CONTROL UNIT ASSEMBLY REPLACEMENT

Refer to Figures 13-30 and 13-31 for the following

steps:

1. Hold the new regulator connector harness in its

approximate installation position and bend wires

into their proper position.

2. Solder both the regulator connector lead “3”, and

the output lead from “B+” buss, to the terminal

block, “B+” position. (right of center)

3. Position nuts on the terminal block attaching

screws about 2 threads from the tip of the screw.

NOTE: These nuts are used as spacers.

4. Attach the terminal block to the alternator housing.

CAUTION: Thread both screws in evenly so as not

to cock the terminal block. Failure to keep the

terminal block parallel to the housing may break

the terminal block.

5. Attach the ground lead from the regulator harness

(lead “2”) to the housing.

6. Route the regulator harness under “B+” buss

leads. Care should be taken to keep the regulator

connector flat with “A” pin properly positioned.

NOTE: Wires in steps 7 & 8 should slant away from

both “E” & “R” terminals (down and left, as viewed from

outside).

7. Position the insulating sleeving over wire termi-

nals prior to attaching ring terminals to “E” & “R”

(or phase terminals) studs.

NOTE: Assembly sequence for “E” & “R” terminal (or

phase terminals) is: insulator-flat washer-terminal-nut.

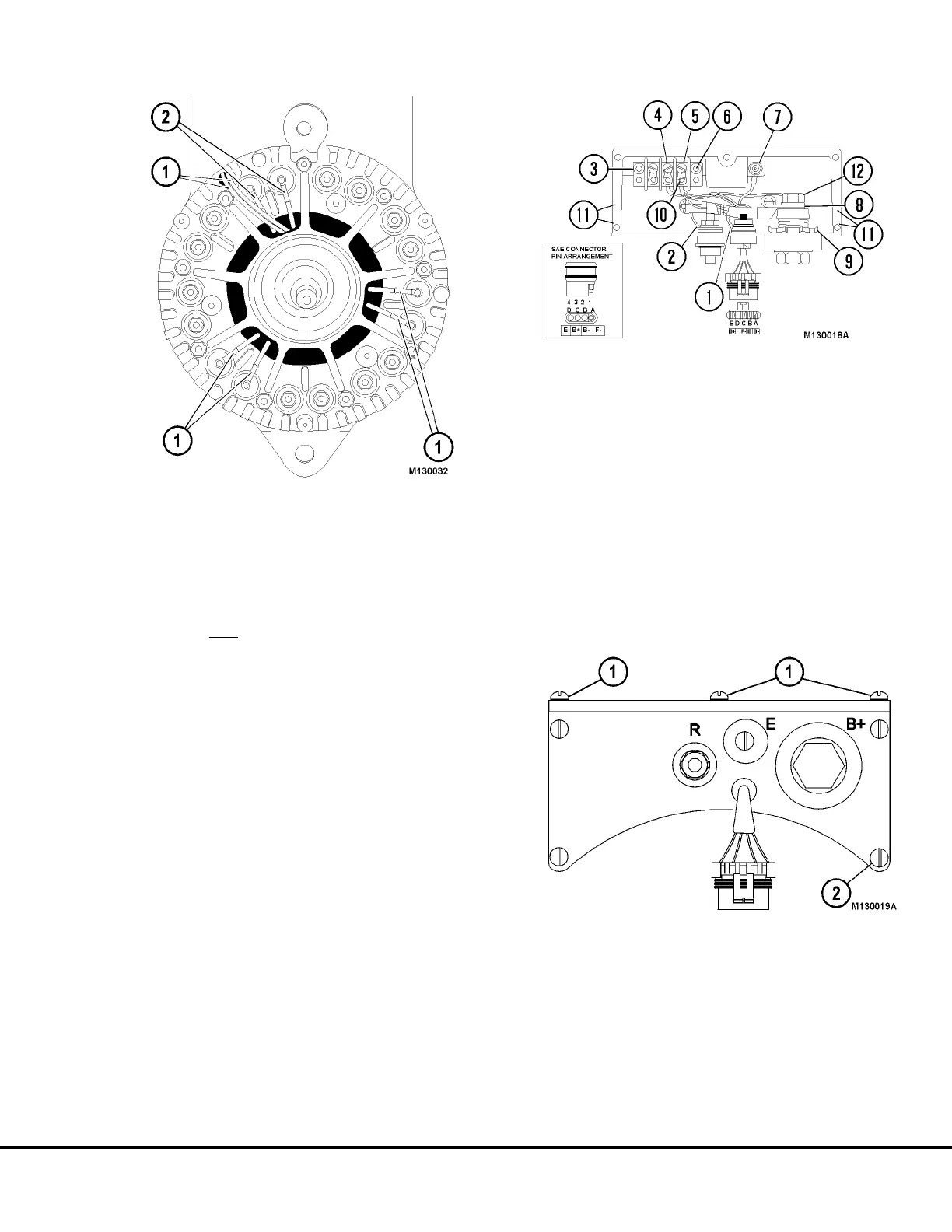

FIGURE 13-29.

