SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3-74 – JLG Lift – 3121642

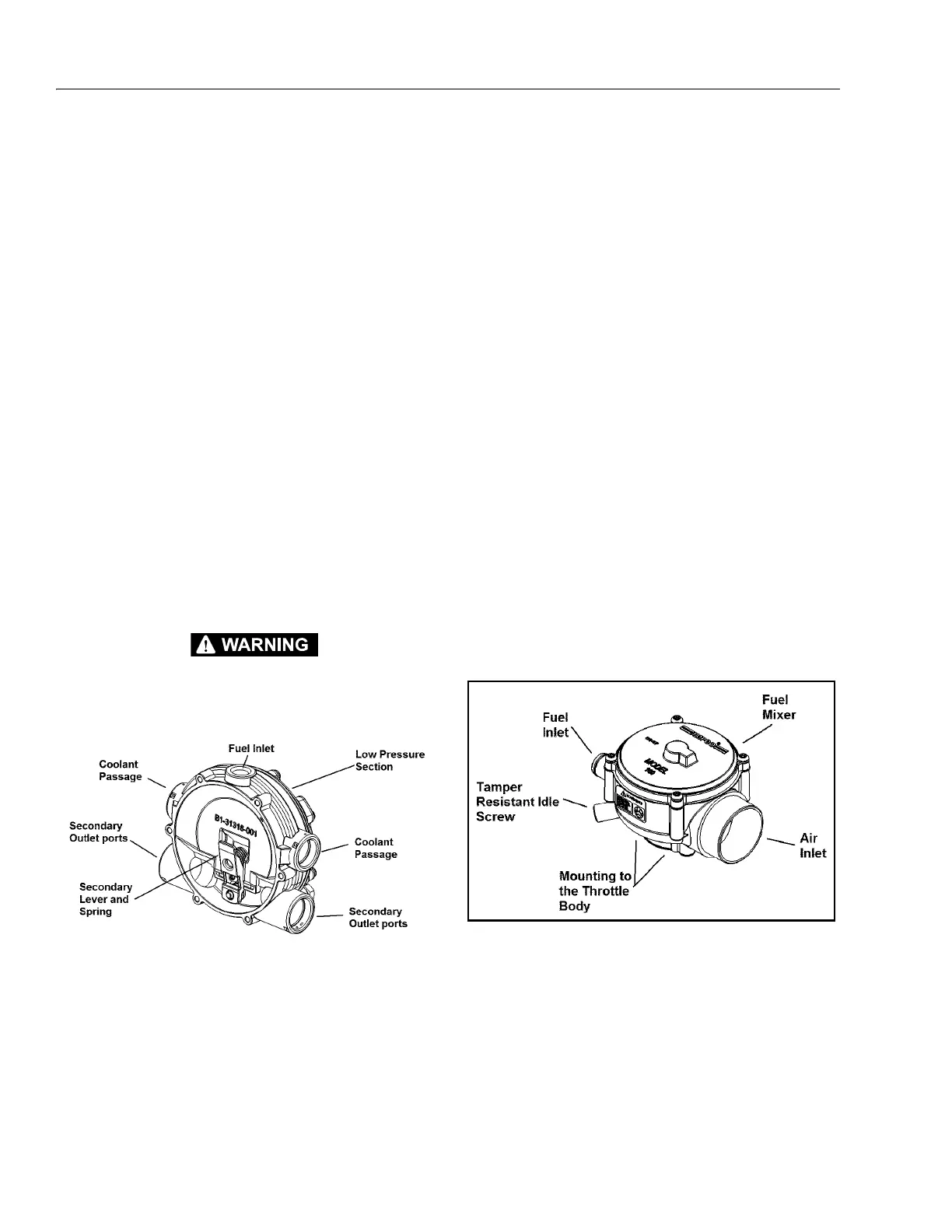

Low Pressure Regulator (LPR)

The LPR is a combination vaporizer, pressure regulating

device. The LPR is a negative pressure, two stage regulator that

is normally closed when the engine is not running. When the

engine is cranking or running, a partial vacuum is created in

the fuel line which connects the regulator to the mixer. This

partial vacuum opens the regulator permitting fuel to flow to

the mixer.

Propane fuel enters the primary port of the LPR and passes

through the primary jet and into the primary/ exchanger

chamber. As the propane passes through the heat exchanger,

the fuel expands and creates pressure inside the chamber. The

pressure rises as the fuel expands. When the pressure rises

above 1.5 psi (0.103 bar), sufficient pressure is exerted on the

primary diaphragm to cause the diaphragm plate to pivot and

press against the primary valve pin, thus closing off the flow of

fuel. This action causes the flow of fuel into the regulator to be

regulated.

When the engine is cranking, sufficient vacuum will be intro-

duced into the secondary chamber from the mixer drawing

the secondary diaphragm down onto the spring loaded lever

and opening the secondary valve allowing vaporized fuel to

pass to the mixer. This mechanical action, in conjunction with

the EPR reactions, causes the downward action on the second-

ary lever, causing it to open wider allowing more fuel to flow

to the mixer.

THE VOICE COIL SECTION OF THE EPR ASSEMBLY IS AN EMISSIONS CONTROL

DEVICE AND CANNOT BE REBUILT. IF THE COIL ASSEMBLY FAILS TO OPERATE

PROPERLY, REPLACE IT WITH AN OEM REPLACEMENT PART ONLY.

