SECTION 3 - CHASSIS, PLATFORM & SCISSOR ARMS

3-30 – JLG Lift – 3121642

SERVO PISTON AND MINIMUM ANGLE STOP

Inspect the minimum angle stop, servo piston head, and servo

piston ball-socket for damage or excessive wear. Replace if

necessary.

LOOP FLUSHING SPOOL

Inspect the loop flushing spool. Check for cracks or damage.

Replace if necessary.

Assembly

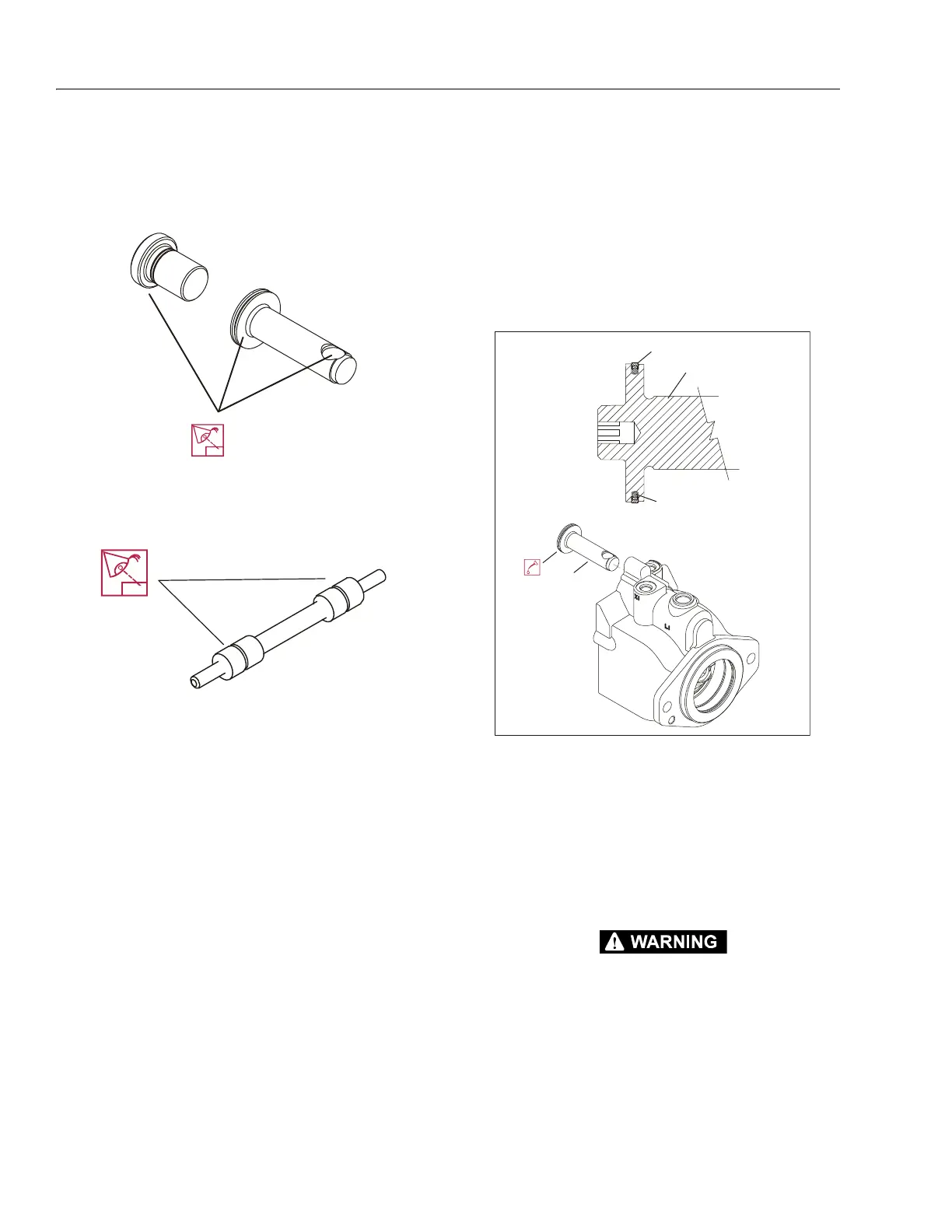

1. Install new O-ring (1) and piston seal (2) to the servo pis-

ton (3). Install the piston seal over the O-ring.

Installing the piston seal stretches it, making it difficult

to install the servo piston in its bore. Allow 30 minutes

for the seal to relax after installation. To speed up seal

relaxation, compress the seal by installing the piston

head into the servo cavity in the end-cap and let it stand

for at least five minutes.

