SECTION 4 - HYDRAULICS

3121642 – JLG Lift – 4-11

pump remains in neutral. With the engine at normal operating

RPM, slowly check for forward and reverse machine operation.

Charge pressure may slightly decrease during forward or

reverse operation. Continue to cycle slowly between forward

and reverse for at least five minutes.

Shut down engine, remove gauges, and plug ports. Check res-

ervoir level and add filtered fluid if needed.

The machine is now ready for operation.

4.8 HYDRAULIC GEAR PUMP

Overhaul pump only in a clean, dust free location, using clean

tools and equipment. dirt and grit will damage the highly

machined surfaces and will result in leakage or premature fail-

ure of the pump.

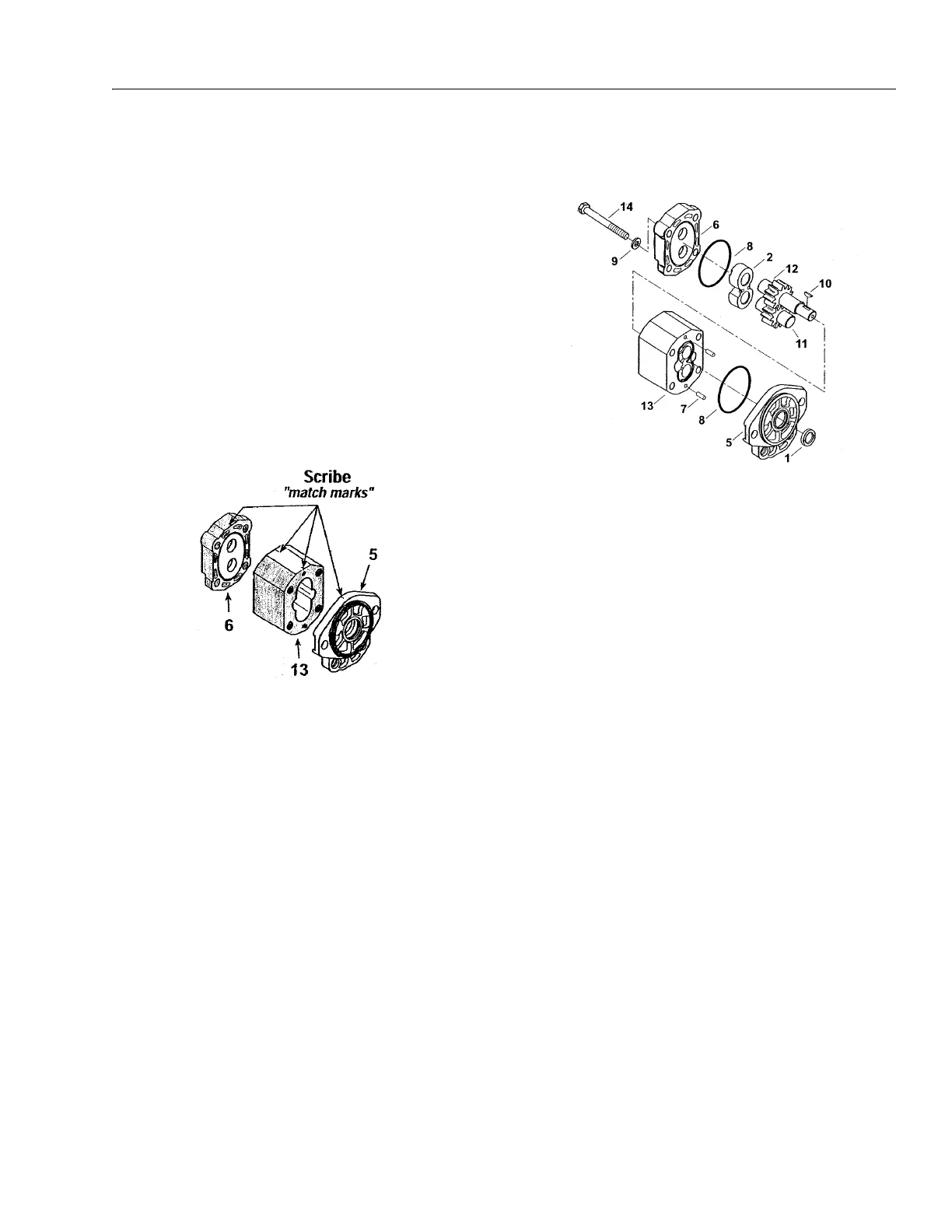

Before beginning disassembly, scribe "match marks" on the

body (13) and covers (5 and 6) to ensure that the pump will be

reassembled in the same manner as it was shipped from the

factory. If the body or rear cover is replaced during overhaul,

scribe a match mark on the new part in the same location as

on the part it replaced.

