SECTION 4 - HYDRAULICS

4-6 – JLG Lift – 3121642

Apply a light film of hydraulic oil to all components prior to

assembly.

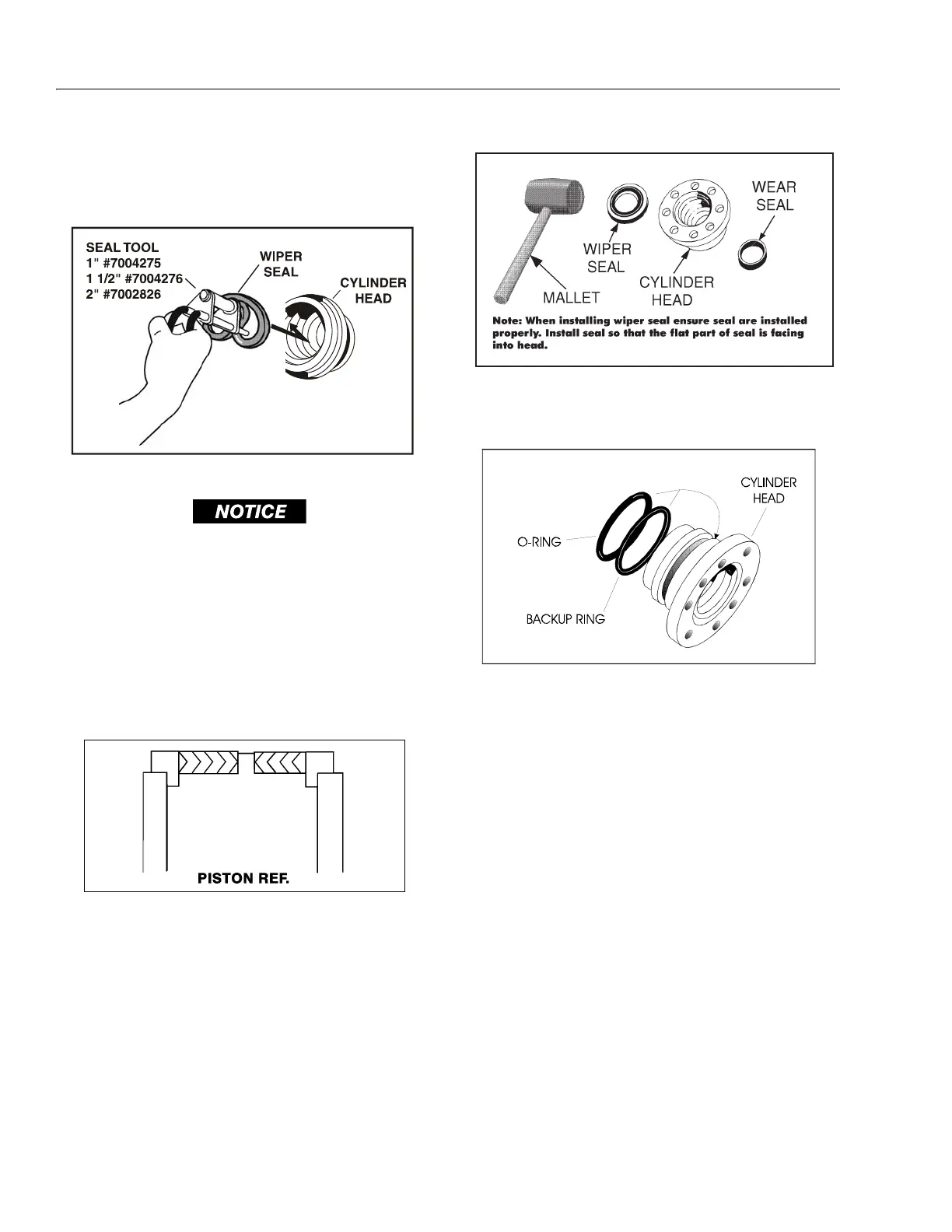

1. A special tool is used to install a new rod seal into the

applicable cylinder head gland groove.

WHEN INSTALLING ‘POLY-PAK’ PISTON SEALS, ENSURE SEALS ARE INSTALLED

PROPERLY. REFER TO WIPER SEAL INSTALLATION FOR CORRECT SEAL ORIEN-

TATION. IMPROPER SEAL INSTALLATION COULD RESULT IN CYLINDER LEAK-

AGE AND IMPROPER CYLINDER OPERATION.

WHEN INSTALLING THE WIPER SEAL ON THE LOWER (TOWER) LIFT CYLINDER,

APPLY LOCTITE® #609 ON THE WIPER SEAL IN THREE EVENLY SPACED PLACES

TO AID IN RETENTION OF THE SEAL.

