RIM

Tire Removal

DO NOT weld or apply heat on the rim assembly

with the tire mounted on the rim. Resulting gases

inside the tire may ignite causing explosion of tire.

When inflating tires always use a safety cage.

Never inflate a tire until the lockring is securely in

place. Do not stand in front of or over the lockring

during inflation procedures. Never overinflate a

tire. Refer to tire manufacturers recommenda-

tions.

1. Place tire and wheel assembly in safety cage and

discharge all air pressure from tire.

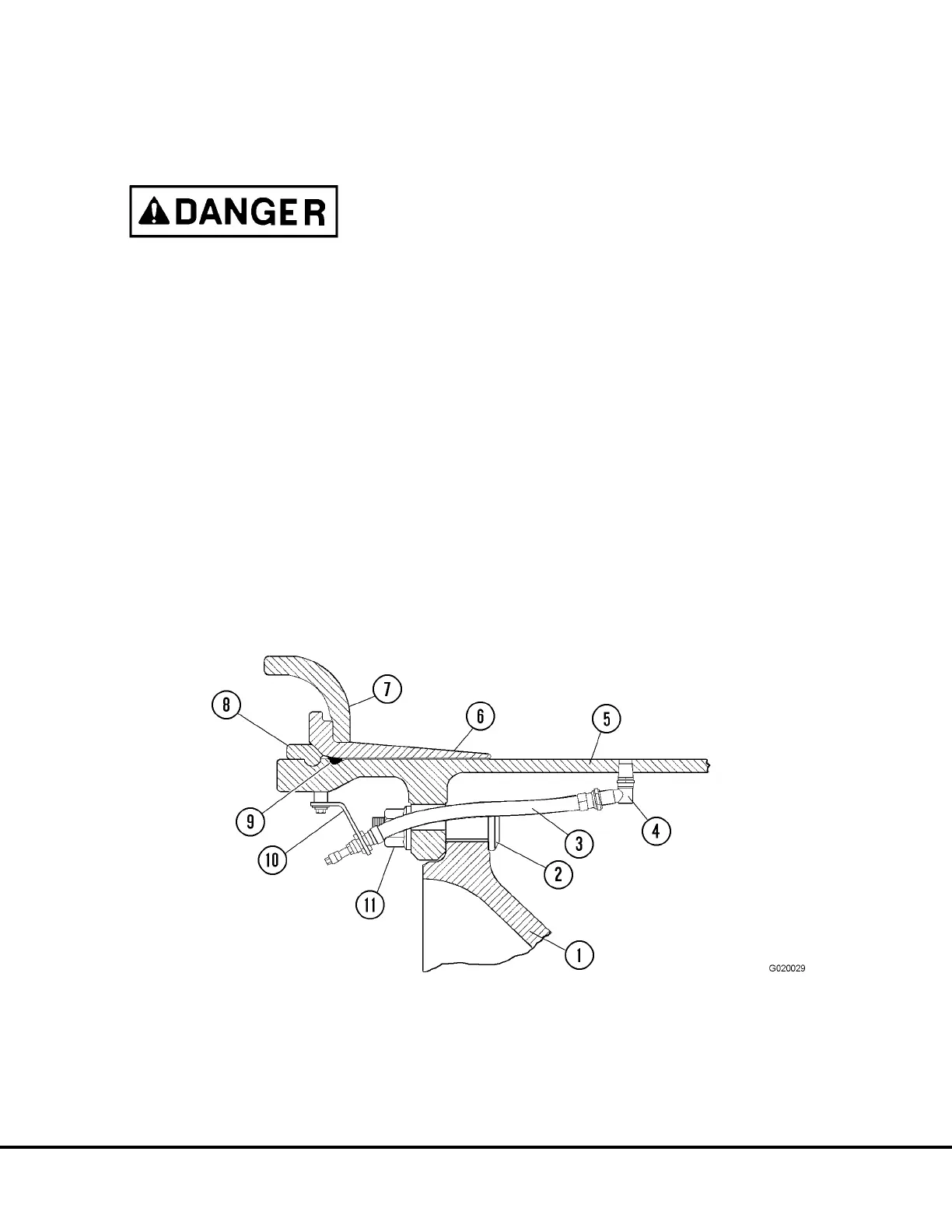

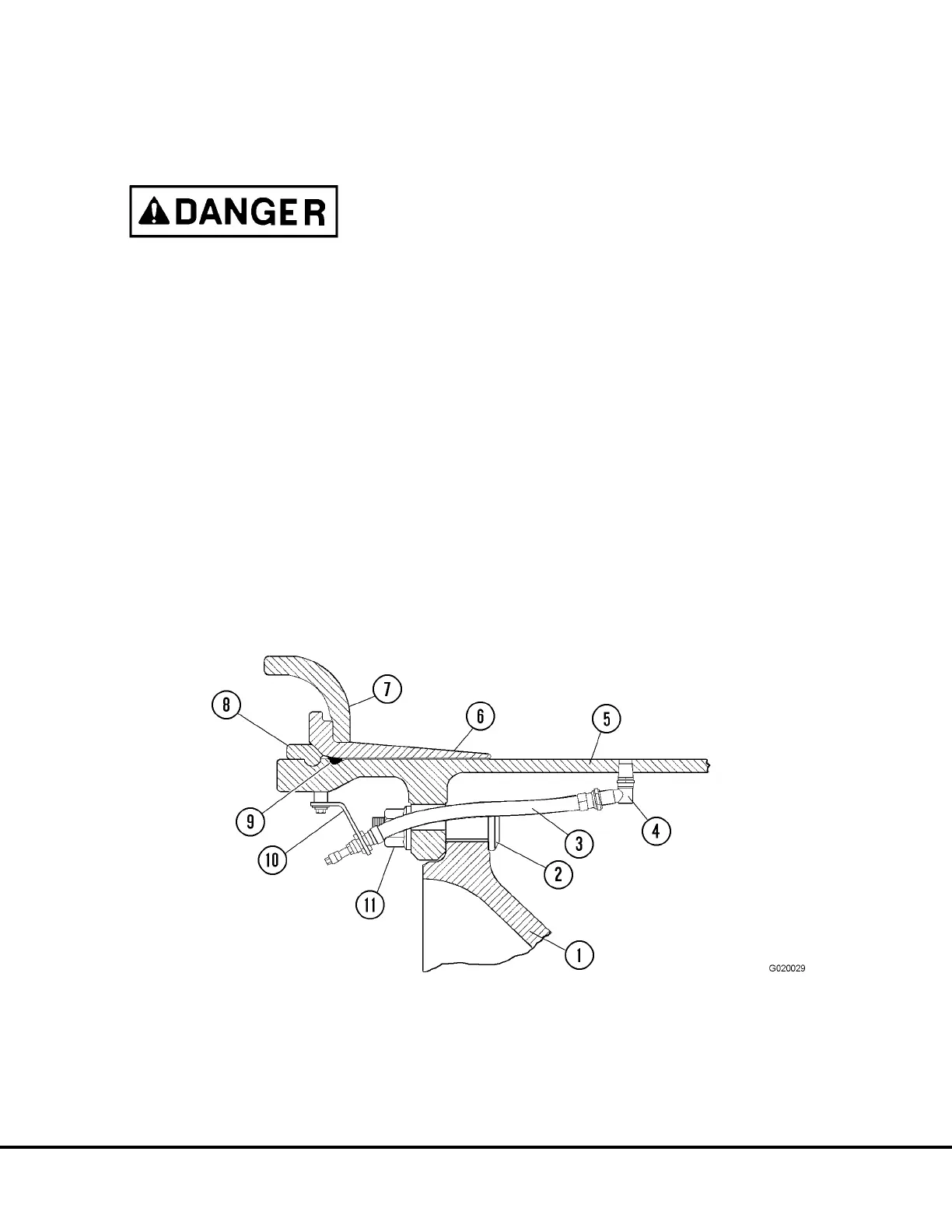

2. Attach a hydraulic bead breaker to the rim by

slipping the jaws of frame assembly over the outer

edge of flange (7, Figure 2-6). Make sure the jaws

of the frame are as near to the bead seat band (6)

as possible.

3. Following tool manufacturers instructions, move

tire bead in far enough to permit placing a wedge

between tire and flange at side of tool.

4. Repeat this procedure at locations approximately

90° from the first application. Continue this pro-

cedure until tire bead is free from rim.

5. After bead is broken loose, insert flat of tire tool in

beading notch on lockring (8). Pry lockring up and

out of groove on rim.

6. Pry in on bead seat band (6) until O-ring (9) is

exposed. Remove O-ring.

7. Remove bead seat band (6) from rim (5) and

remove flange (7).

8. Reposition wheel assembly and repeat removal

procedure on opposite side of tire. Remove tire

from rim.

FIGURE 2-6. FRONT WHEEL HUB AND RIM ASSEMBLY

1. Wheel Hub

2. Stud

3. Tire Inflation Hose

4. Swivel Connector

5. Rim

6. Bead Seat Band

7. Side Flange

8. Lock Ring

9. O-Ring

10. Clamp Bracket

11. Flanged Nut

G2-6 Tires and Rims G02015

Loading...

Loading...