SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3121642 – JLG Lift – 3-83

3.19 GM ENGINE LPG FUEL SYSTEM DIAGNOSIS

Fuel System Description

To maintain fuel and emission control on the LPG fuel system,

the Engine Control Unit (ECM) relies on numerous engine sen-

sor and output data from the Electronic Pressure Regulator

(EPR). The ECM will then determine the target fuel calibration

and command the EPR to reposition the voice coil to the

proper position which, subsequently repositions the second-

ary lever in the pressure regulator to maintain proper control.

The EPR and ECM will continue to communicate back and

forth during normal operation.

In the event that the EPR fails to communicate or the Commu-

nications Area Network (CAN) cable fails to transmit data, the

regulator will operate in an open loop configuration. As the air

valve vacuum in the mixer venturi is communicated to the sec-

ondary chamber of the regulator, the secondary diaphragm

will be drawn in a downwards motion. This downward motion

will cause the secondary lever to open, thus allowing more

fuel to enter the mixer.

In the (LPR), the fuel is vaporized and the pressure reduced in

two stages. The first stage reduces the pressure to approxi-

mately 1.0 to 3.0 psi (6.8 to 20.6 kPa). The second stage

reduces the pressure to approximately negative 1.5" of water

column.

The fuel is then drawn from the secondary chamber of the LPR

by the vacuum generated by air flowing through the mixer.

This vacuum signal is also used to generate lift for the mixer air

valve. This vacuum signal is most commonly referred to as air

valve vacuum. In the mixer, the fuel mixes with the air entering

the engine. This air/fuel mixture is then drawn into the engine

for combustion.

Diagnostic Aids

This procedure is intended to diagnose a vehicle operating on

LPG. If the vehicle will not continue to run on LPG, refer to

Hard Start for preliminary checks. Before proceeding with this

procedure, verify that the vehicle has a sufficient quantity of

fuel and that liquid fuel is being delivered to the LPR. Also,

ensure that the manual shut off valve on the LPG tank is fully

opened and that the excess flow valve has not been activated.

Tools Required:

• 7/16 Open end wrench (for test port plugs)

• DVOM (GM J 39200, Fluke 88 or equivalent)

• 12 volt test light

Diagnostic Scan Tool:

• Diagnostic Display tool

Pressure Gauges:

•IMPCO ITK-2 Test kit

• Water Column Gauge / Manometer (GM 7333-6 or equiva-

lent)

• 0-10 PSI Gauge

Test Description:

The numbers below refer to step numbers in Table 3-13, LPF

Fuel System Diagnosis.

5. This step determines if the LPR requires replacement.

6. This step determines if the problems are in the mechanical

side of the Pressure Regulator or the Electronic Voice Coil.

