SECTION 4 - HYDRAULICS

4-28 – JLG Lift – 3121642

8. Reconnect electrical connections and test the pump for

proper operation.

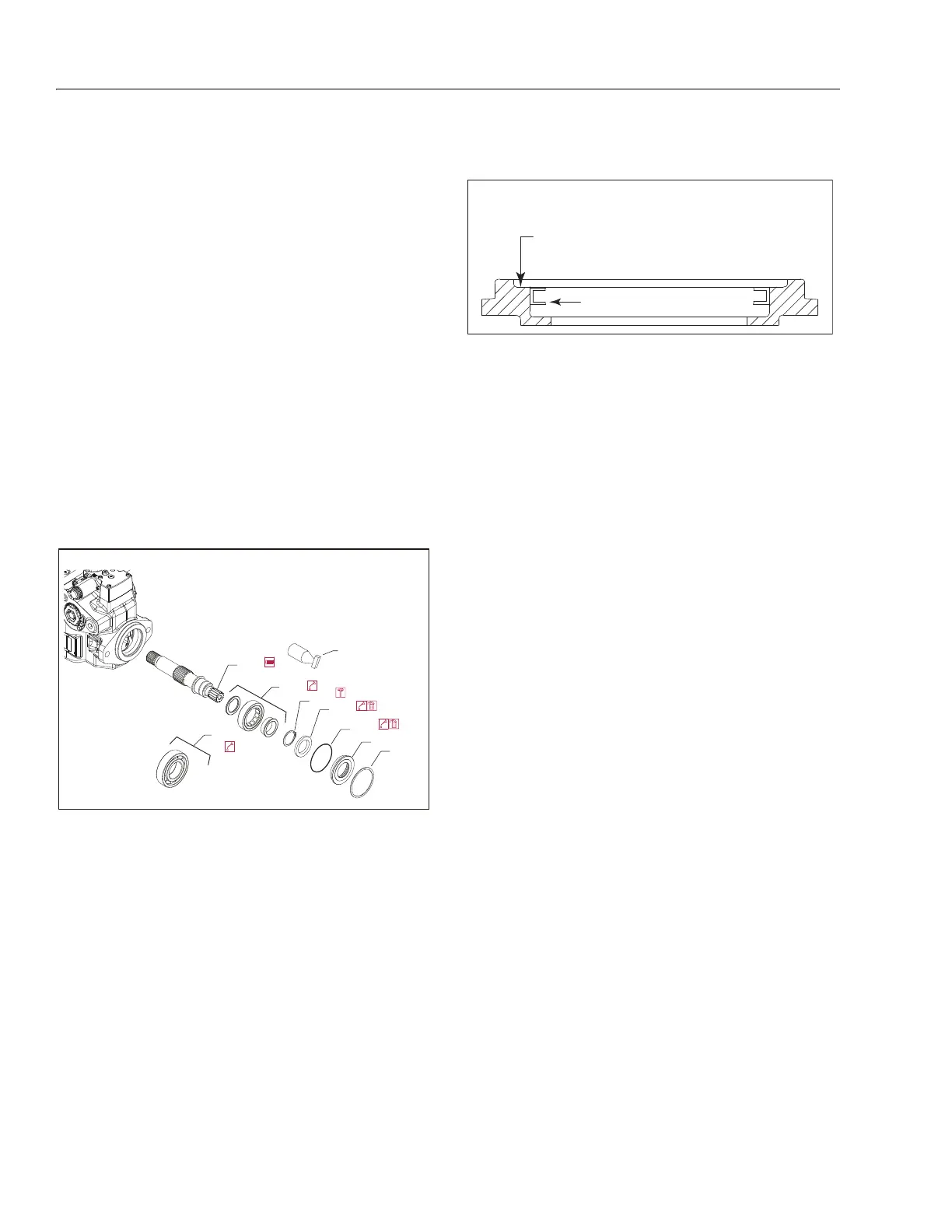

Shaft Seal, Roller Bearing & Shaft Replacement

NOTE: The shaft assembly is serviceable without disassembling

the pump. Orient the pump on the work surface so the

shaft is pointing to the side.

REMOVAL:

1. Unwind the spiral ring (J300) from the housing to

release the shaft/seal/bearing subassembly.

2. Pry on the lip of the seal carrier (J275) to dislodge it from

the pump. Remove the seal carrier. Remove and discard

O-ring (J260). Press the seal (J250) out of the carrier and

discard.

3. Pull the shaft (J100) with bearing (J150) out of the

pump. If necessary, tap lightly on the shaft to dislodge it

from the cylinder block.

4. Remove the retaining ring (J200) using retaining ring

pliers. Press the bearing off the shaft.

INSPECTION:

5. Inspect the shaft journals for wear, scratching, and pits.

Check the splines for fretting; replace if damaged.

Rotate the bearing, if it does not rotate smoothly,

replace it.

REASSEMBLY:

6. Press the bearing (J150) onto the shaft (J100) and

replace the retaining ring (J200). Ensure the retaining

ring diameter is less than 1.53 in (38.84 mm) when

installed on the shaft.

7. Install the shaft/bearing assembly into the pump.

8. Lubricate and install a new O-ring (J260) onto seal car-

rier (J275). Press a new seal (J250) into the seal carrier.

Press the seal until it is flush within 0.005 in (+0.12mm )

or 0.0028 in (-0.72 mm) of the inside lip of the carrier: see

illustration.

9. Cover the shaft with a protective sleeve while installing

the seal carrier. Hand press the seal carrier into the hous-

ing. Ensure the seal carrier clears the spiral ring groove

in the housing. Remove the protective sleeve.

10. Wind the spiral ring into the housing. Ensure the inside

diameter of the spiral ring is greater than 2.677 in (68

mm) after installation.

Charge Pump

If the pump has an auxiliary pump attached, remove the auxil-

iary pump and connecting shaft before removing the auxiliary

pad.

REMOVAL:

1. Position pump so end cover or auxiliary pad is on top.

2. If necessary, remove auxiliary pump (not shown), or

shipping cover (K300) and pad seal (K250) as shown on

following page.

3. Remove end cover/auxiliary pad screws (K400) using a

10 mm internal hex wrench.

NOTE: Alignment pins (G450) are in end cover. They may dislodge

during disassembly.

4. Remove and discard gasket (K150).

5. Remove thrust washer (K500). Note thrust washer orien-

tation.

6. Use a small hook to remove pressure balance plate

(S200) and seal (S300). Note plate orientation. Discard

seal.

7. Remove coupling (K200). Use a small hook if necessary.

8. Remove the charge pump outer ring (S150), and gearset

(S100).

9. Remove valve plate (S250) with seal (S300). Discard seal

INSPECTION:

10. Inspect the components for wear, scratches or pitting.

Carefully inspect the valve and pressure-balance plates.

Scratches on these components will cause a loss of

Shaft assembly

J150

J100

J200

J250

J260

J275

J300

J150

Protective

sleeve

Seal

Press flush to this surface

0.005 in +0.12 mm) 0.028 in -0.72 mm) ( / (

Positioning seal in seal carrier

Loading...

Loading...