Assembly of Cylinder

1. Install seals (15, Figure 8-20) and bearing (14)

on second stage cylinder. Install bearings (19)

and buffer seal (18), rod seal (20) and rod wiper

(21) on first stage cylinder. Lubricate with clean

hydraulic oil (Type C-4).

2. Align and slide the second stage cylinder (2)

inside the first stage cylinder (3). Allow the sec-

ond stage to protrude far enough to install the

snap ring (9) on the inside of the first stage

cylinder.

3. Mount the housing (4) in the fixture with the cover

end positioned at the top. Install bearings (19)

and buffer seal (18), rod seal (20) and rod wiper

(21) in the housing.

4. Install lifting tool used during disassembly in the

second and first stage cylinder assembly.

5. Install bearings (13 & 24) on the first stage

cylinder (3). Lift and align this assembly over the

housing (4). Lower the second and first stage

cylinders into the housing.

6. Install retainer used during disassembly to hold

the second and first stage cylinder in place when

the housing is rotated. Rotate housing 180

o

to

position the lower mounting eye at the top.

7. Install bearings (19) and buffer seal (18), rod seal

(20) and rod wiper (21) in the second stage

cylinder (2). Note the proper orientation of the

rod seal (20) backup ring; install with radi-

used corner toward seal and white dot away

from seal.

8. Attach a lifting device to the rod eye (1) and align

it over the housing (4). Lower the rod into the

housing. Lubricate the rod with hydraulic oil.

9. Rotate housing 180° to position the cover end at

the top. Remove retainer installed in Step 5.

Install bearings (17) and seal (16) on the rod

bearing retainer (6).

10. Thread two guide bolts 4 in. (100 mm) long in the

end of the rod (1). Install seal (8) on the end of

the rod.

11. Align piston rod bearing retainer (6) over guide

bolts and lower it over the end of the rod (1).

Remove guide bolts.

