FRONT BEARING REMOVAL

1. Remove retaining ring (1, Figure 13-23) from front

outer side of front housing.

2. Remove retaining ring (3, Figure 13-23) from rear

inner side of front housing.

3. Support front housing on blocks and with a press,

remove front bearing (4, Figure 13-23) from front

housing. Use Tool BF4818 (Figure 13-24).

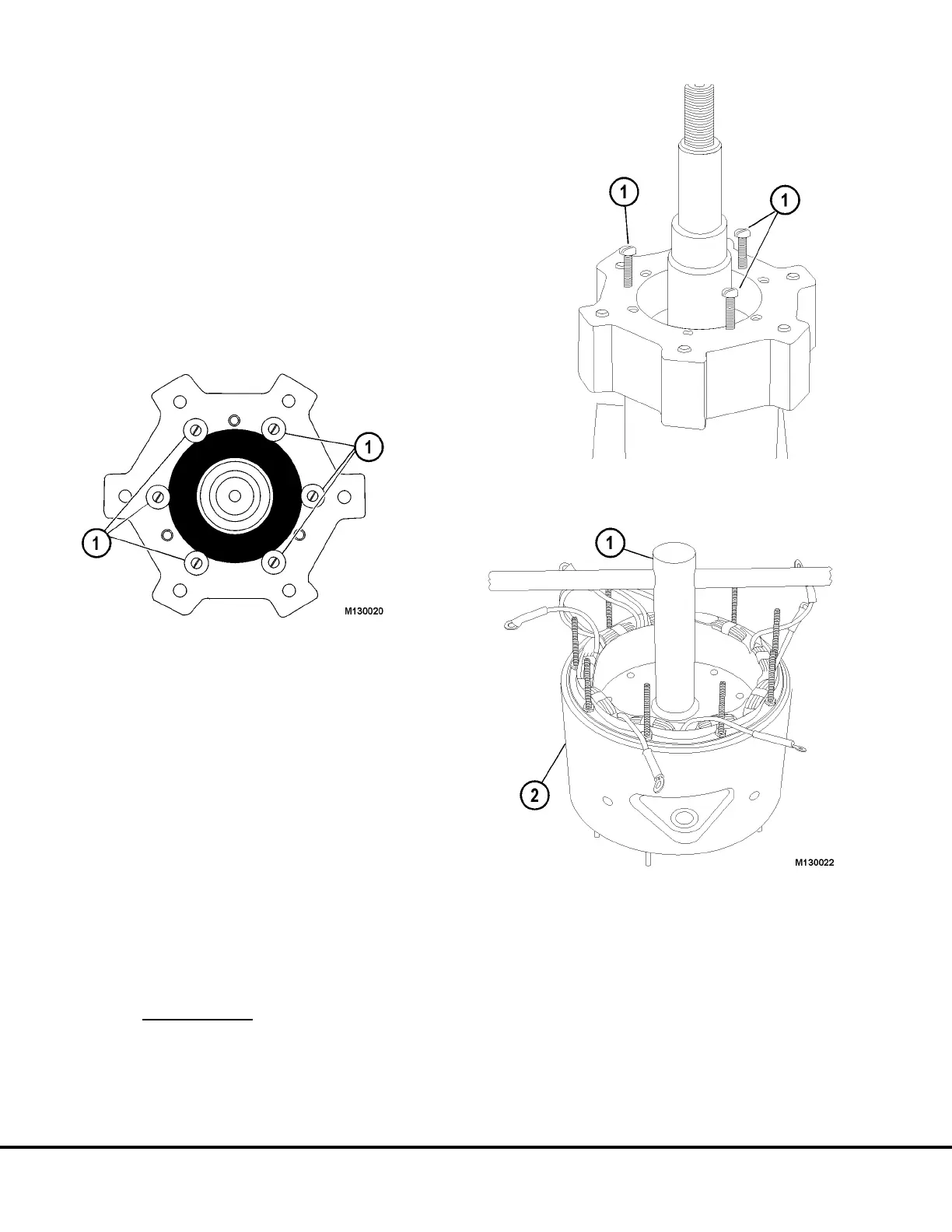

FRONT ROTOR REMOVAL

1. Remove six flanged locknuts from core studs or

six self tapping screws (Figure 13-16).

2a. Use three 10-32 UNF x 2” long machine screws

as Jacks in the three threaded holes of rotor end

plate (Figure 13-17). Pull rotor off core gradually

by working screws against core in sequence.

Alternate Method

2b. Using an air hammer (air chisel) with a blunt

tipped tool, vibrate the area around the rotor

element to rotor core attaching studs. The vibra-

tions should loosen the built up rust in that area.

