Section 2 — Installation

Part No. 750-363 2-11

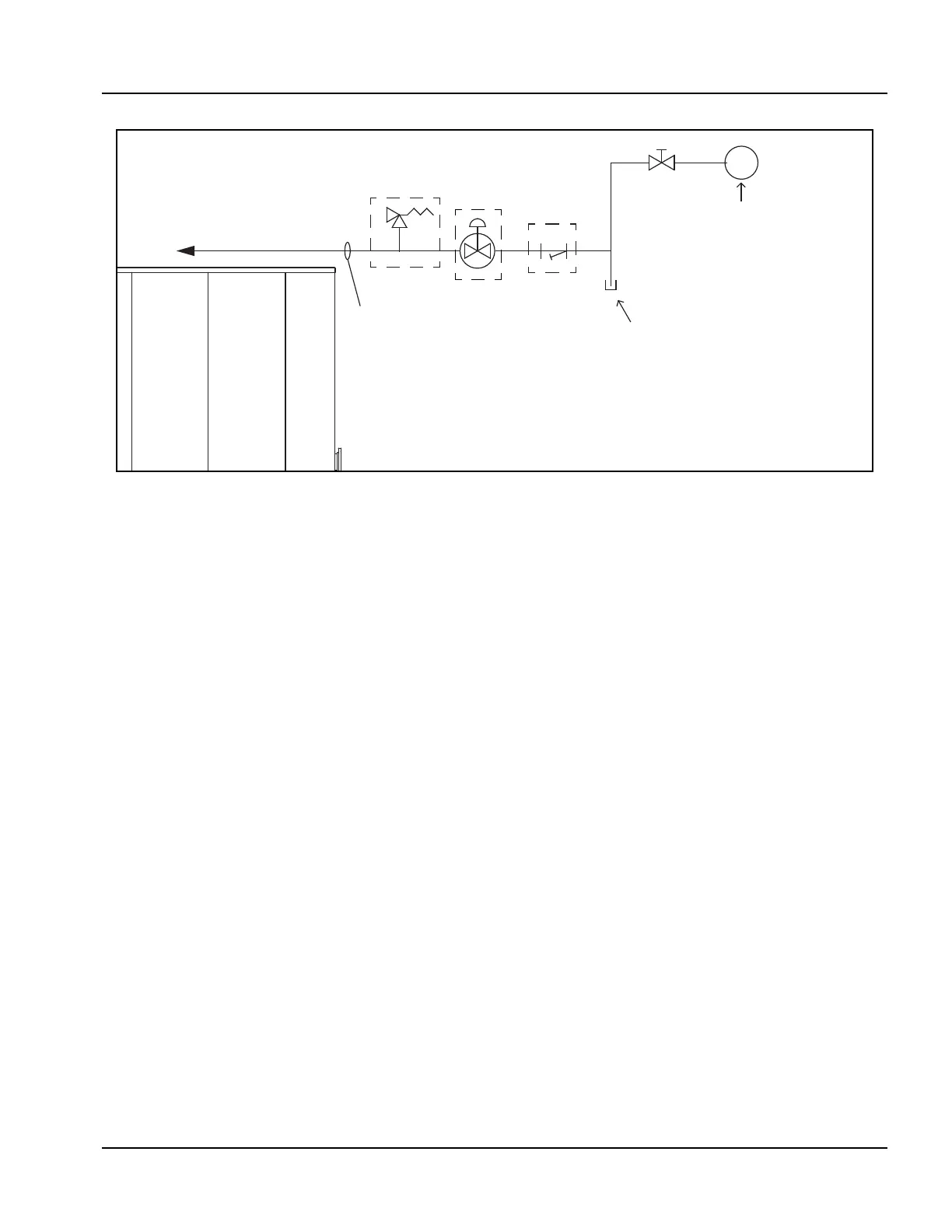

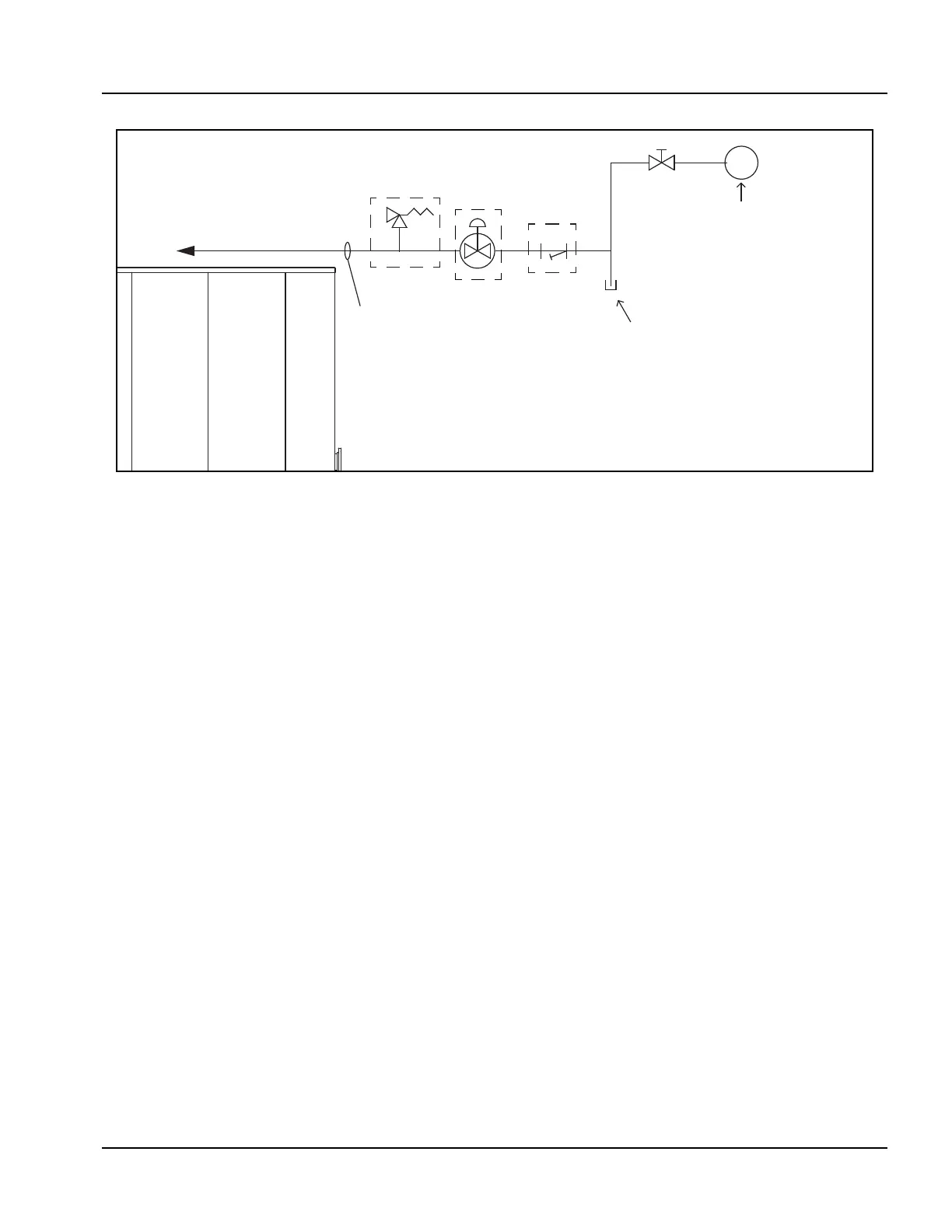

Figure 2-5 Gas Piping

2.7.5 Gas Supply Pipe Sizing

For proper operation of a single unit or a multiple unit installation, CB recommends that the gas piping be

sized to allow no more than 0.3" w.c. pressure drop from the source (gas header or utility meter) to the final

unit location. Higher supply pressure systems may allow for a greater pressure drop. In ALL cases, minimum

supply pressures must be met for proper operation of the boiler(s). The gas supplier (utility) should be

consulted to confirm that sufficient volume and normal pressure are provided to the building at the

discharge side of the gas meter or supply pipe.

For installations of new boilers into an existing building, gas pressure should be measured with a

manometer to ensure sufficient pressure is available. A survey of all connected gas-using devices should be

made. If appliances other than the boiler or boilers are connected to the gas supply line, then a

determination must be made of how much flow volume (cfh) will be demanded at one time and the pressure

drop requirement when all appliances are firing.

The total length of gas piping and all fittings must be considered when sizing the gas piping. Total equivalent

length should be calculated from the utility meter or source to the final unit connection. As a minimum

guideline, see gas piping Tables 2-6 and 2-7. The data in these tables is from the NFPA 54 source book,

2006 edition.

To verify the input of each device that is connected to the gas piping, obtain the btu/hr input and divide this

input by the calorific value of the gas that will be utilized. For instance, a unit with 4,000,000 btu/hr input

divided by a gas calorific value of 1060 will result in a flow of 3774 cfh. The single boiler is approximately

20 feet from the gas supply header source. And with a measured gas supply pressure of 10" w.c. we find

from Table 2-6 that a supply pipe size of 3" should be used as a minimum.

Same or larger than boiler gas connection

size

Drip leg required for any vertical run of

piping

As required

Gas header - size for boiler room

capacity and to minimize pressure loss

As required

TO GAS TRAIN

As required

Loading...

Loading...