SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3-10 – JLG Lift – 3121642

10. At this point the hub-spindle disassembly is complete.

Cover Disassembly

1. Remove the two bolts (6C) holding disconnect cap (6D)

to cover (6A).

2. Remove disconnect cap (6D) from top of cover cap (6B)

and cover (6A).

3. Remove the two bolts (6C) attaching cover cap (6B) to

cover (6A).

4. Remove cover cap (6B) from cover (6A).

5. Remove disconnect rod (6K) from cover cap (6B).

6. Pry o-ring (6F) out of the groove inside cover cap (6B).

Discard the o-ring.

7. Remove o-ring (6G) from the flange of cover cap (6B).

Discard the o-ring.

8. Remove pipe plug (6H) from cover (6A).

9. At this point the cover disassembly is complete.

Carrier Disassembly

NOTE: When removing the needle rollers from the cluster gears,

discard the old needle rollers and use new ones during re-

assembly.

1. Using a punch and hammer, drive roll pin (3G) into

planet shaft (3E).

NOTE: Be sure to drive the roll pin all the way into the planet shaft.

Failure to do so could result in damage to the carrier when

removing the planet shaft from the carrier.

2. Using a punch and hammer, drive the planet shaft (3E)

out of the planet shaft hole in the carrier housing (3A).

3. When removing the planet shaft (3E) from the carrier

housing, one thrust washer (38), one cluster gear (3F),

and one more thrust washer will come off of the planet

shaft and come to rest inside the carrier. Remove these

parts from inside the carrier.

4. Remove 16 needle rollers (3C) from inside one end of

cluster gear (3F). Discard the needle rollers.

5. Remove one spacer (3D) from inside cluster gear (3F).

6. Remove the remaining 16 needle rollers (3C) from the

other side of cluster gear (3F). Discard the needle rollers.

7. Repeat steps 1-6 to remove and disassemble the two

remaining cluster gears.