1. Field Leads 2. Phase Leads

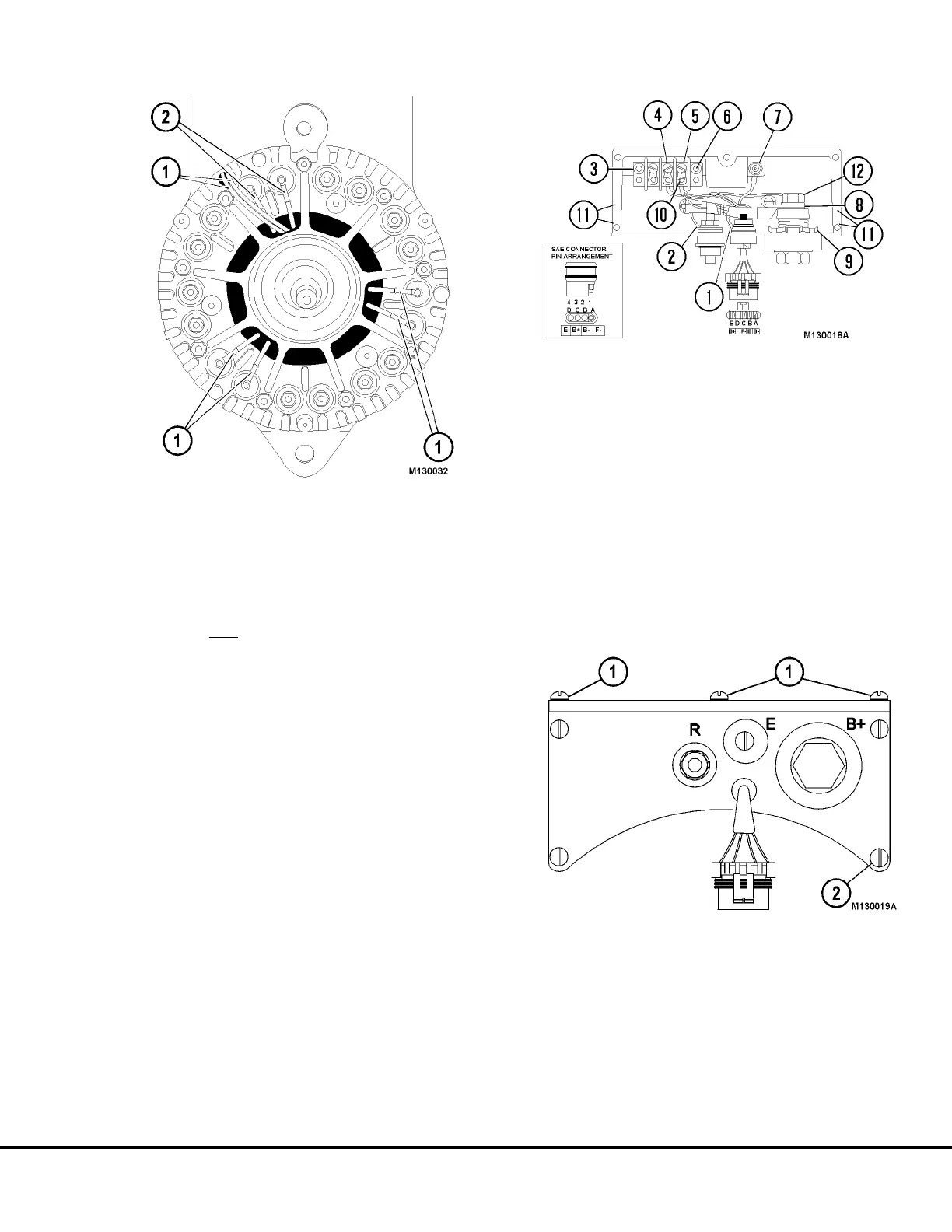

FIGURE 13-30. CONTROL UNIT ASSEMBLY

1. Ignition (E) (Harness Lead #4)

2. Relay (R)

3. Terminal Block

4. F- (Harness Lead #1)

5. F+ (Harness Lead #3); 10 in. lbs. (1.3 Nm) torque

6. Terminal Block Screw; 30 in. lbs. (3.5 Nm) torque

7. Ground Wire from Regulator (Harness Lead #2)

24 in. lbs. (2.7 Nm) torque

8. B+ Buss Leads to Rectifier

9. When replacing output stud only; tighten to

12-15 ft.lbs. (16-20 N.m) torque, and coat with

epoxy.

10. Solder here.

11. Apply RTV here.

12. Tighten to 180 in.lbs. (20 N.m) torque.

FIGURE 13-31.

1. Cover Screws (TOP) 2. Control Unit Screw

Tighten nine screws to 20 in.lbs. (2.3 N.m) torque.

M13003 04/01 Niehoff Alternator Overhaul Manual M13-21

Loading...

Loading...