Section 2 — Installation

2-6 Part No. 750-363

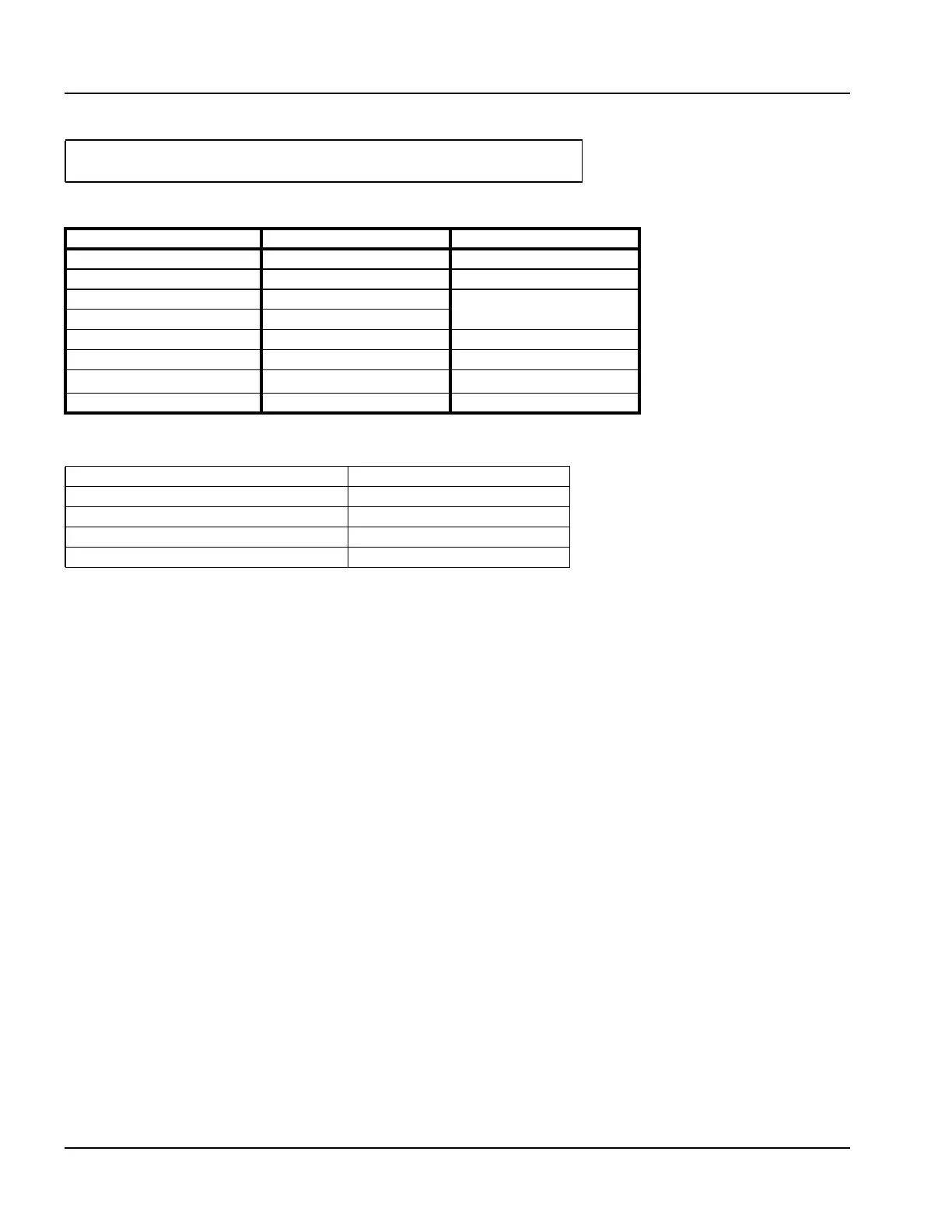

Table 2-2 Model CFLC Water Chemistry Requirements

2.5 BOILER FLUSH

Cleaver-Brooks recommends cleaning in accordance with the recommendations of the boiler owner’s water treatment

company for each individual site. The boiler may be flushed with or without heat applied, as deemed appropriate by the

chemical treatment company. A traditional steam “Boil Out” is not required on Cleaver-Brooks hot water boilers.

Following are some general recommendations to help ensure long boiler life and efficient operation.

NOTE: these are recommendations only. The chemical treatment supplier should recommend a procedure based on

the site conditions and quality of water being used to fill the system.

If the entire system is being flushed THROUGH the boiler, weld slag and deposits from the piping system may settle in

the boiler. The boiler is typically a low velocity zone where these deposits tend to accumulate. The boiler should be

drained periodically during the flushing process to keep any deposit build up to a minimum. When the system flush is

complete, drain the boiler completely and open water side inspection ports for visual inspection. Any deposits should be

manually flushed out.

If the boiler is isolated during the system flush, or if this is an equipment replacement only where minimal amounts of

system piping have been replaced, there should be minimal manufacturing deposits inside the boiler and no boiler flush

is required.

