SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3121642 – JLG Lift – 3-27

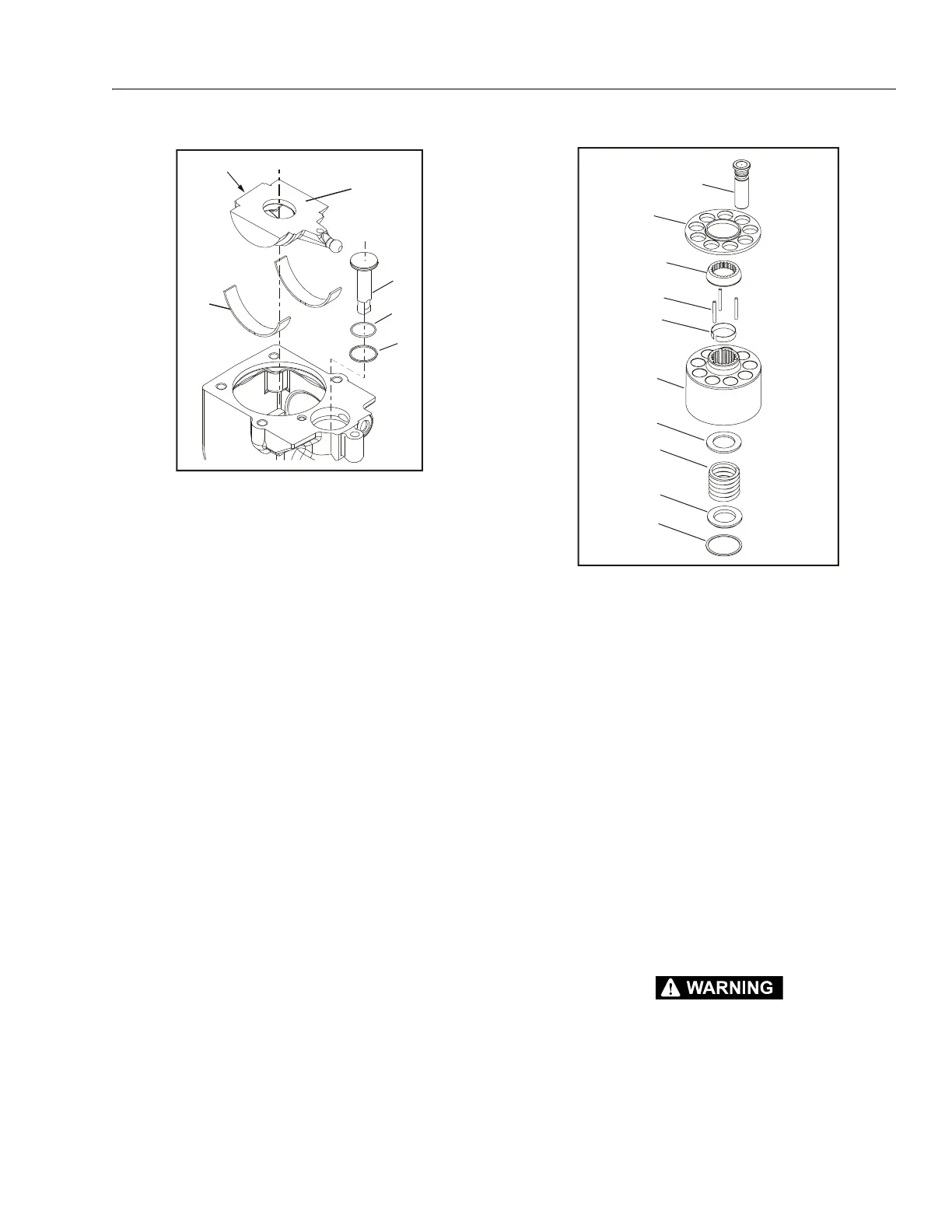

23. Turn housing over and remove the swashplate (39) by

lifting on the end opposite the servo lever.

24. Remove the servo piston (40). Remove the piston seal

(41) and O-ring (42) from the servo piston. Discard the

seal and O-ring.

25. Remove the journal bearings (43) from the housing. If

the bearings are to be reused, note the location and ori-

entation of each bearing for reassembly.

