Section 4 — Commissioning

4-20 Part No. 750-363

Configurable Pump/Aux Relay Contacts

The Falcon Pump/Aux Relay outputs are configurable by means of six pre-configured Pump Control Blocks.

Each control block is configured for a specific application:

1. Central Heat Pump

2. Boiler Pump (for primary/secondary pumping)

3. DHW pump

4. System Pump

5. “Aux 1 Pump” - used for a boiler isolation valve

6. “Aux 2 Pump” - used for a boiler Start Permissive Interlock

Each pump control block has seven parameters (for details see Falcon Lead Lag appendix):

Pump Options (2 parameter blocks) - determine pump on/off conditions

Start Delay - if burner is just starting up, timer will delay pump turning on

Overrun Time - keeps the pump running for a short time after the input turns off or demand is satisfied

Output Connection - selects Pump A, B, or C (refer to WD, Figure 2-10)

Cycle Count - one cycle counter for each pump output; can be reset if a pump is replaced

Pump Control - selects Auto or Manual control

A Pump Exercise routine helps to prevent pumps from freezing up due to long periods of inactivity.

Configurable parameters are Pump Exercise Interval (days) and Pump Exercise Time (minutes). Any pump

that remains off for the Pump Exercise Interval will be turned on for the duration given by Pump Exercise

Time.

The relays may be configured for various other functions, including freeze protection, isolation valves,

damper interlocks, operating status, etc.

Annunciator

The Annunciator monitors the Falcon control circuit to provide fault and status messages, and also provides

first out annunciation for interlock lockouts. Eight inputs are available in addition to the Interlock, Load

Control, and Pre-Ignition Interlock inputs, totaling 11 monitored points. Annunciator points can be accessed

via the Falcon display Operation screen.

