Appendix C Gas Valve

C-32

MBC...SE

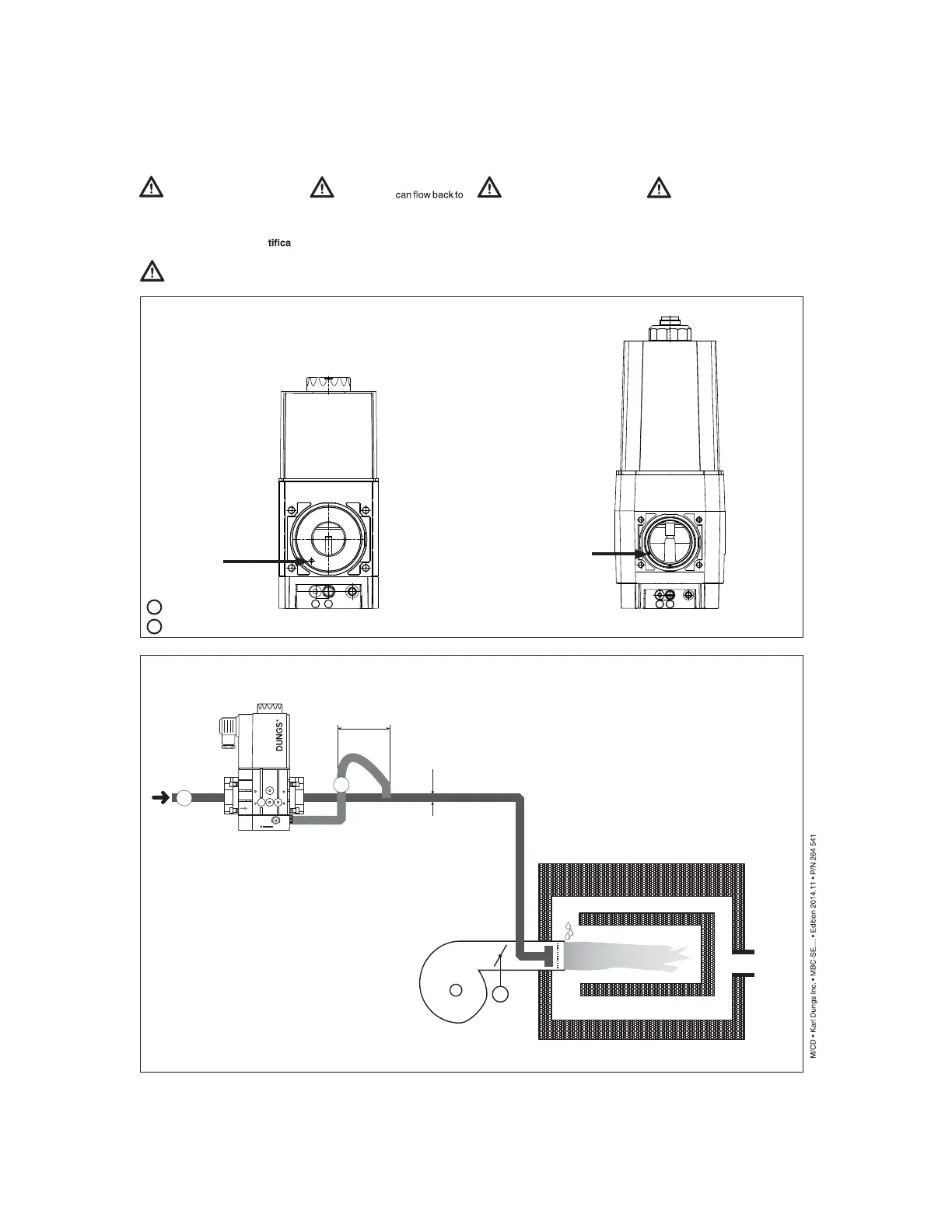

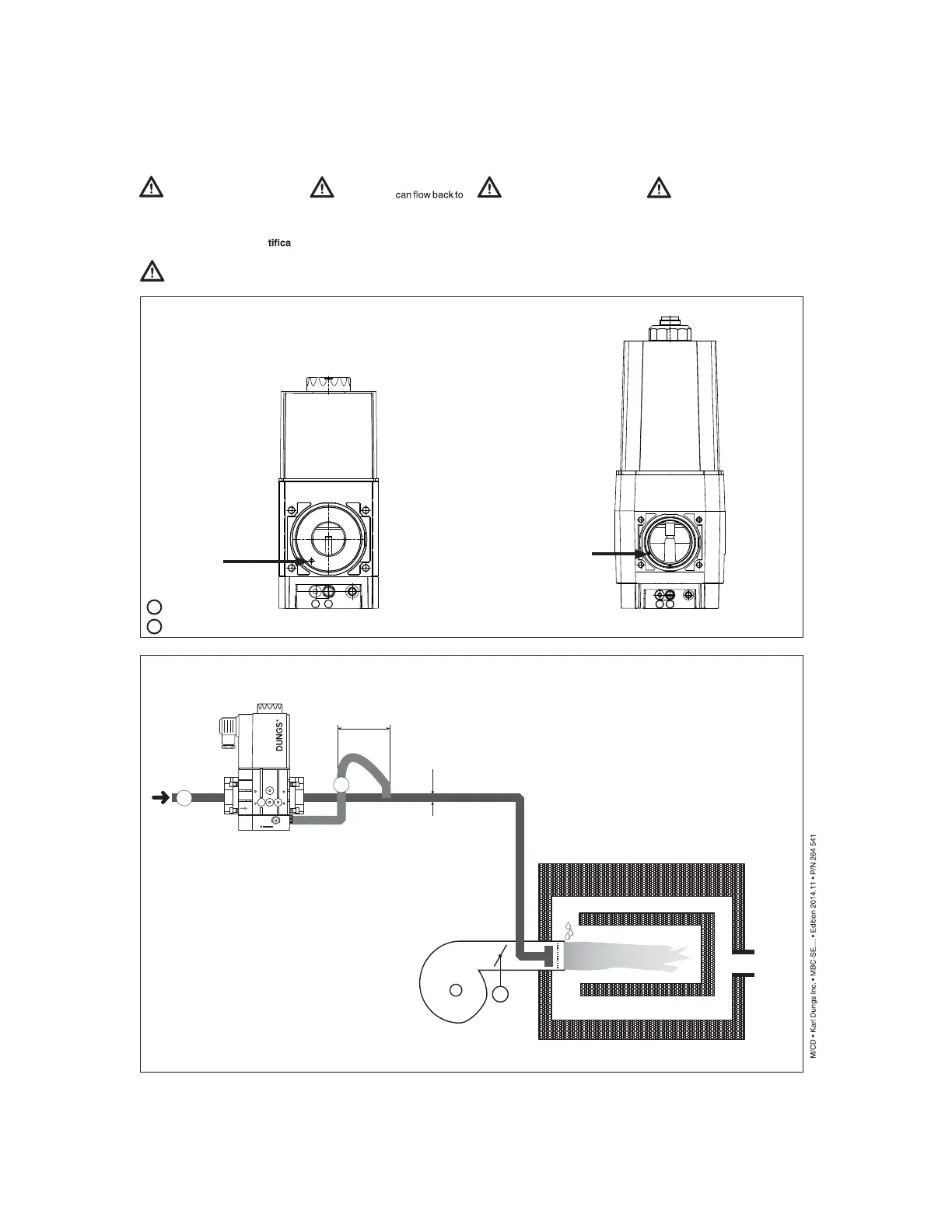

Recommended Installation of Impulse lines when used (optional)

M

1

2

20

16

12

8

4

p

Br

min. 5 x

Diameter

Diameter

External Impulse line (option)

Assembly Instructions

Impulse line p

BR

must cor -

respond to ≥ DN 4 (1/8”), PN

1 and they must be made of steel.

Other materials for Impulse lines

are only per mitted after a cer

-

tion with the burner / boiler.

Close internal Impulse line

with grub scr ew. See Fig. 1

Route Impulse line so that no

condensate

the MBC...SE. See Fig. 2

1 2

1

2

MBC 1000/2500

Fig. 1

MBC 4000

Secure Impulse line to prevent

them from being ripped out and

deformed.

Keep Impulse line short!

Test Impulse line for external

leakage. Use leakage spray

only if necessary.

Te st pr e s s ur e :

p

max.

= 40” W.C.

Close this port

with grub screw

if using external

feedback

Close this port

with grub screw

if using external

feedback

1

2

external feedback

breathing port

Loading...

Loading...