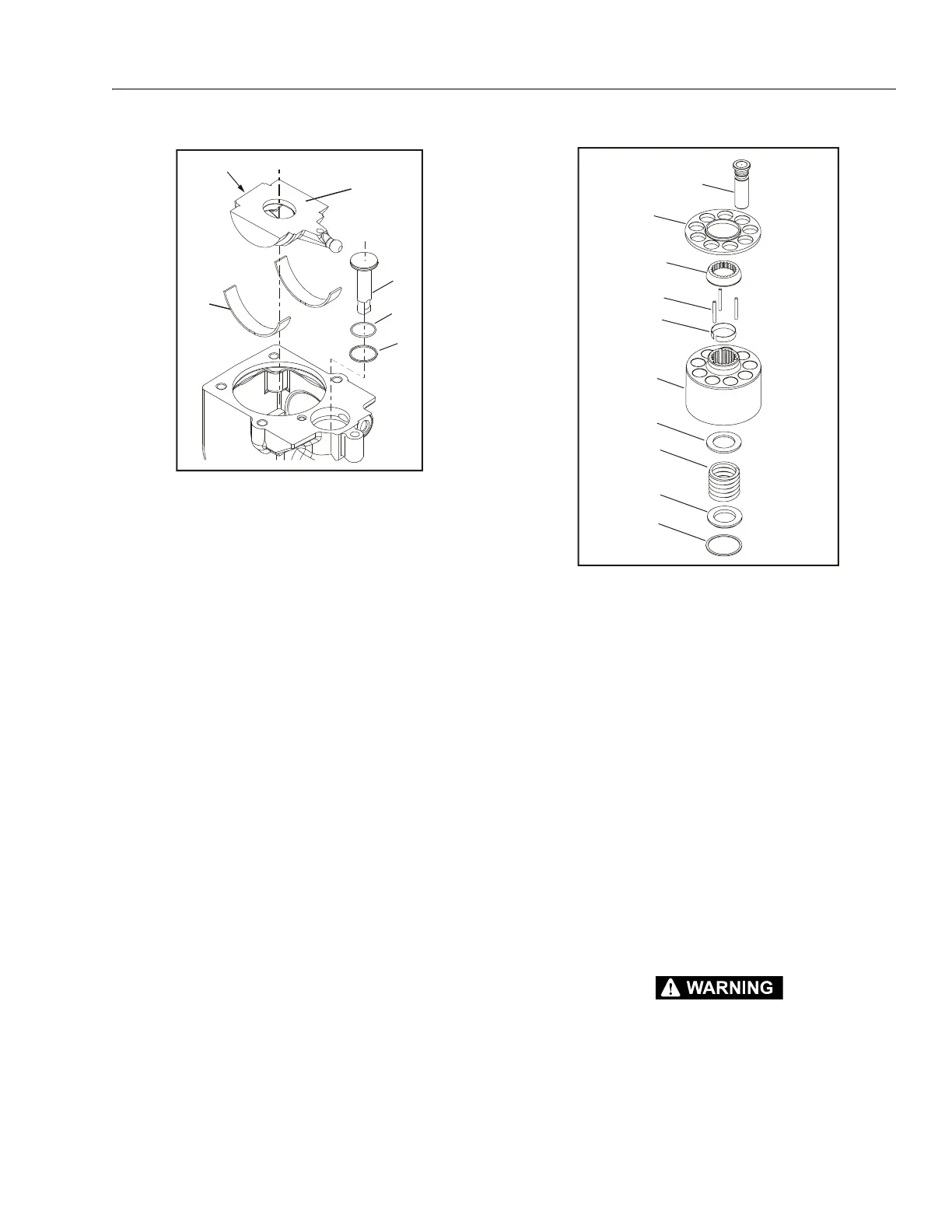

26. Remove pistons (44) and slipper retainer (45) from the

cylinder block (46).

The pistons are not selectively fitted, however units with

high hourly usage may develop wear patterns. Number

the pistons and bores for reassembly if they are to be

reused.

27. Remove the ball guide (47), hold-down pins (48), and

retaining ring (49) from the cylinder block.

NOTE: Most repairs do not require block spring removal. Perform

this procedure only if you suspect problems with the block

spring.

RISK OF PERSONAL INJURY: COMPRESSING THE BLOCK SPRING REQUIRES

FORCE OF ABOUT 80 TO 90 LBF (350 TO 400 N). USE A PRESS SUFFICIENT TO

MAINTAIN THIS FORCE WITH REASONABLE EFFORT. ENSURE THE SPRING IS

SECURE BEFORE ATTEMPTING TO REMOVE THE SPIRAL RETAINING RING.

RELEASE THE PRESSURE SLOWLY AFTER THE RETAINING RING IS REMOVED.

39. Swashplate

40. Servo Piston

41. Piston Seal

42. O-ring

43. Journal Bearings

Figure 3-15. Swash Plate & Servo Piston

44. Piston

45. Slipper Retainer

46. Cylinder Block

47. Ball Guide

48. Holddown Pins

49. Retaining Ring

50. Block Spring Washer

51. Spiral Retaining Ring

52. Block Spring

53. Inner Block Spring Washer

Figure 3-16. Cylinder Kit Disassembly

Loading...

Loading...