AUSTROMAT

®

664 iSiC

®

/ 674 baSiC

2

7. Maintenance and Service

Operating Instructions (Version 03/2018) 113

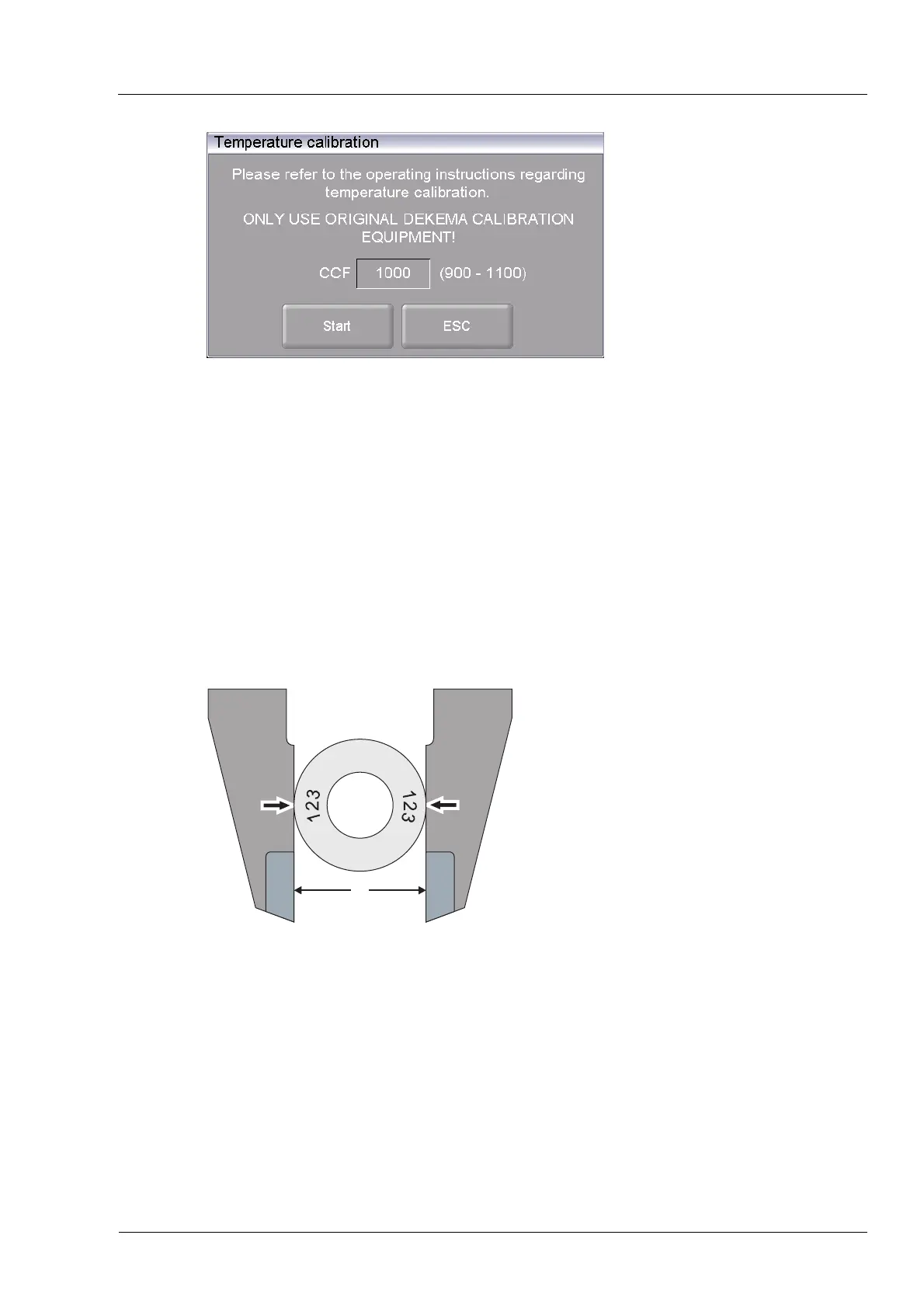

Fig. 7-2 Starting the temperature calibration

4. When the program is finished let the sintered PTC ring cool down on the sinter plate.

5. Use an appropriate auxiliary tool, e.g. tweezers, or wear safety gloves when removing the

PTC ring. Place the PTC ring (cooled down to room temperature) on a clean even surface.

NOTE:

In order to exactly determine the diameter it is recommended to forward the sintered PTC

ring to your service partner or to DEKEMA.

