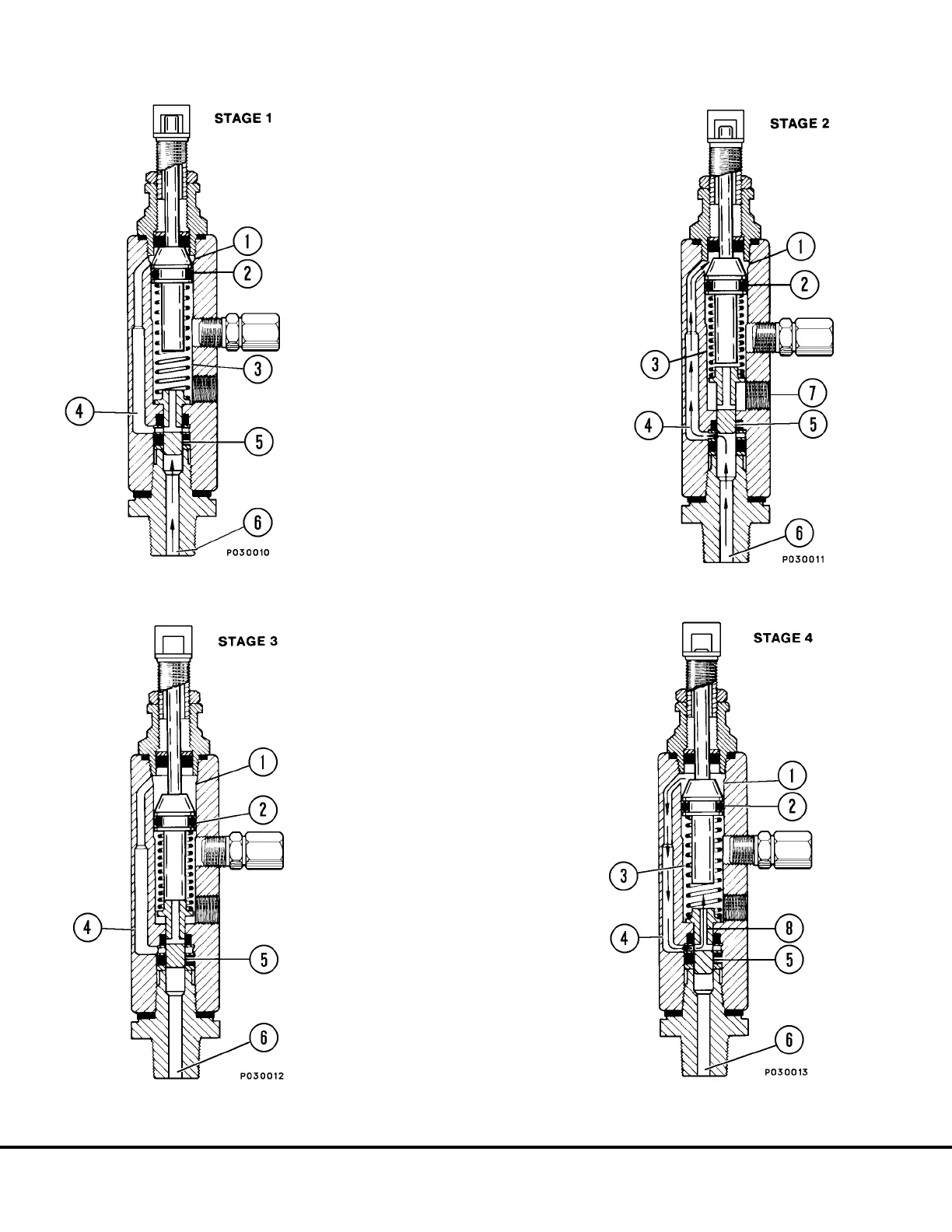

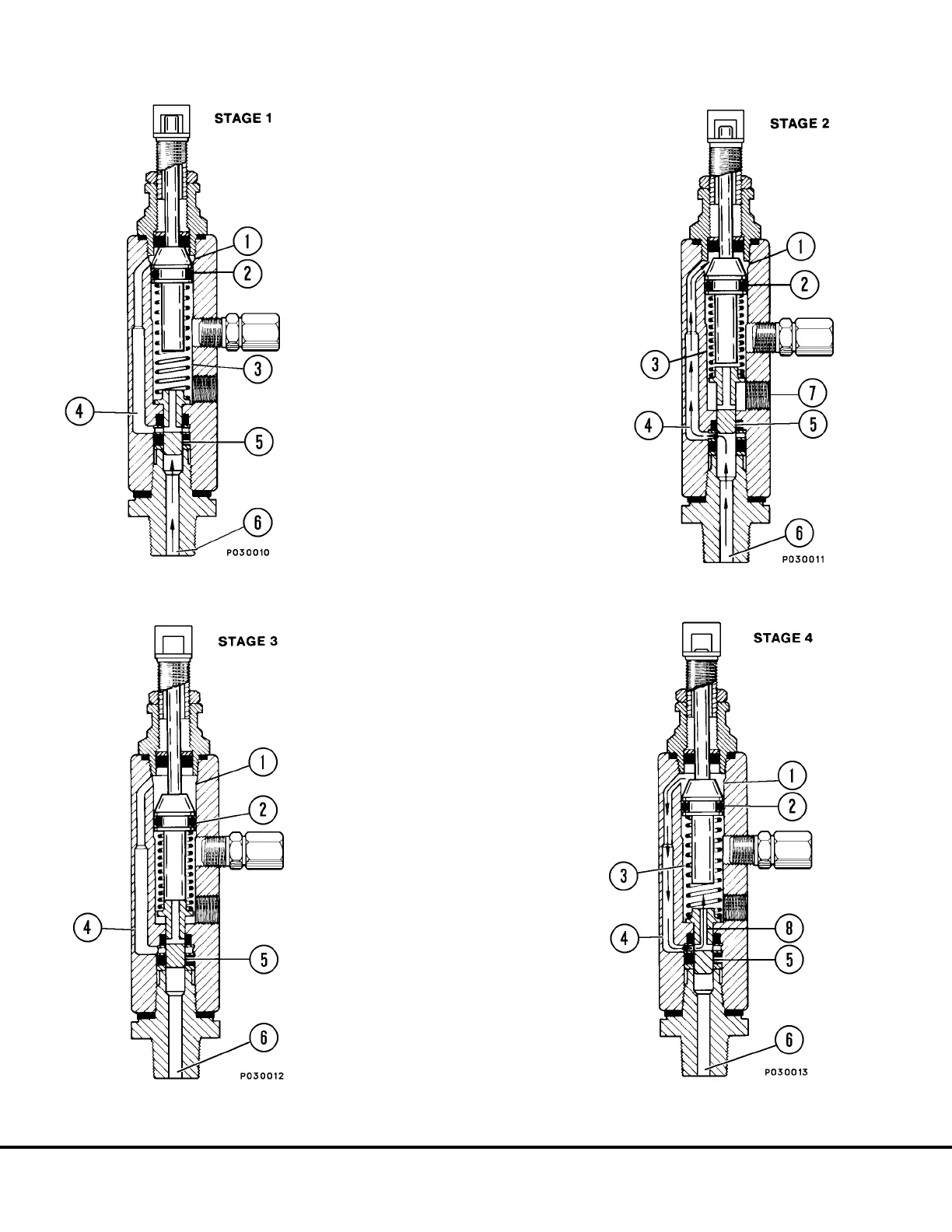

INJECTOR OPERATION

STAGE 1.

The injector piston (2) is in its normal or

“rest” position. The discharge chamber (3)

is filled with lubricant from the previous

cycle. Under the pressure of incoming lubri-

cant (6), the slide valve (5) is about to open

the passage (4) leading to the measuring

chamber (1) above the injector piston (2).

STAGE 2.

When the slide valve (5) uncovers the pas-

sage (4), lubricant (6) is admitted to the

measuring chamber (1) above the injector

piston (2) which forces lubricant from the

discharge chamber (3) through the outlet

port (7) to the bearing.

STAGE 3.

As the injector piston (2) completes its

stroke, it pushes the slide valve (5) past the

passage (4), cutting off further admission of

lubricant (6) to the passage (4) and meas-

uring chamber (1). The injector piston (2)

and slide valve (5) remain in this position

until lubricant pressure in the supply line (6)

is vented.

STAGE 4.

After venting, the injector spring expands,

causing the slide valve (5) to move, so that

the passage (4) and discharge chamber (3)

are connected by a valve port (8). Further

expansion of the spring causes the piston

to move upward, forcing the lubricant in the

measuring chamber (1) through the pas-

sage (4) and valve port (8) to refill the

discharge chamber (3).

Injector is now ready for the next cycle.

P3- 6 Automatic Lubrication System P03018 4/00

Loading...

Loading...