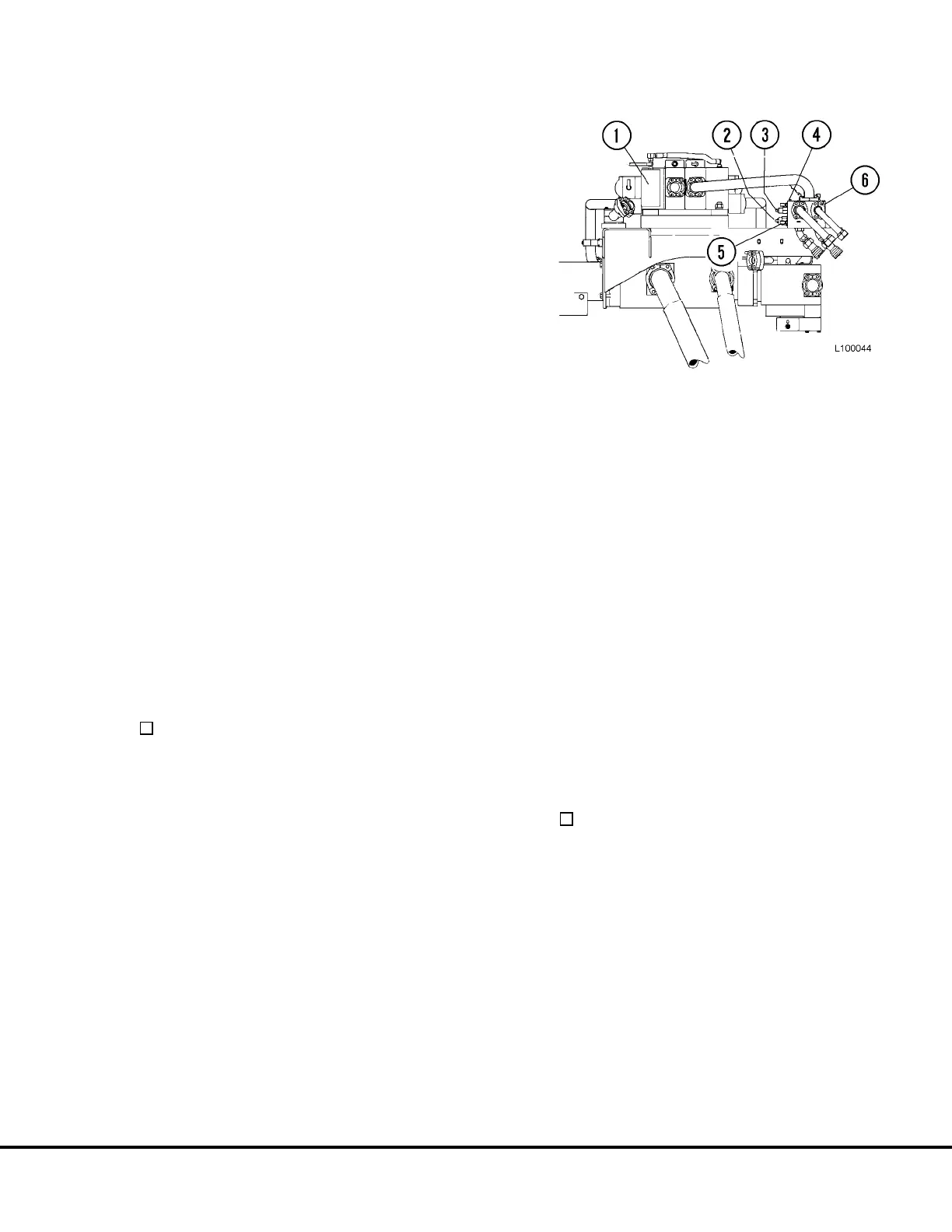

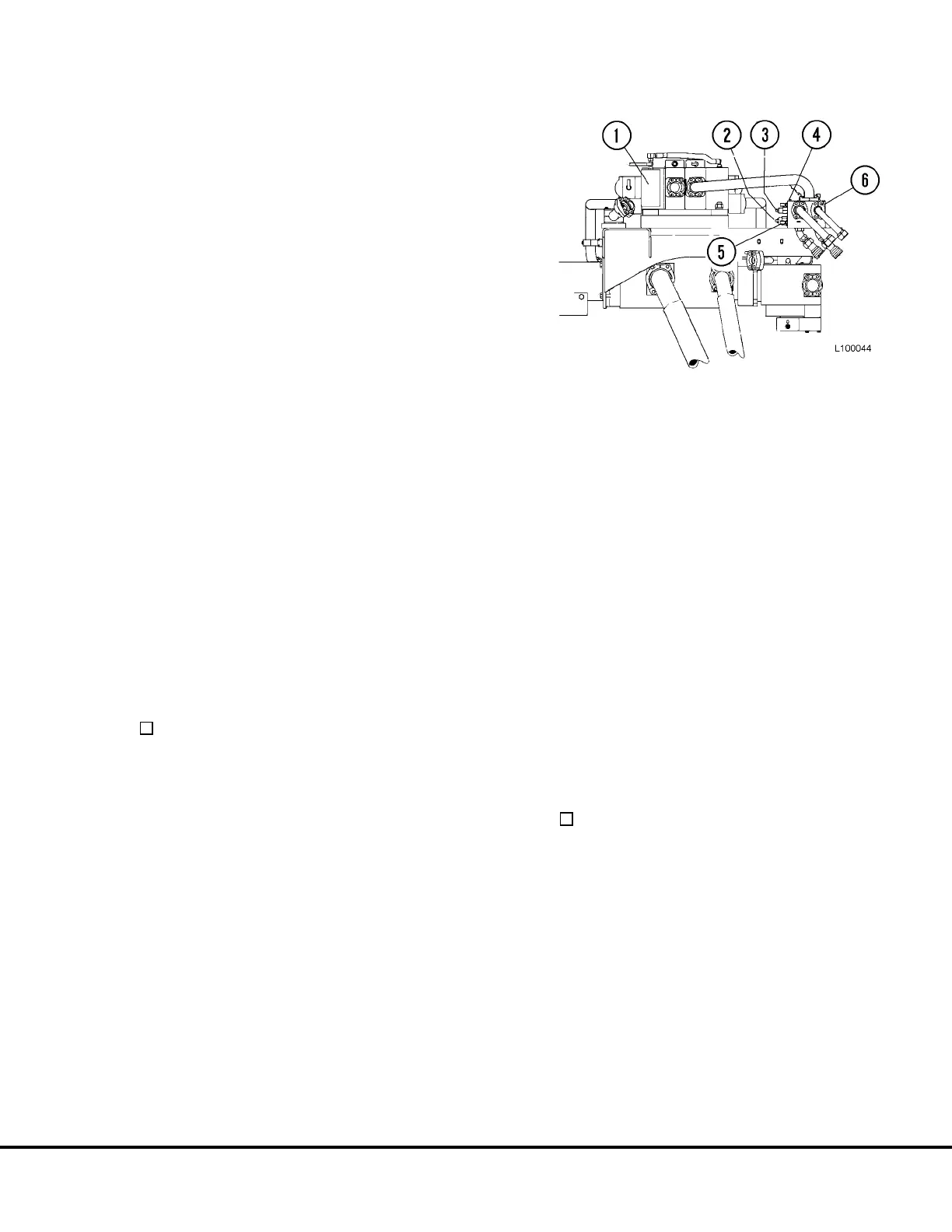

Hoist Counterbalance Valve Adjustment

Preparation:

1. With the engine shut down, the body resting on

the frame, the hoist valve in the FLOAT position

and hydraulic system pressure bled down,

loosen locknut on adjustment stem of needle

valve (3, FIGURE 10-8) on overcenter manifold

(6). Turn adjustment stem fully clockwise.

2. Remove plug from “PILOT VENT” port (4) on

overcenter manifold. This port will remain open

to atmosphere during adjustment; do not allow

dirt to enter open port.

Note: It is suggested a clean SAE #4 (1/4") hydraulic

hose is installed in the open port and the hose pointed

downward.

3. Install a 5000 psi (35,000 kPa) gauge at test port

“TR” on overcenter manifold. (Gauge will meas-

ure rod end pressure; the pressure controlled by

the counterbalance valve.)

Counterbalance Valve Pressure Check Only:

1. Start the engine. At low idle, raise the body and

as it extends to the third stage, read the pressure

on the gauge connected to the “TR” port. (All

counterbalance valve pressures are read/ad-

justed while hoist cylinders are in third stage.)

a. If pressure is 3000 psi (20.7 MPa) or above,

stop hoisting immediately.

Pressure is adjusted too high and must be

lowered. Go to “Counterbalance Valve Ad-

justment” and perform adjustment procedure.

b. If pressure is below 3000 psi (20.7 MPa),

increase engine speed by approximately 300

rpm and observe pressure on gauge.

1.) If pressure is still below 3000 psi (20.7 MPa),

continue increasing engine speed in steps of

300 rpm, while in third stage and observing