6. Use a caliper gauge in order to determine the diameter of the sintered PTC ring.

• The measurement accuracy must be better than ± 0.01 mm (= 10 µm). Otherwise, an

exact evaluation and temperature calibration cannot be guaranteed.

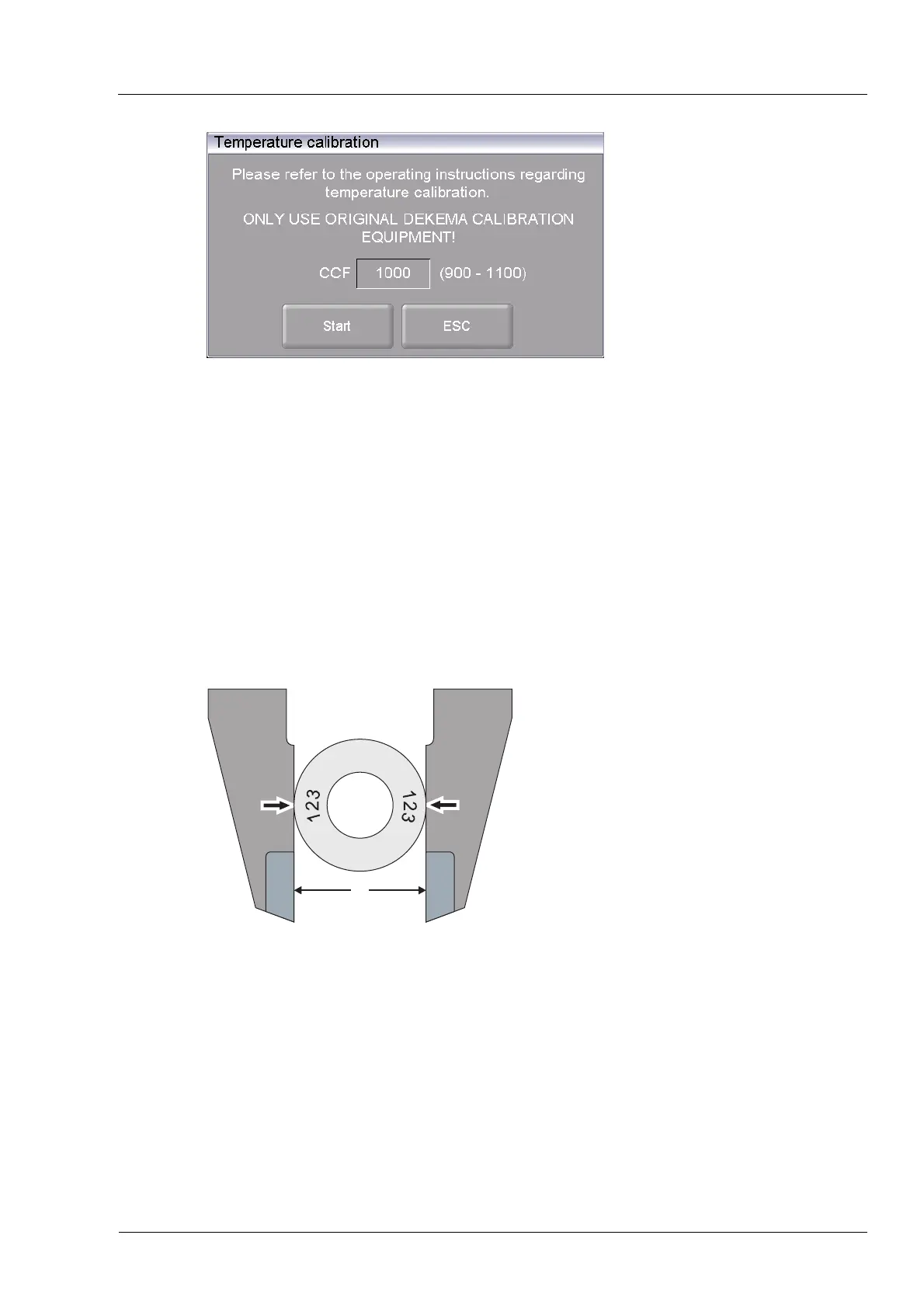

• Measure the diameter D between the two center digits of the three-digit batch number

of the PTC ring (for example, the "2" digits in the following figure).

D

± 0.01 mm

Fig. 7-3 Measuring the diameter of the sintered PTC ring

7. Compare the measured diameter D with the values given in the ring-specific calibration

table: The corresponding table value shows the actual firing temperature.

8. Change the CCF value if the actual firing temperature deviates from the nominal

temperature of 1500 °C.

Loading...

Loading...