8. At this point the carrier disassembly is complete.

Assembly of the Carrier

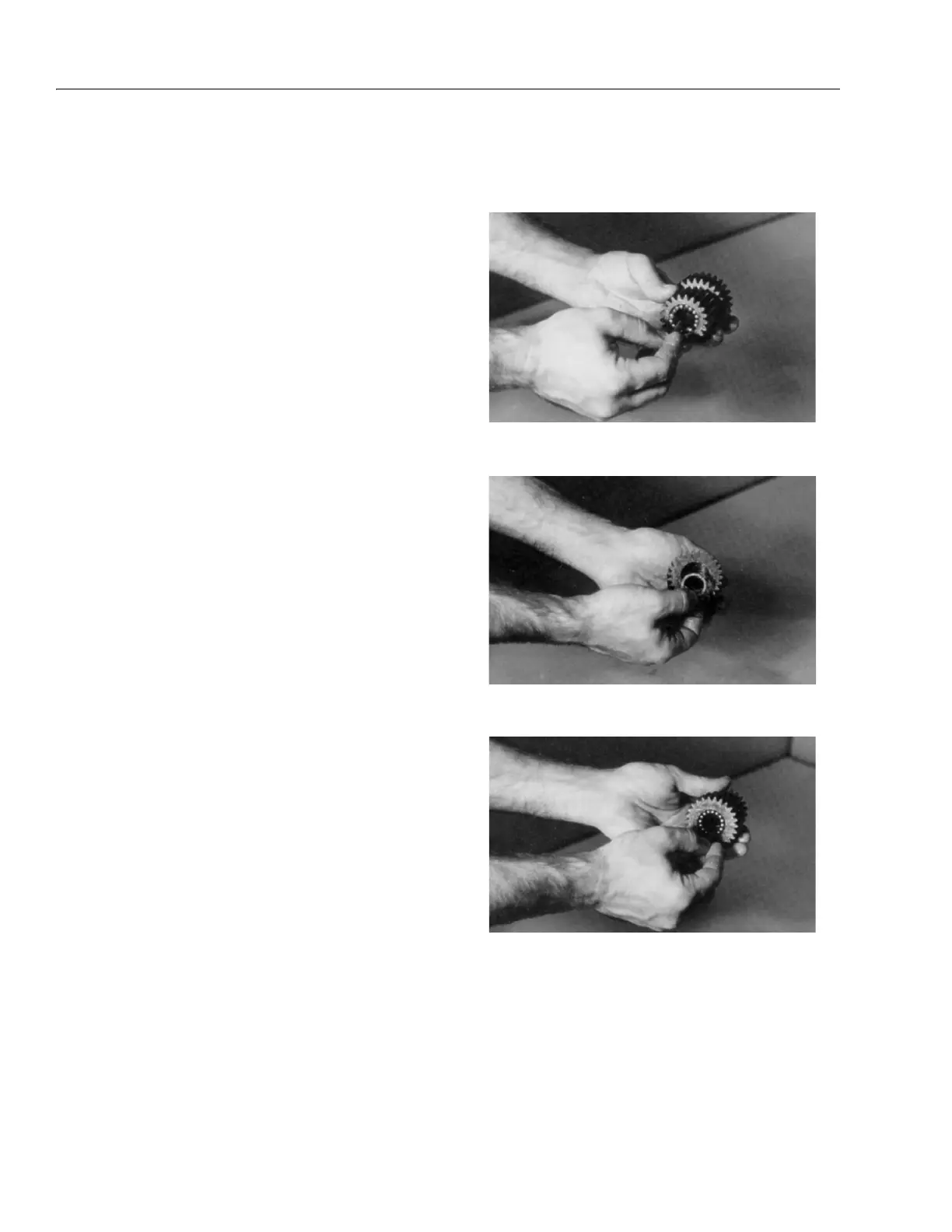

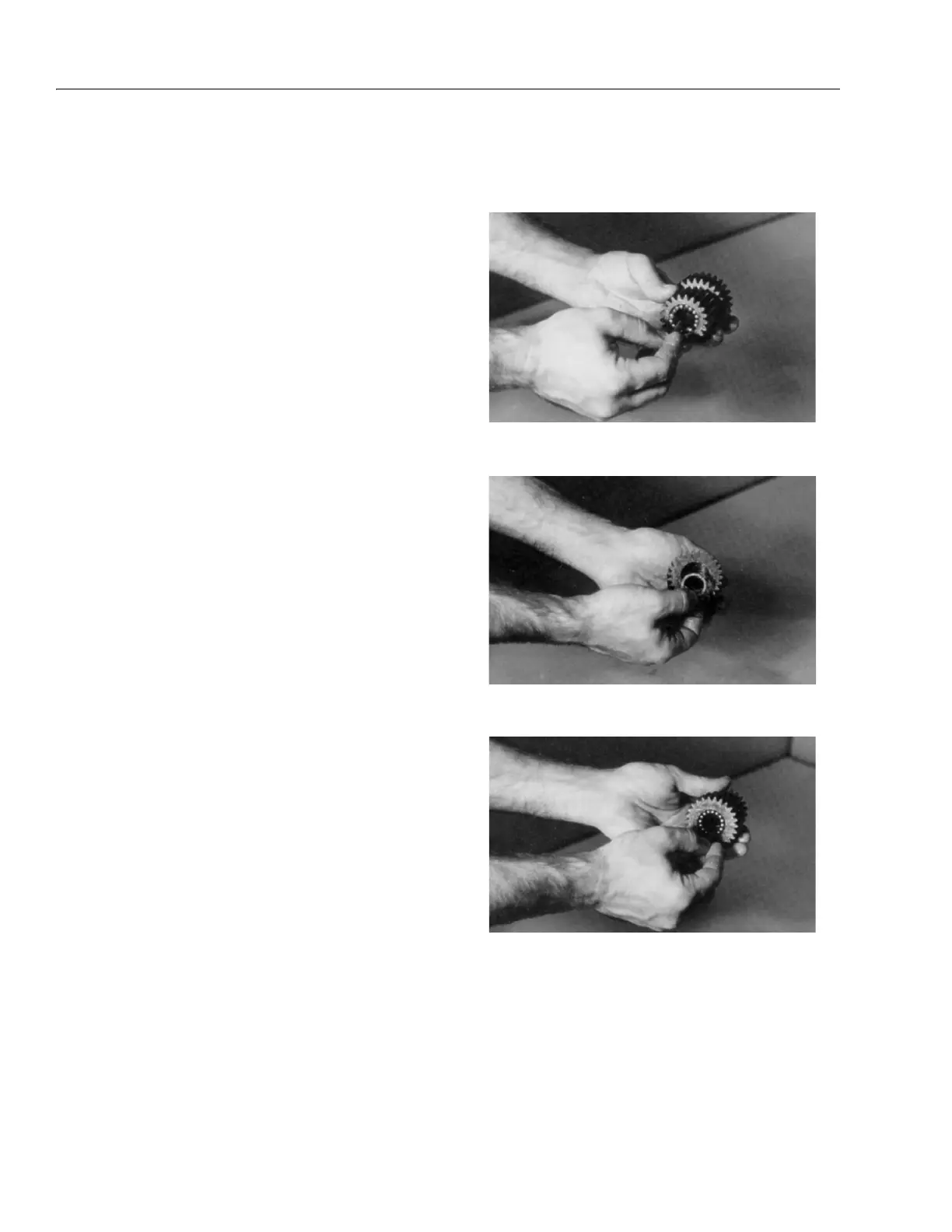

1. Apply grease to the inside of one cluster gear (3F) and

line one half of cluster gear with 16 needle rollers (3C).

2. Place one spacer (3D) inside cluster gear (3F) so that it

rests on top of the needle rollers.

3. Line the remaining half of cluster gear (3F) with 16 nee-

dle rollers.

Loading...

Loading...