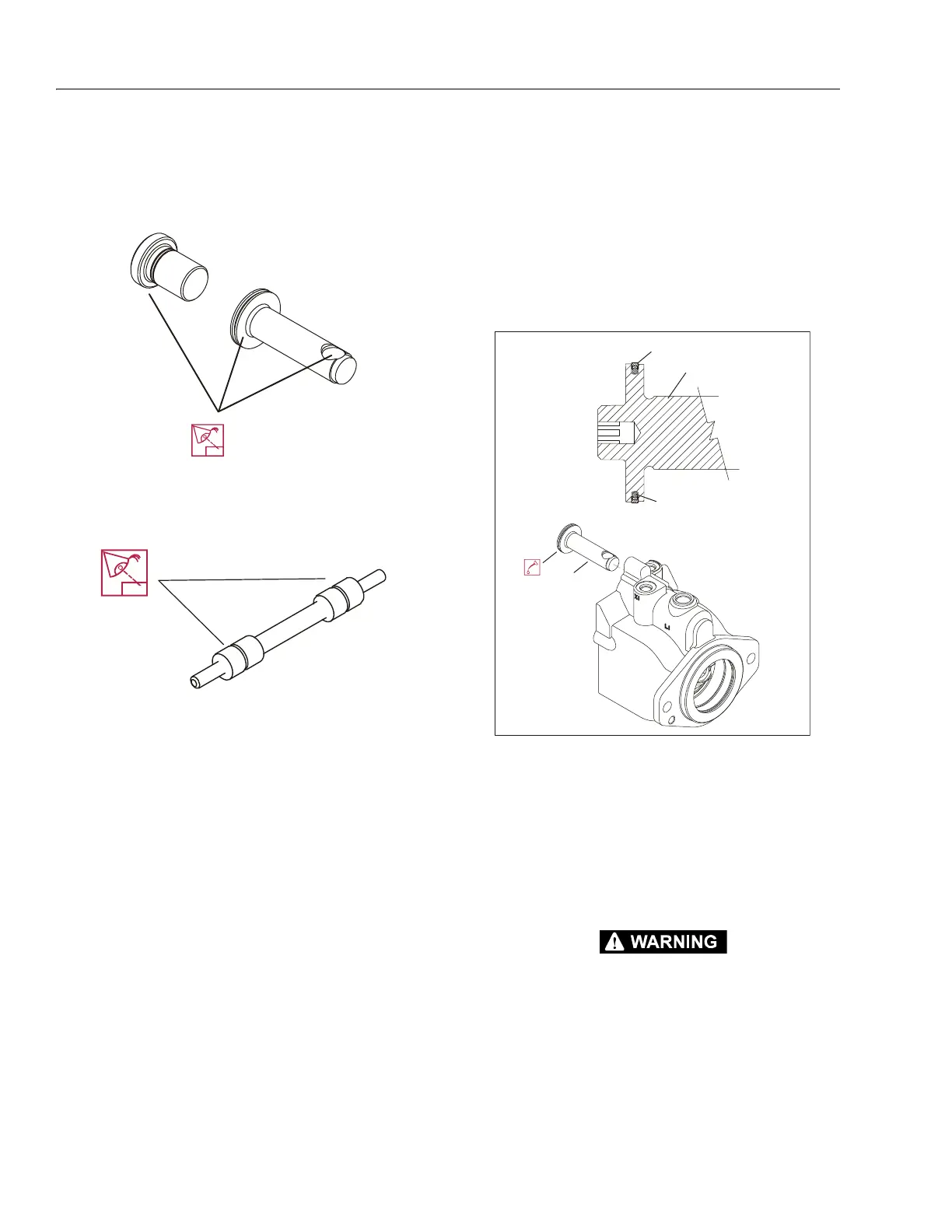

2. After piston seal has relaxed, lubricate and install servo

piston into the housing bore. Align the piston with the

ball socket facing the inside of the housing.

RISK OF PERSONAL INJURY: COMPRESSING THE BLOCK SPRING REQUIRES

ABOUT 80 TO 90 LBF (350 TO 400 N) OF FORCE. USE A PRESS SUFFICIENT TO

MAINTAIN THIS FORCE WITH REASONABLE EFFORT. ENSURE THE SPRING IS

SECURE BEFORE ATTEMPTING TO INSTALL THE SPIRAL RETAINING RING.

RELEASE THE PRESSURE SLOWLY AFTER THE RETAINING RING IS INSTALLED.

1. O-ring

2. Piston Seal

3. Servo Piston

Figure 3-17. Servo Piston

Loading...

Loading...