10. This step determines if the Mixer requires replacement.

14. This step determines if the Lock Off requires replacement.

17. This step determines if the Fuel Filter requires replacement.

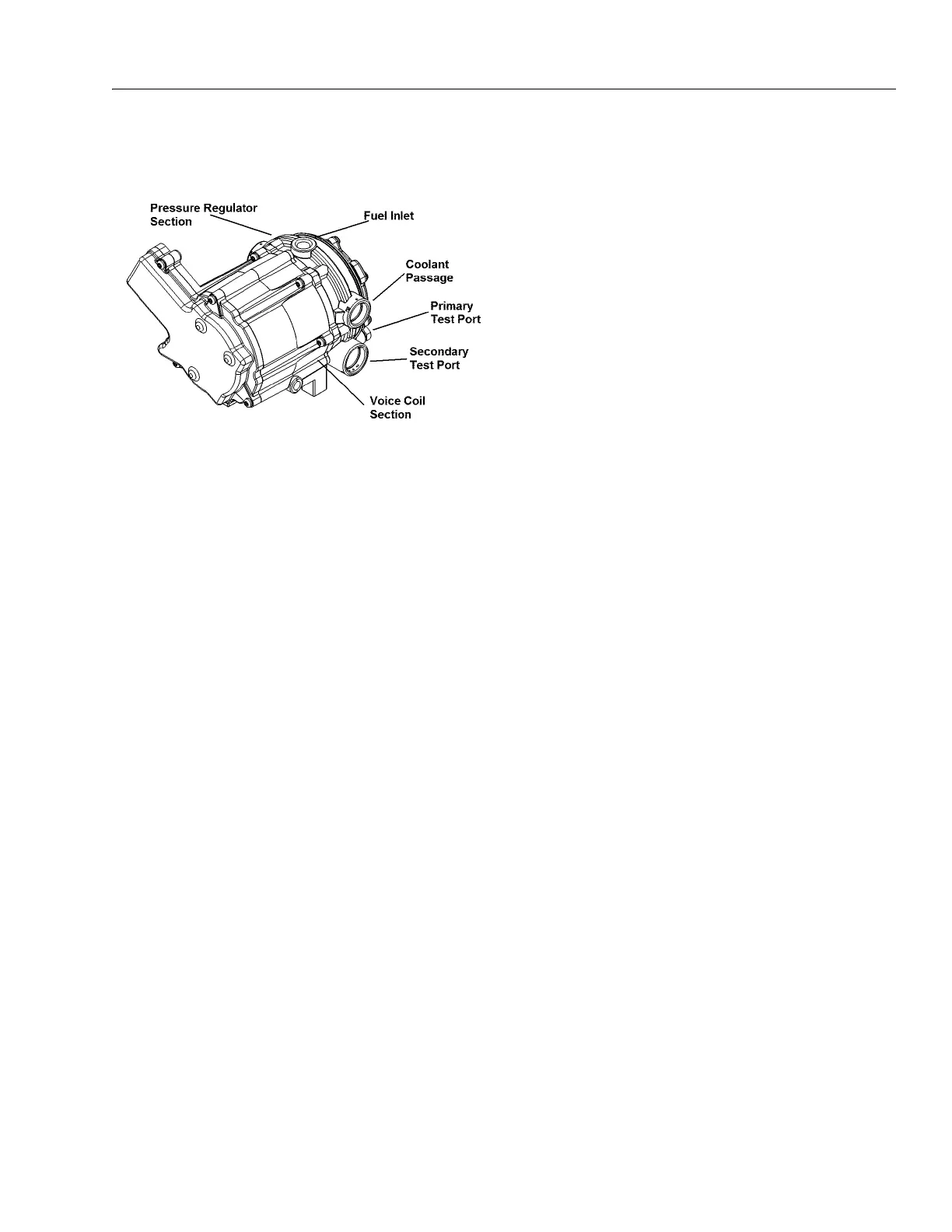

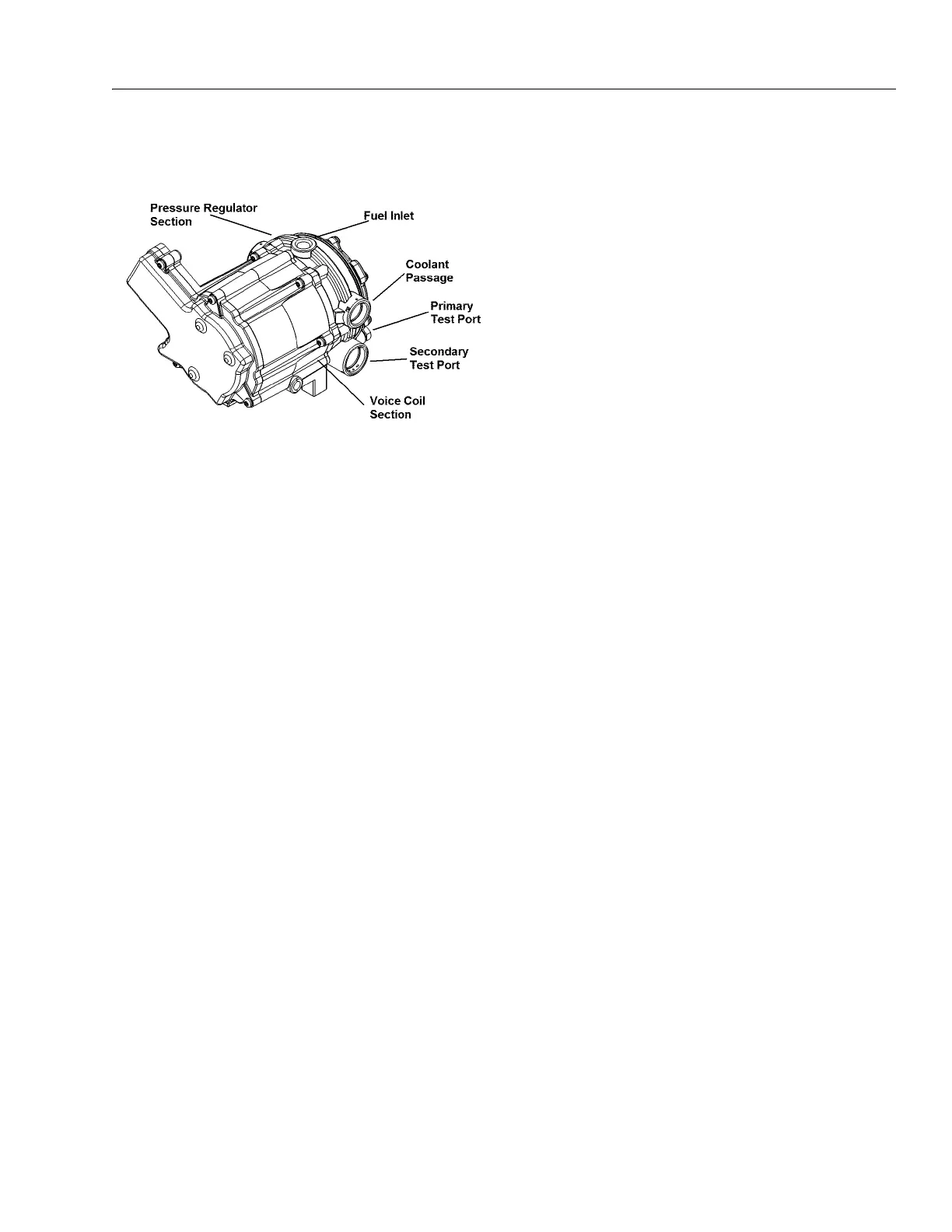

Figure 3-93. EPR Assembly

Loading...

Loading...