Section 4 — Commissioning

Part No. 750-363 4-17

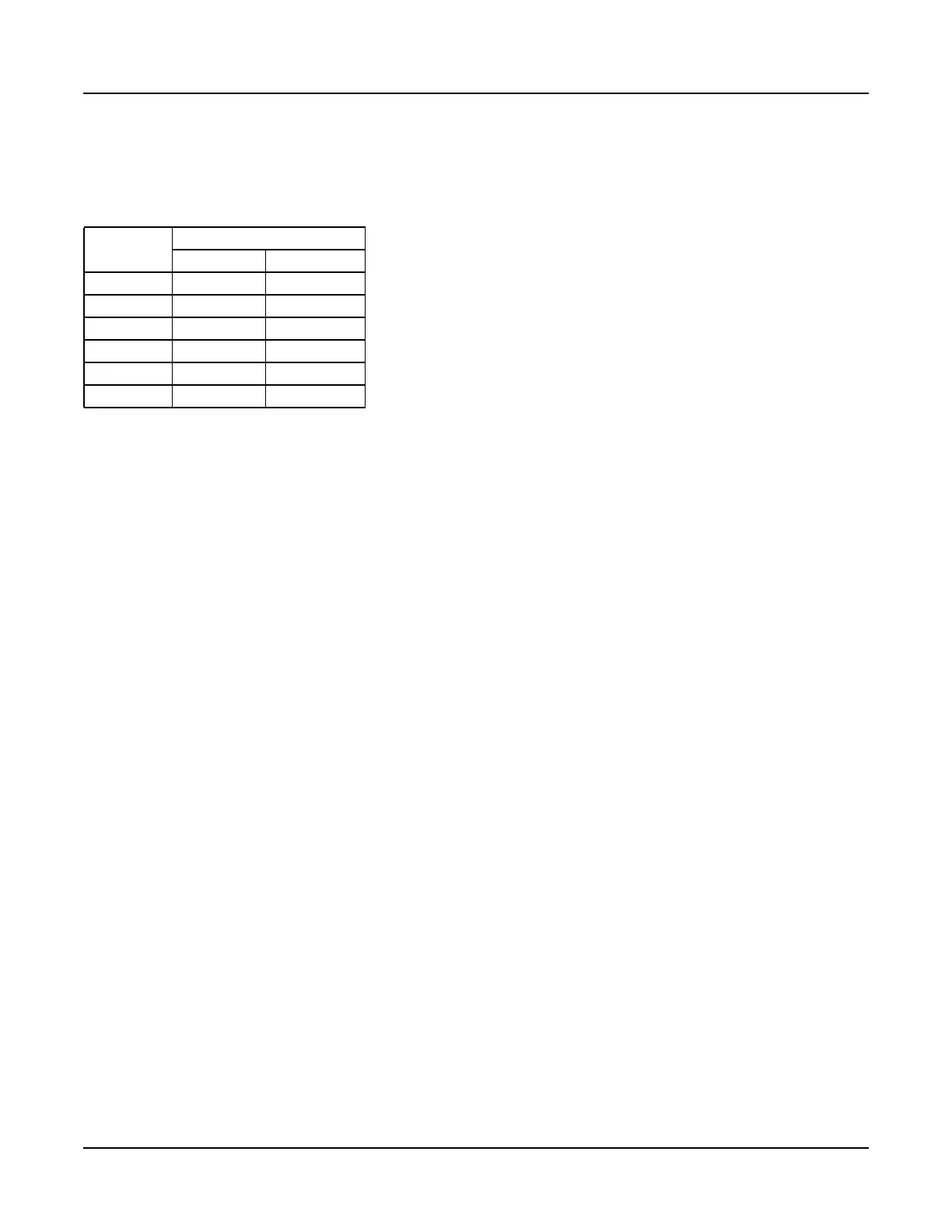

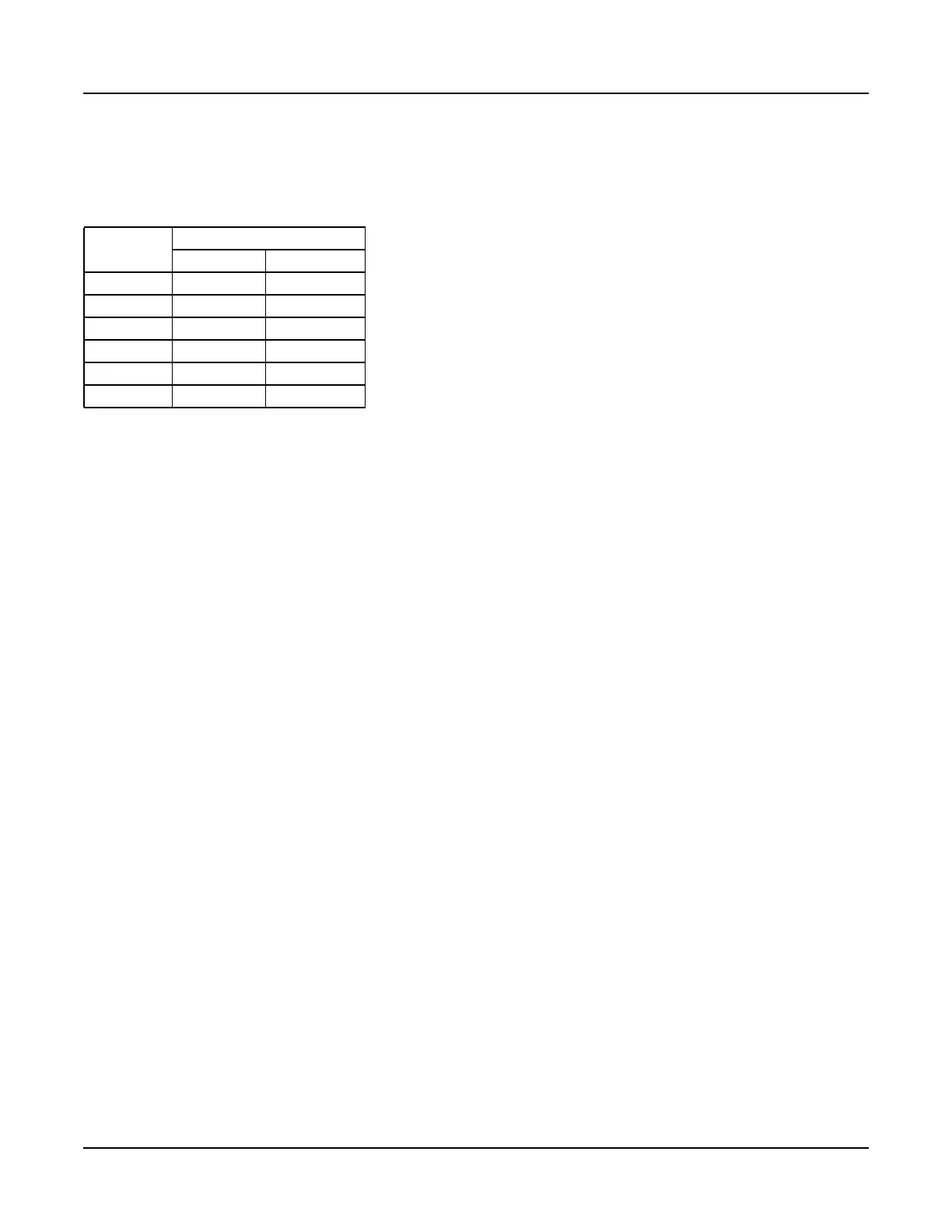

4.10.9 High Air Pressure Switch Settings

The High Air Pressure Switch (HAPS) is used to safely shut down the boiler in case of a blocked flue or

blocked condensate condition. The HAPS has a manual reset, similar to the High/Low gas pressure

switches.

Table 4-2 HAPS Settings

Note: In the event of a HAPS lockout, investigate possible causes before attempting to restart boiler.

4.10.10 Limit Controls Check

The Modulation Off (operating limit) and High Limit functions can be tested while the boiler is operating by

adjusting the respective setting downward and allowing the boiler outlet temperature to rise. The

Modulation Off point is the sum of the Modulating setpoint and the Hysteresis Off value. The Modulation

On point is the setpoint minus the Hysteresis On value.

When the boiler’s outlet temperature exceeds either of these settings, the boiler will shut down. When the

operating limit is exceeded, the boiler will automatically recycle upon the outlet temperature dropping below

the on point. When the High Limit is exceeded, a lockout should result requiring a manual reset of the

control after the temperature has dropped below the high limit setting.

Before testing the High Limit, temporarily set the Modulation OFF point higher than the High Limit setting.