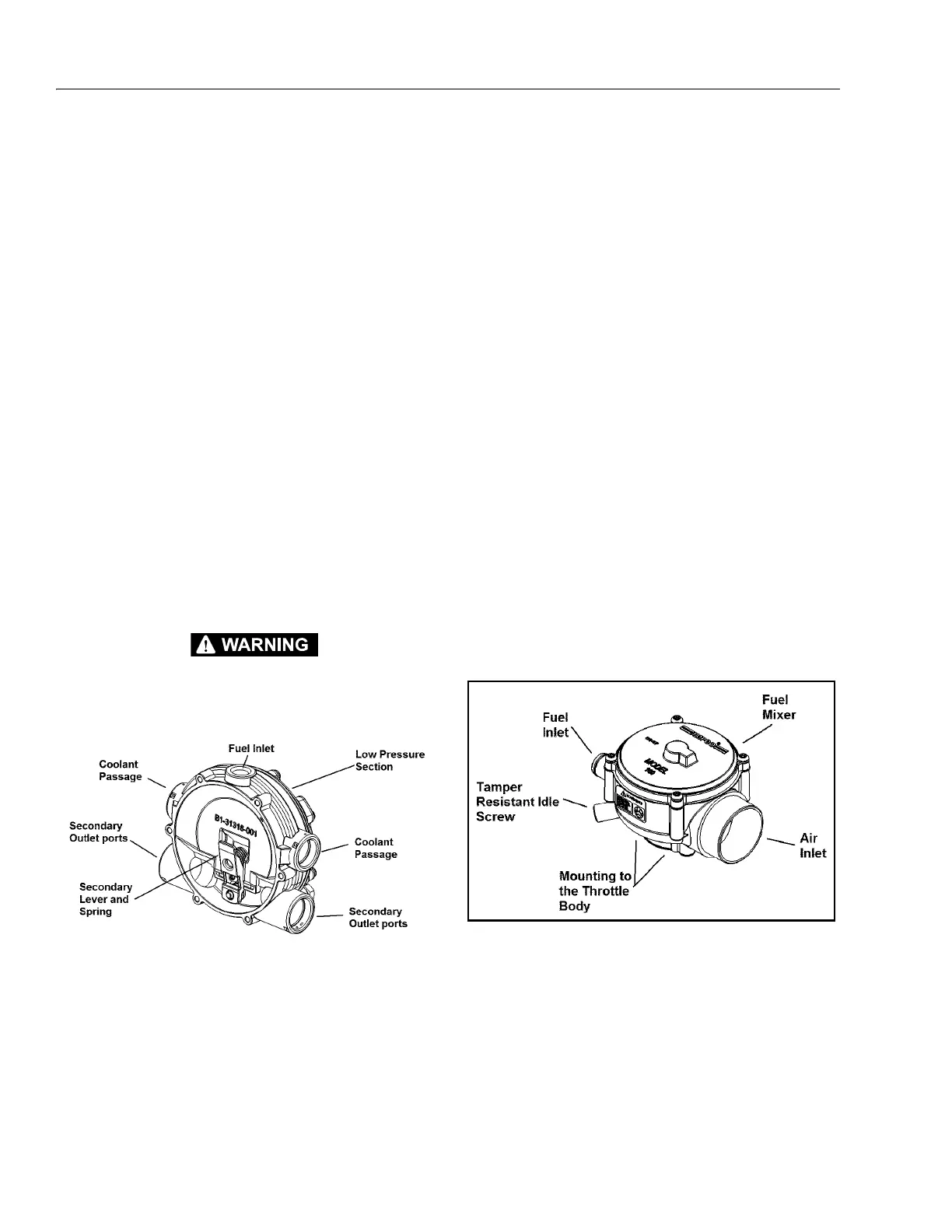

Air Fuel Mixer

The air valve mixer is an air-fuel metering device and is com-

pletely self-contained. The mixer is an air valve design, utiliz-

ing a relatively constant pressure drop to draw fuel into the

mixer from cranking to full load. The mixer is mounted in the

air stream ahead of the throttle control device.

When the engine begins to crank, (it draws in air with the air

valve covering the inlet) negative pressure begins to build.

This negative pressure signal is communicated to the top of

the air valve chamber through 4 vacuum ports in the air valve

assembly. A pressure/force imbalance begins to build across

the air valve diaphragm between the air valve vacuum cham-

ber and the atmospheric pressure below the diaphragm. The

air valve vacuum spring is calibrated to generate from 4.0

inches (101.6 mm) of water column at start to as high as 14.0

inches (355.60 mm) of water column at full throttle. The vac-

uum being created is referred to as Air Valve Vacuum (AVV). As

the air valve vacuum reaches 4.0 inches (101.6 mm) of water

column, the air valve begins to lift against the air valve spring.

The amount of AVV generated is a direct result of the throttle

position. At low engine speed, the air valve vacuum is low and

the air valve position is low, thus creating a small venturi for

the fuel to flow. As the engine speed increases, the AVV

increases and the air valve is lifted higher, thus creating a

much larger venturi. This AVV is communicated from the mixer

venture to the LPR secondary chamber via the low pressure

fuel supply hose. As the AVV increases in the secondary cham-

ber, the secondary diaphragm is drawn further down, forcing

the secondary valve lever to open wider.

Figure 3-81. Low Pressure Regulators

Figure 3-82. Air Fuel Mixer

Loading...

Loading...