pressure gauge.

2.) Continue monitoring pressure gauge until

engine high idle is attained.

c. If gauge indicates 3000 psi (20.7 MPa) while

at high idle, in POWER UP and in third stage,

counterbalance valve adjustment is correct.

d. If gauge does not indicate 3000 psi (20.7 MPa)

while in third stage and at high idle (or a lesser

rpm during step 1b, 1.) perform “Counterbal-

ance Valve Adjustment” procedure.

Counterbalance Valve Adjustment

1. Loosen locknut on adjustment stem of counter-

balance valve (2, FIGURE 10-8) (Labeled “CBV”

on manifold). Turn adjustment stem fully clock-

wise to start adjustment procedure so counter-

balance valve pressure is as low as possible.

Note: Turning adjustment stem in (clockwise) de-

creases the pressure. Turning the stem out (counter-

clockwise) increases the pressure.

Complete valve

adjustment range is 3 turns.

2. Start the engine and operate at high idle. Raise

the body while observing the pressure gauge.

Slowly adjust counterbalance valve to obtain

3000 psi (20.7 MPa) as the hoist cylinder 3rd

stage extends while in POWER UP. When

adjustment is complete, secure locknut on

adjustment stem.

3. Repeat Counterbalance Valve Pressure Check,

step 1. to verify proper adjustment.

* Record on Data Sheet

4. Replace plug in “PILOT VENT” port. Remove

pressure gauge.

5. Turn needle valve adjustment stem fully out and

secure locknut.

FIGURE 10-8. COUNTERBALANCE VALVE

ADJUSTMENT

1. Hoist Valve

2. Counterbalance Valve

3. Needle Valve

4. “Pilot Vent” Port Plug

5. “TPD” Pressure Test Port

6. Overcenter Manifold

L10012 Hydraulic Check-out Procedure L10-9

Loading...

Loading...