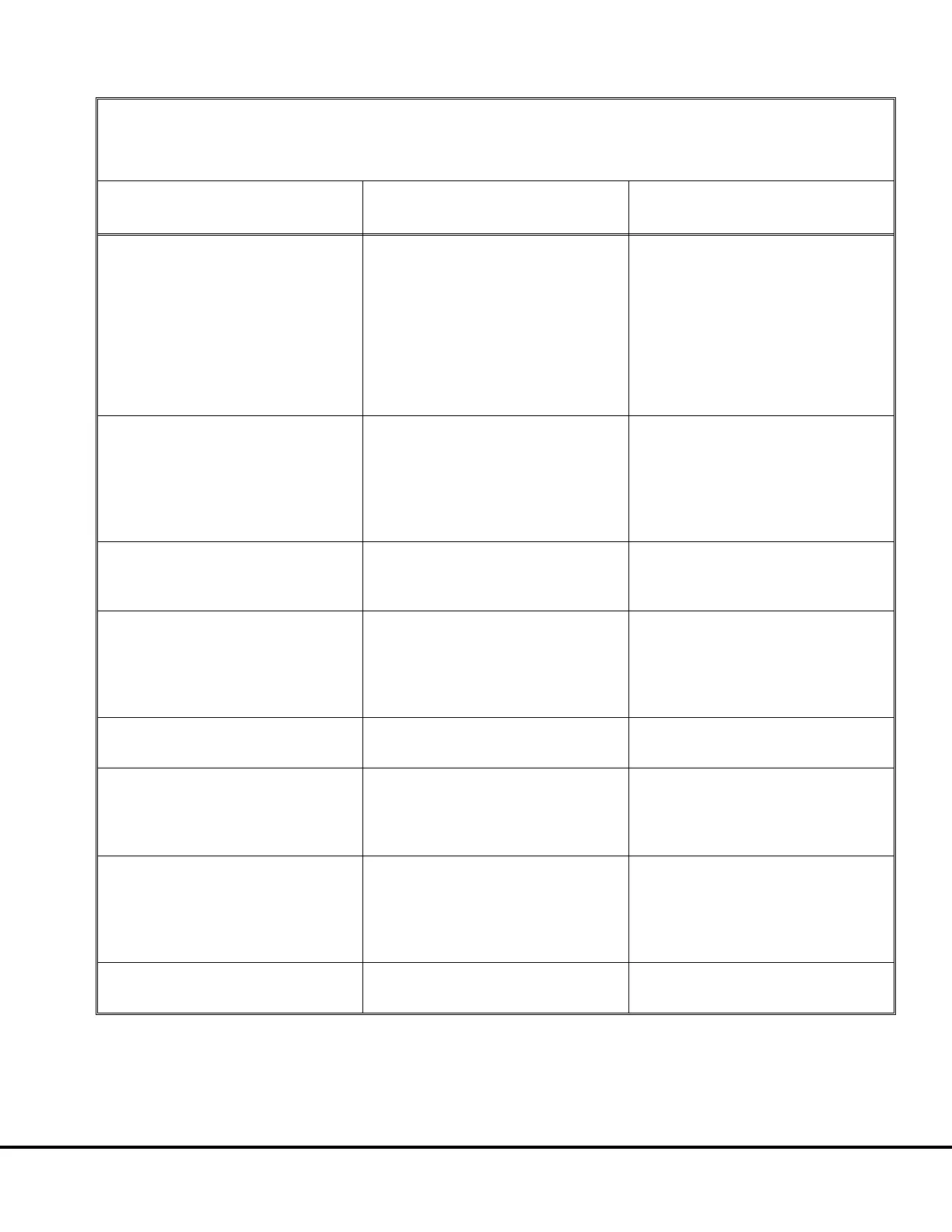

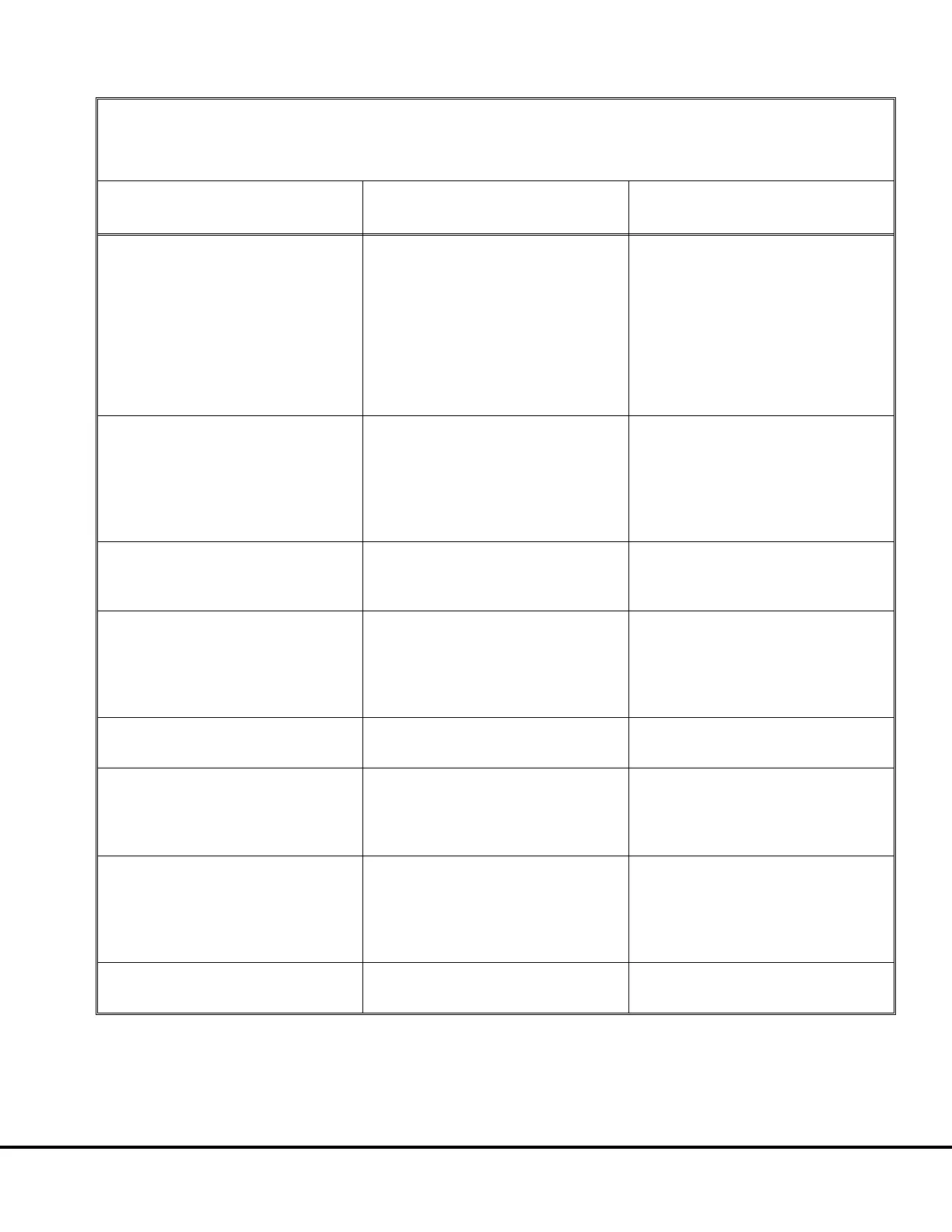

TROUBLESHOOTING GUIDE

(HOIST PUMP)

TROUBLE POSSIBLE CAUSE SUGGESTED CORRECTIVE

ACTION

1. Sandblasted band around pressure

plate bores

2. Angle groove on face of pressure

plate

3. Lube groove enlarged and edges

rounded

4. Dull area on shaft at root of tooth

5. Dull finish on shaft in bearing area

6. Sandblasted gear bore in housing

1. Abrasive wear caused by fine

particles.

a. Dirt (fine contaminants, not visible

to the eye)

1. Was clean oil used?

2. Was filter element change period

correct?

3. Were correct filter elements used?

4. Hoist cylinder rod wiper and seals in

good condition?

5. Cylinder rods dented or scored?

6. Was system flushed properly after

previous failure?

1. Scored pressure plates.

2. Scored shafts

3. Scored gear bore

2. Abrasive wear caused by metal

particles

a. Metal (coarse)contaminants,

visible to the eye

1. Was system flushed properly after

previous failure?

2. Contaminants generated elsewhere

in hydraulic system?

3. Contaminants generated by wearing

pump components?

1. Any external damage to pump

2. Damage on rear of drive gear and

rear pressure plate only

