Tape pulled from or broken near leader pin

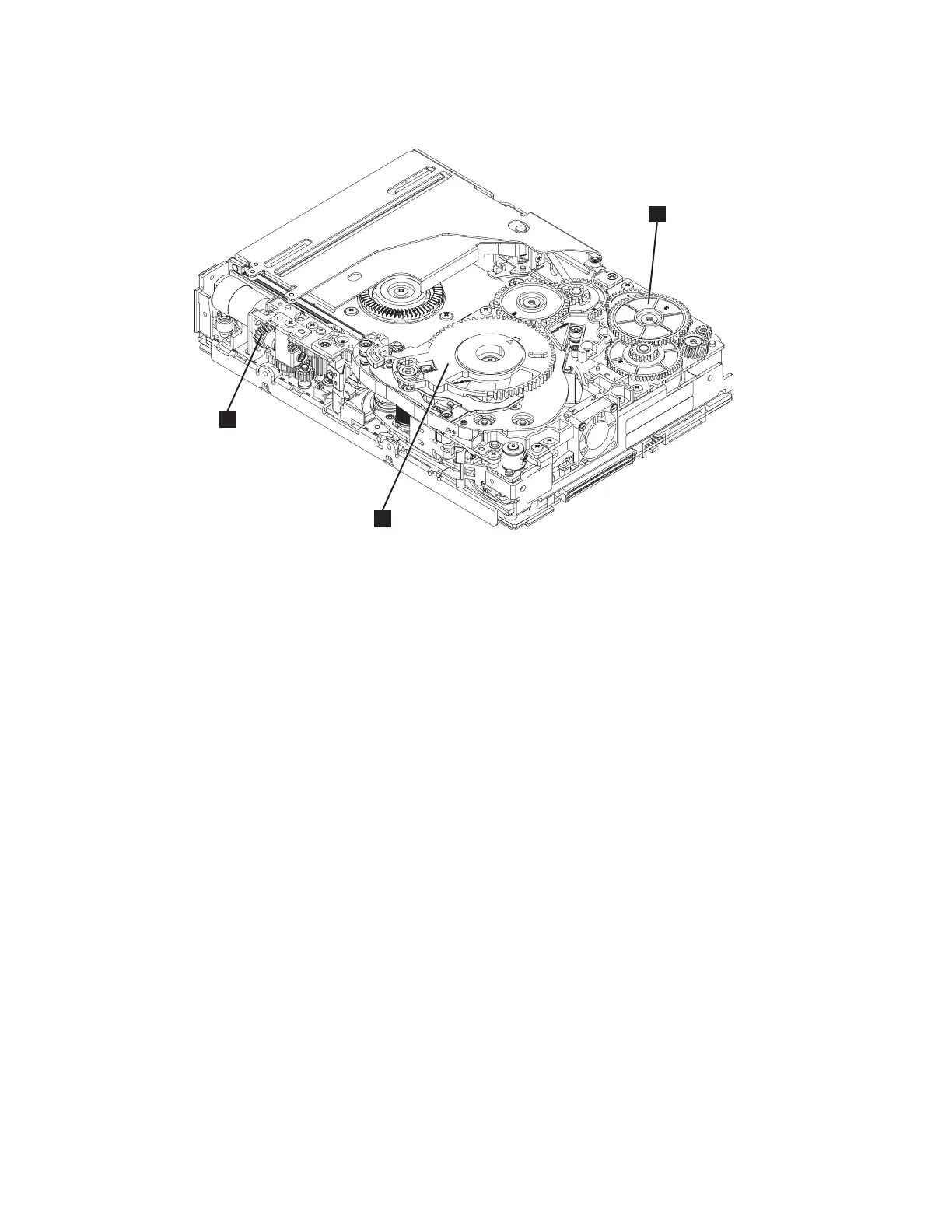

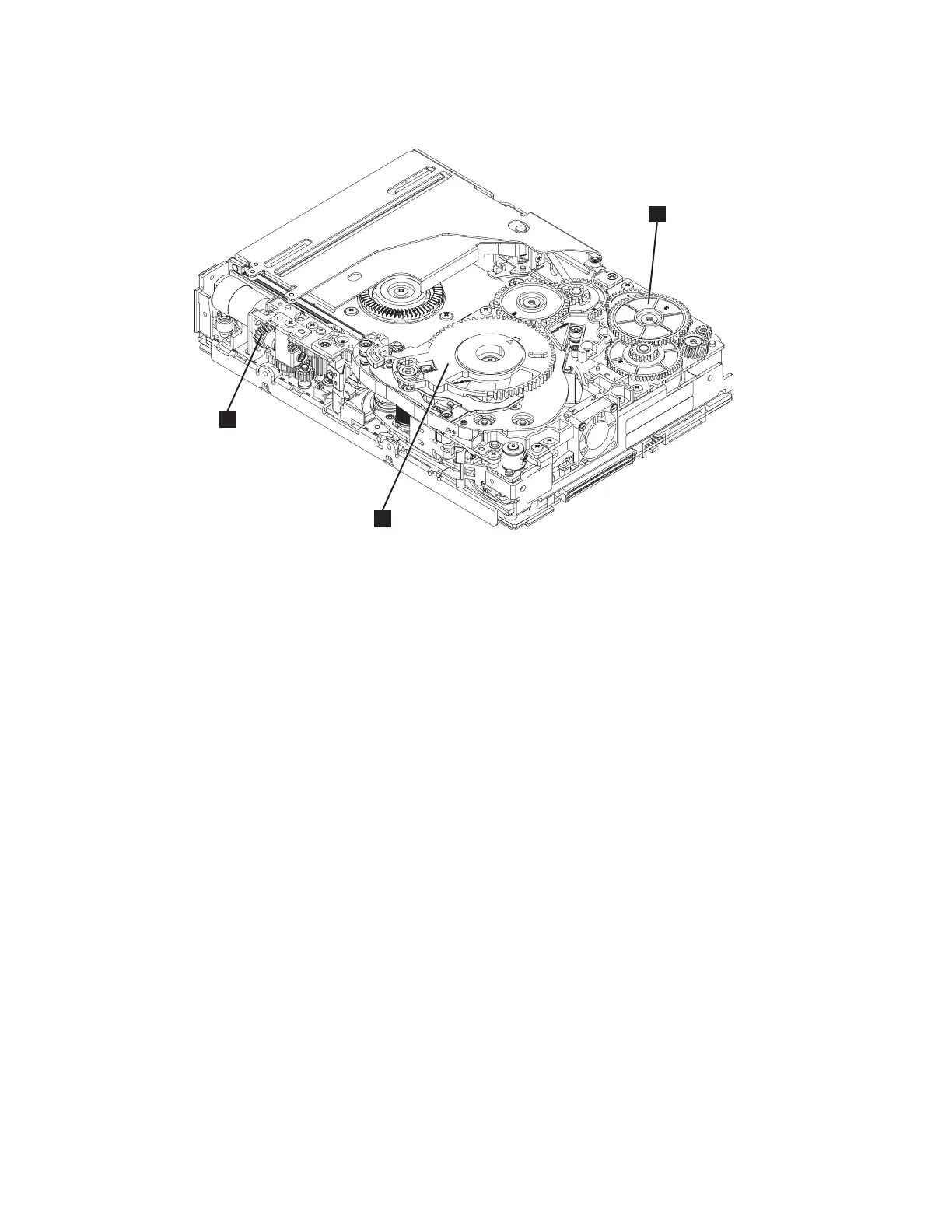

▌1▐ Threader intermediate gear ▌3▐ Loader motor worm gear

▌2▐ Threader mechanism gear

1. Pull out tape from the takeup reel.

Note: If there is more than approximately 0.6 m (2 ft.) of tape on the takeup reel, go to “Tape broken

in mid-tape” on page 181.

2. If there is less than approximately 0.6 m (2 ft.) of tape on the takeup reel, cut off the excess tape as

close to the leader pin as possible.

3. Reattach the leader pin to the remaining tape.

4. Locate the threader intermediate gear (▌1▐ in Figure 174) near the rear of the drive. You can use your

finger to rotate the threader intermediate gear (▌1▐ in Figure 174) and slowly rotate the threader

mechanism gear (▌2▐ inFigure 174) clockwise. This procedure draws the tape leader block assembly

(LBA) into the cartridge.

5. As the leader pin is secured in the cartridge, the leader pin retention spring clips click into place. If

you do not hear the click, continue rolling until the threader intermediate gear (▌1▐ in Figure 174)

stops. The LBA is in the correct position.

Note: Be sure to keep tension on the tape as the LBA is drawn into the cartridge.

6. Rotate the loader motor worm gear (▌3▐ in Figure 174 and ▌1▐ in Figure 175 on page 181) clockwise

as viewed from the front of the drive until it stops. This procedure releases the LBA leader pin.

7. Rotate the threader intermediate gear (▌1▐ in Figure 174) counterclockwise until the leader block is in

front of the read/write head. This procedure moves the LBA out of the cartridge.

Figure 174. Drive with cover removed to reveal gear train

180 IBM TS2900 Tape Autoloader: Setup, Operator, and Service Guide Machine Type 3572

Loading...

Loading...