Restore Modulation OFF and High Limit to operational settings after testing.

Specific settings are determined by application. Maximum High Limit for Model CFLC is 250 deg F.

The High Limit setting is considered a safety parameter. Any changes made will require a password login

and reset of the Falcon.

4.11 POST START-UP CHECKOUT PROCEDURE

1. Ensure proper air venting to expansion tank.

2. Set high gas pressure switch to 50% higher than operating gas pressure at low fire. Set low gas pressure switch to

50% lower than operating gas pressure at low fire.

3. Check the draft on the outlet stack on each boiler, compare to acceptable limits (-.25 to +.25” W.C.) and record in

start up form. Operating outside of acceptable limits could result in light off and flame failure problems.

4. Switch to automatic operation and monitor flue gas to ensure consistent excess air.

5. Reassemble all panels and covers that were removed and replace any plugs that were removed to check gas

pressure.

6. Verify HAPS switch operation by simulating a blocked flue condition.

7. Verify gas pressures remain within limits shown in Table 4-1.

8. Provide instructions to owner and operators on operation, safety and maintenance of the equipment.

9. Provide instructions to owner and operators on proper water treatment guidelines and procedures.

Boiler Size Setting (inches WC)

20 ppm 9 ppm

4000 5 5

5000 6 7

6000 11 16

8000 21 21

10000 15 8

12000 9 9

Loading...

Loading...