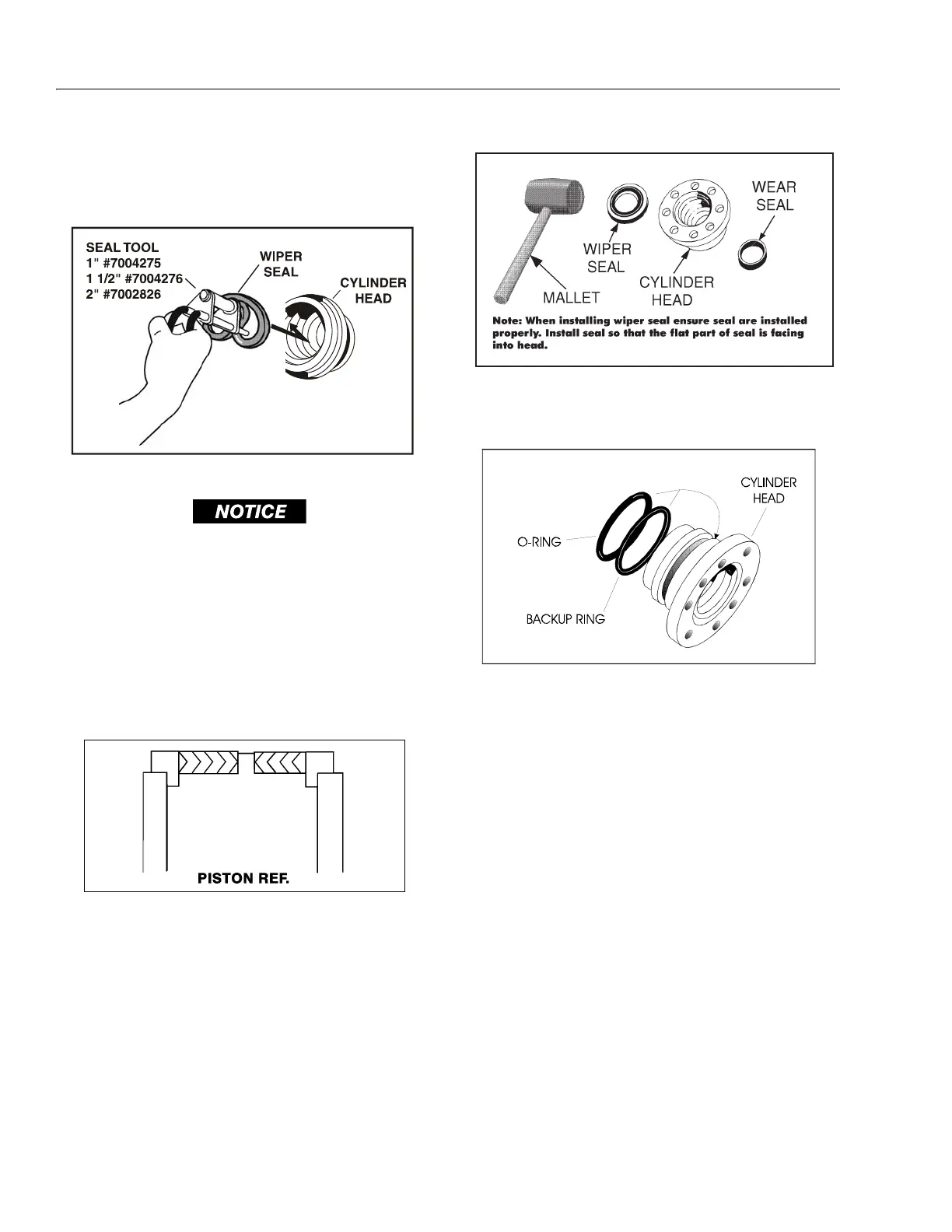

2. Use a soft mallet to tap a new wiper seal into the appli-

cable cylinder head gland groove. Install a new wear

ring into the applicable cylinder head glandgroove.

3. Place a new “o”ring and back-up seal in the applicable

outside diameter groove of the cylinder head.

4. Install washer ring onto rod. Carefully install the head

gland on the rod, ensuring that the wiper and rod seals

are not damaged or dislodged. Push the head along the

rod to the rod end, as applicable.

5. Carefully slide the piston spacer on the rod.

6. If applicable, correctly place new o-ring in the inner pis-

ton diameter groove. (The backup ring side facing the

O-ring is grooved.)

7. If applicable, correctly place new seals and guide lock

rings in the outer piston diameter groove. (A tube, with

I.D. slightly larger than the O.D. of the piston is recom-

mended to install the solid seal.)

NOTE: The backup rings for the solid seal have a radius on one

side. This side faces the solid seal. [See magnified insert in

(See Figure 4-11.)] The split of seals and backup rings must

be positioned so as not to be in alignment with each other.

Figure 4-7. Rod Seal Installation

Figure 4-8. Poly-Pak Piston Seal Installation

Figure 4-9. Wiper Seal Installation

Figure 4-10. Installation of Head Seal Kit

Loading...

Loading...