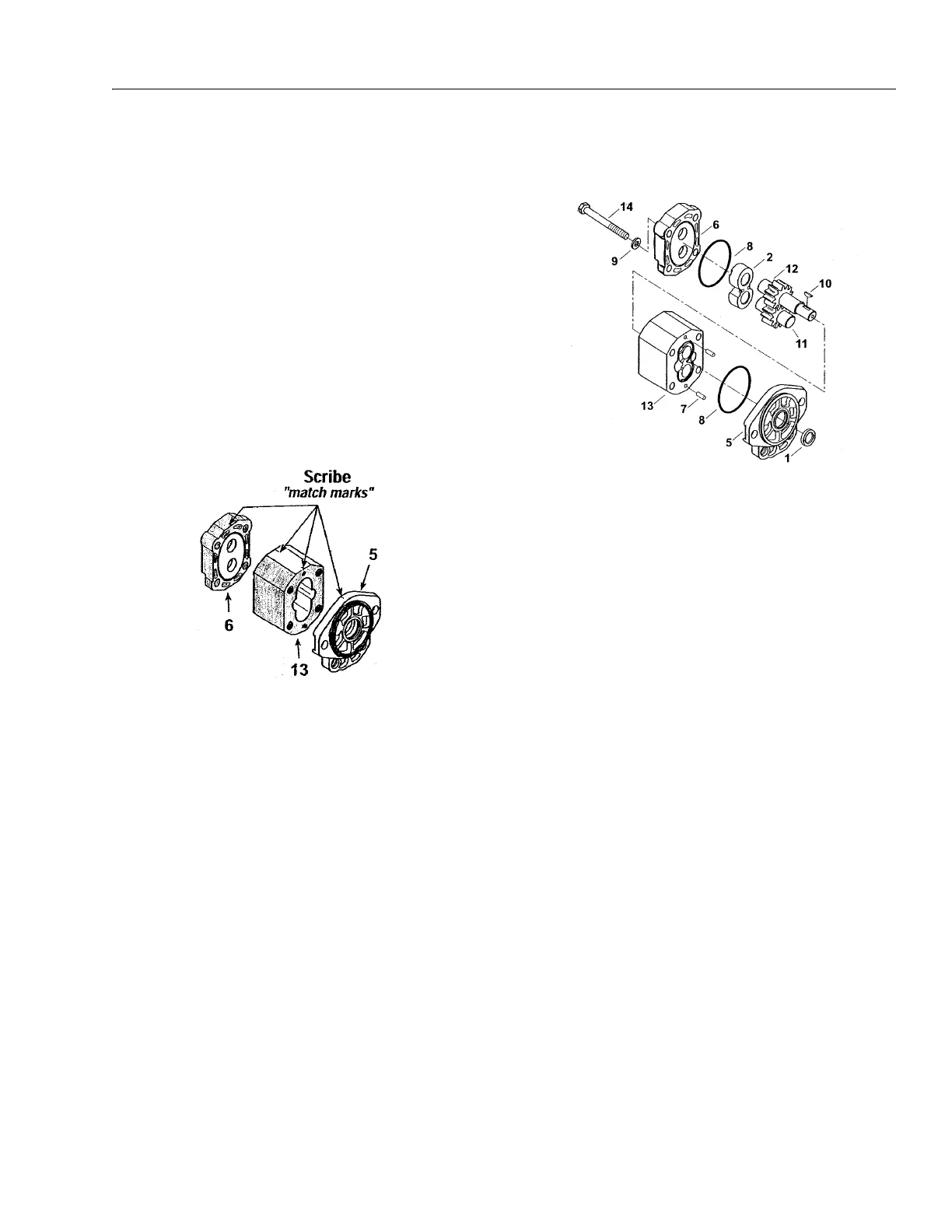

Pump Disassembly

1. Clean outside of pump with a good grade solvent and

dry thoroughly.

2. On models with a splined drive shaft, proceed to step 3.

On models with a keyed drive shaft, remove drive key

(10) from drive shaft. Using a file or stone, remove burrs

from shaft end of keyway.

3. Using light clamping pressure on the ears of the front

cover, secure unit in vise with shaft side down. Remove

the cap screws (14) and washers (9).

4. Separate rear cover (6) from the body (13). The static seal

(8) may remain either with the body or the cover. In

either case, remove the static seal and discard.

5. Lift out the rear bearing block (2), drive gear (12), and

driven gear (11).

6. Separate body (13) from front cover (5). Dowel pins (7)

and the front static seal (8) may remain with either the

body (13) or the front cover (5). In either case, remove

the static seal and discard.

7. The front bearing block (2) will typically remain in the

body (13). Invert the body and lift out the bearing block.

8. Invert front cover (5) with shaft seal up. Remove the

shaft seal (1) by prying it out with a large screwdriver.

NOTE: During disassembly, take special note of the wear patterns

on the bearing blocks (2) and body (13). Relate these pat-

terns to the inlet and outlet sides of the pump. The large

port ,whether in the body (13) or the rear cover (6), corre-

sponds to the inlet side of the pump. The inlet side of the

body can be identified by the gear contact pattern in the

gear bore. The bearing block will have somewhat heavier

wear patterns on the inlet side.

Parts Inspection

1. Wash all parts and dry thoroughly.

2. Inspect front and rear bearing block. Replace if scoring

or uneven wear is observed.

Loading...

Loading...