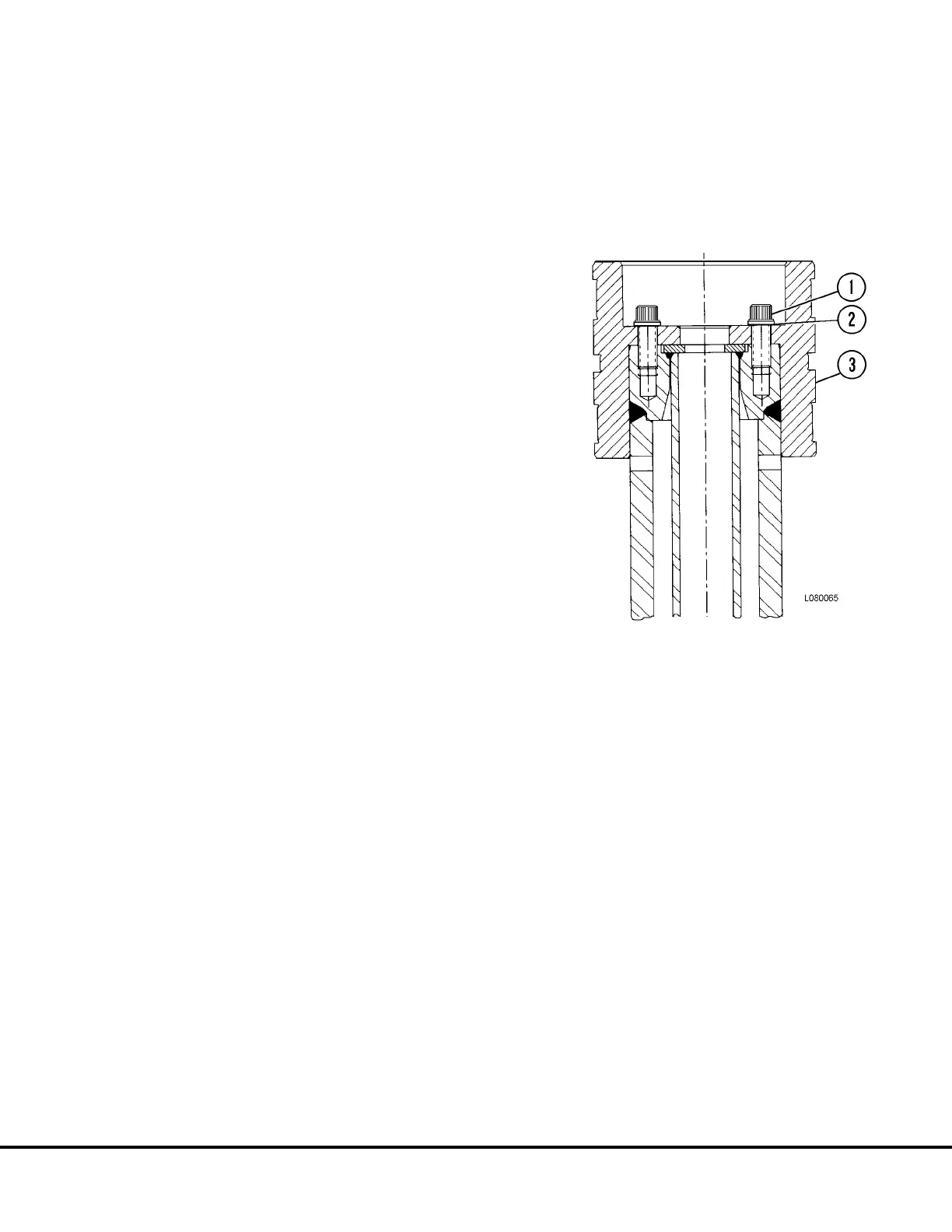

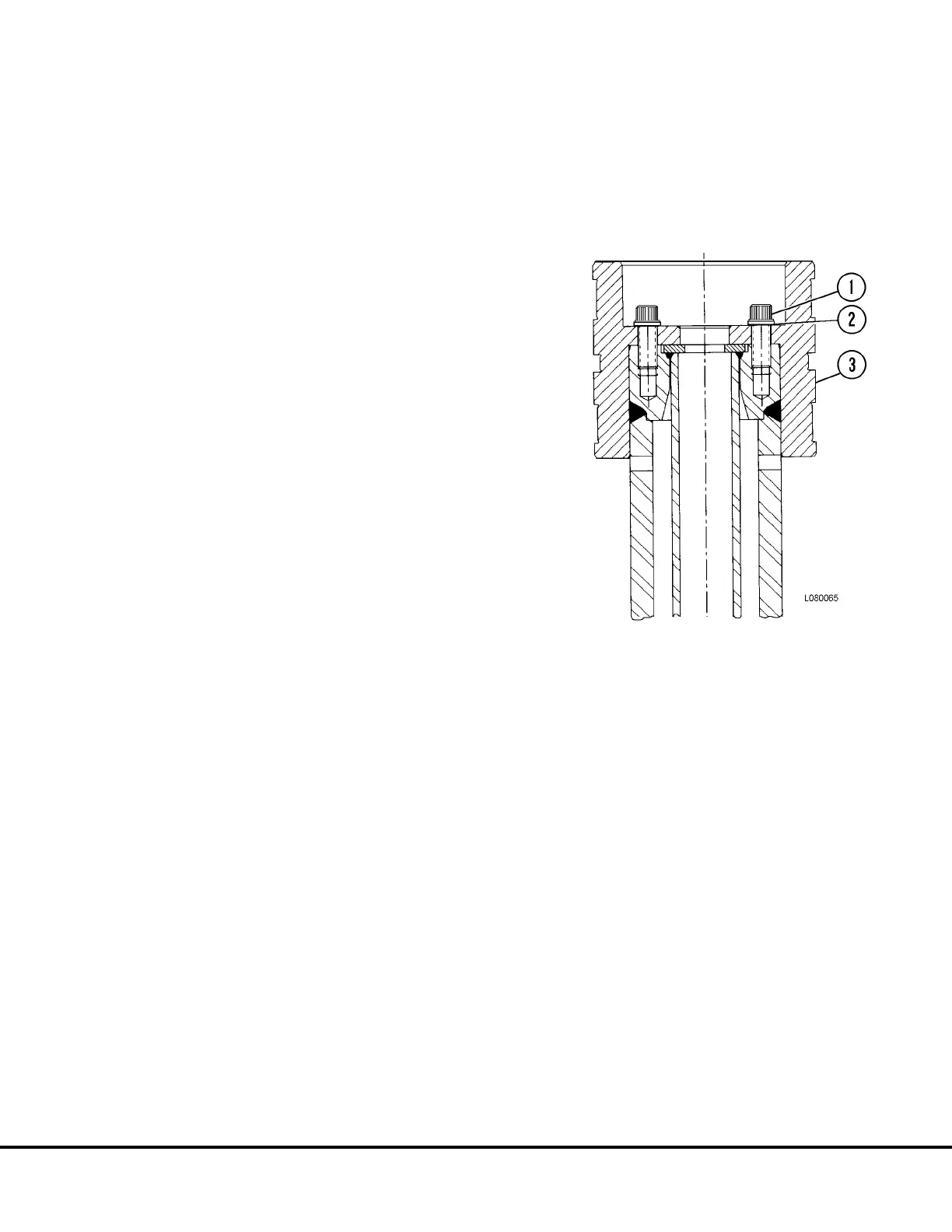

NOTE: Check capscrews (1, Figure 8-24) carefully for

distress and, if in doubt, replace them with new parts.

12. Lubricate capscrews (1, Figure 8-24) with a lith-

ium base grease. Install capscrews and plate (2)

and tighten to 575 ft. lbs. (780 N.m) torque.

13. Install O-ring (12, Figure 8-20) and backup ring

(23) on cover (10). Align and lower cover onto

housing (4). Lubricate capscrews (11), install

capscrews and lockwashers. Tighten capscrews

to 500 ft. lbs. (678 N.m) torque.

14. Install hoist cylinder eye bearing (5, Figure 8-19)

and retainer rings (4) if removed.

FIGURE 8-24. 3rd STAGE PISTON

1. 12 Pt. Capscrew

2. Plate

3. Piston

L08024 Hoist Circuit Component Repair L8-19

Loading...

Loading...