Remove the rotor element. If resistance is still felt,

use the method described in “2a.” above, plus the

air hammer.

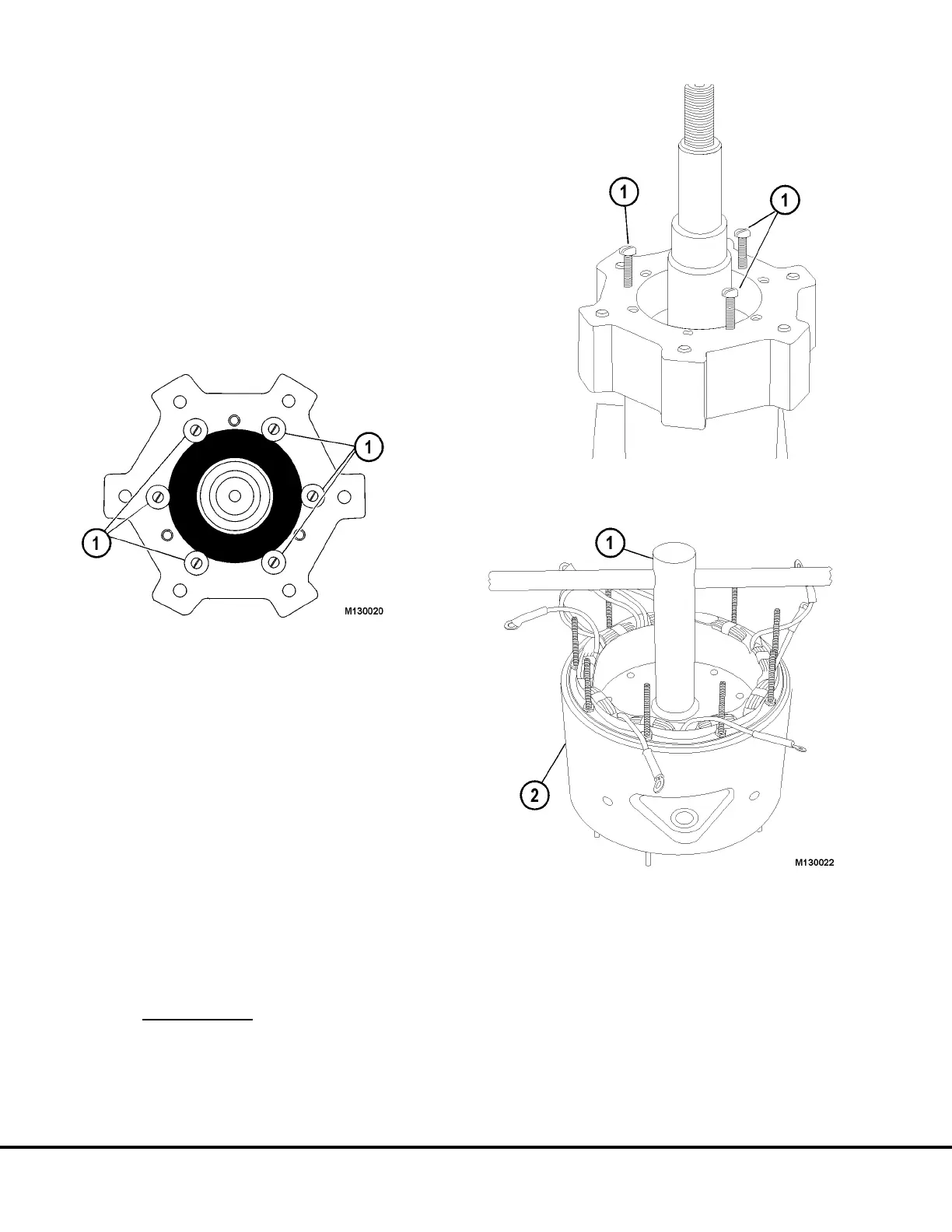

FIELD COIL REMOVAL

Do not attempt to repair field coil.

Replace the whole assembly.

1. Mark the position of field coil leads (white wires

with spade terminals) on stator. New fields will be

positioned in same opening in stator assembly,

as the old field leads.

2. Remove the screws attaching field coil bobbin to

stator tabs (Figure 13-18).

3. Use tool BF4820 to rotate field coil bobbin about

20 degrees to disengage bobbin ears from stator

tabs.

Note: Some force may be required to break the perma-

fill coating on the tabs.

FIGURE 13-16.

1. Flanged Locknuts or Screws

FIGURE 13-17.

1. Jack Screws

FIGURE 13-18.

1. Bobbin Removal Tool 2. Stator & Shell Assembly

(BF4820)

M13-16 Niehoff Alternator Overhaul Manual M13003 04/01

Loading...

Loading...