To provide the longest life of the equipment it is recommended but not mandatory to chemically treat the boiler prior to

start-up. The owner’s water treatment company should determine needed course of action for each installation.

2.6 USING GLYCOL

The Model CFLC boiler may be operated with a solution of glycol and water. Where glycols are added, the

system must first be cleaned and flushed. Correct glycol selection and regular monitoring of the in-use

concentration and its stability is essential to ensure adequate, long-term freeze protection, including

protection from the effects of glycol-derived corrosion resulting from glycol degradation.

Note: Corrosion and sludge deposits in old systems must be removed

prior to installation of a new boiler.

Parameter Limit Means of control

Glycol 25-50% Glycol fill/mixing station

pH 8.3 - 10.5 Buffering agent

Nitrates 50 ppm

Chemical additives

Sulfates 50 ppm

Chloride < 250 ppm

Oxygen < 0.1 ppm Air separator/eliminator

Specific Conductivity

< 3500 mmho/cm

Total Hardness < 10 ppm Softener

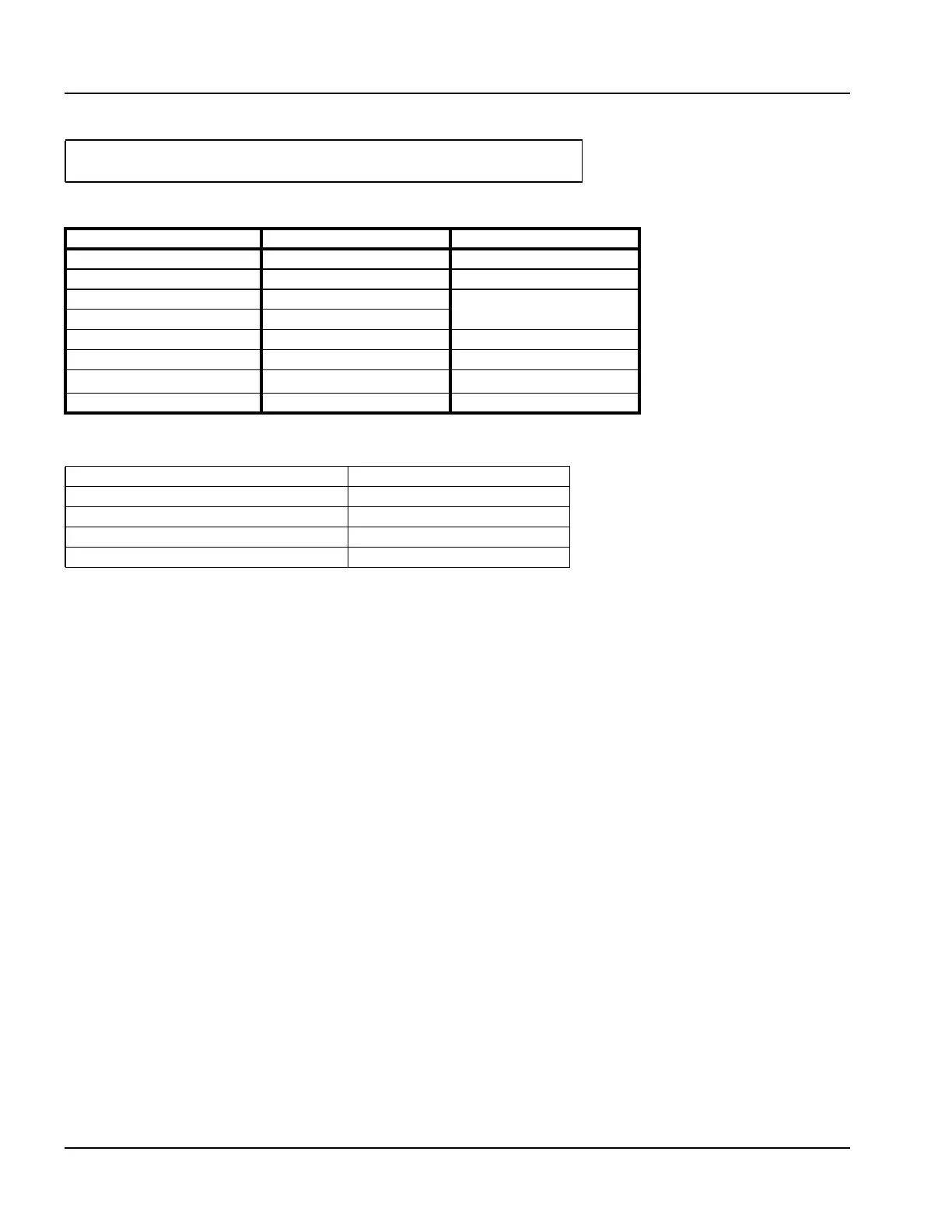

Table 2-3 Model CFLC Water Temperature Data (Non-Glycol)

Minimum inlet temp. 33

o

F

Maximum operating supply set point temp. 230

o

F

Maximum design temp. 250

o

F

Minimum supply set point temperature 130

o

F

Max allowable Delta T 100

o

F

Loading...

Loading...