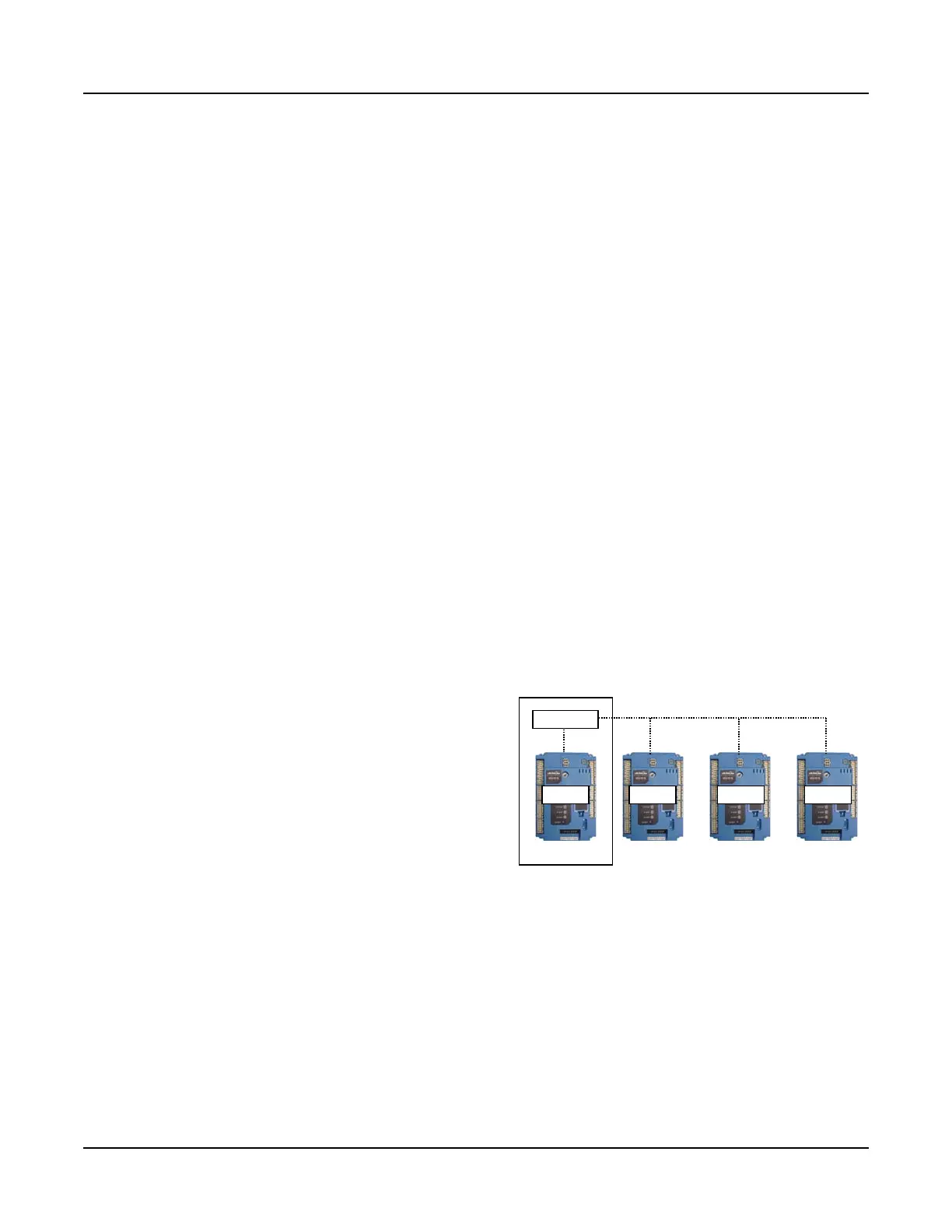

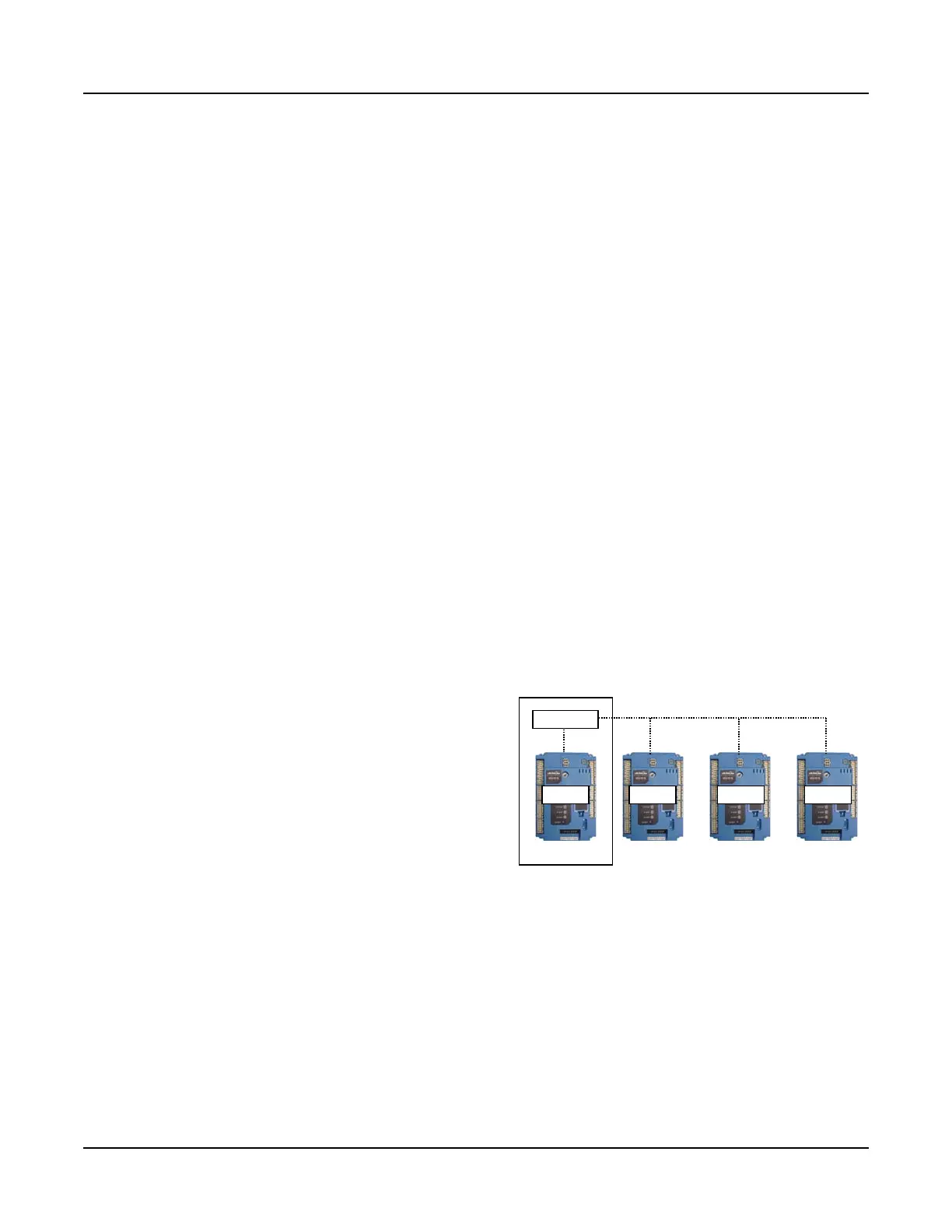

Lead/Lag Control (up to eight boilers)

Multiple Falcon units can be connected in a lead/lag

system. Controllers in a lead/lag configuration

communicate over the Falcon’s MB2 Modbus network.

One Falcon in the lead/lag network hosts the Lead Lag

Master function, which coordinates the activities of the

Slave units (individual Falcons, including the one hosting

the Master) via Modbus. The Master uses its host

controller’s header sensor to receive control input

information and to maintain the optimum setpoint. An

outdoor temperature sensor can also be connected for

Lead Lag outdoor reset control.

Boiler sequencing, on/off staging, and firing rate allocation are user-configurable. The Falcon’s default lead

lag parameter settings have been optimized specifically for ClearFire-C condensing boiler operation.

Refer to the Falcon Lead/Lag appendix in this manual for additional information.

Modbus Communication

For remote enable / remote setpoint (see above) and for remote monitoring through a building EMS, the

Falcon uses the Modbus communication protocol. For more information on Modbus setup and

implementation, see the Falcon Lead Lag appendix in this manual.

SLAVE SLAVE SLAVE SLAVE

MASTER

Figure 4-13 Falcon Lead/Lag

Loading...

Loading...