet. No direct

connection to burner air intake.

SEALED COMBUSTION

Outside air is ducted directly to

the burner air intake.

Loading...

Loading...