3. Incorrect installation 1. Did shaft bottom in mating part?

2. Any interference between pump and

machine?

1. Eroded pump housing

2. Eroded pressure plates

4. Aeration-Cavitation

a. Restricted oil flow to pump inlet

b. Aerated Oil

1. Tank oil level correct?

2. Oil viscosity as recommended?

3. Restriction in pump inlet line?

4. Air leak in pump inlet line?

5. Loose hose or tube connection?

1. Heavy wear on pressure plate

2. Heavy wear on end of gear

5. Lack of oil 1. Was oil level correct?

2. Any leaks in piping inside tank?

1. Housing scored heavily

2. Inlet peened and battered

3. Foreign object caught in gear teeth

6. Damage caused by metal object 1. Metal object left in system during

initial assembly or previous repair?

2. Metal object generated by another

failure in system?

1. Pressure plate black

2. O-rings and seals brittle

3. Gear and journals black

7. Excessive Heat 1. Metal object left in system during

initial assembly or previous repair?

2. Was relief valve setting too low?

3. Was oil viscosity correct?

4. Was oil level correct?

1. Broken shaft

2. Broken housing or flange

8. Over Pressure 1. Relief valve setting correct?

2. Did relief valve function?

L03027 Hydraulic Component Repair L3-13

Loading...

Loading...