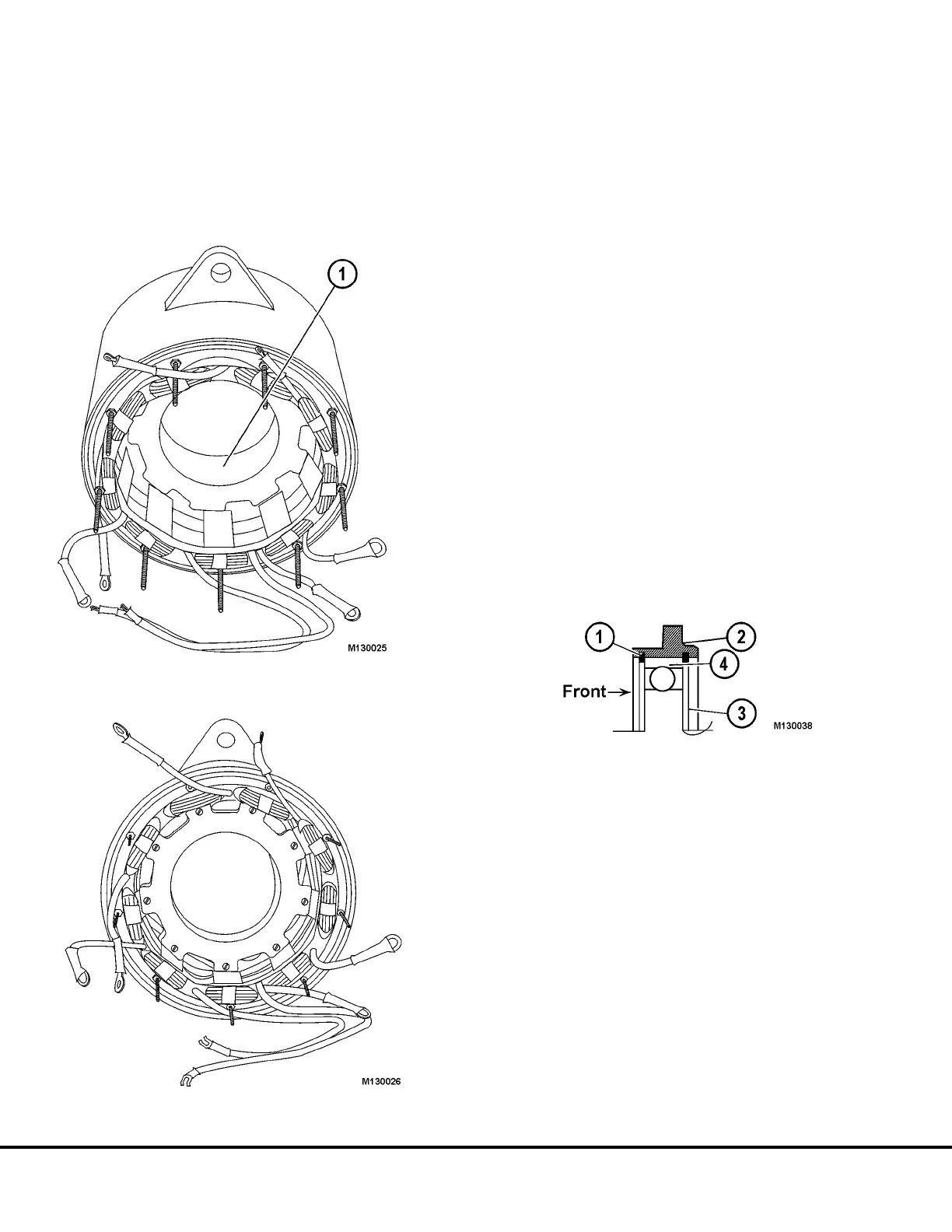

4. Seat field coil bobbin ears over stator tabs (Figure

13-21) by inserting field winding and rotating

about 20 degrees after insertion with tool BF4820.

Align screw holes in bobbin ears with screw holes

in stator tabs.

Note: Bobbin ears go over stator tabs as viewed from

both ends of tube assembly.

5. Make sure field coil leads (white spade terminals)

are pulled through proper stator openings with no

slack at the field coil and that neither wire is

pinched by the bobbin ears.

6. Using eighteen screws coated with loctite, fasten

field coil bobbin ears to stator tabs (Figure 13-22).

Tighten screws to 8-10 lb-in. (0.9- 1.1 Nm) torque.

Note: If field coil leads cannot be threaded through

stator openings with the terminal attached, unsolder

terminals, remove sleeving and then insert leads. After

field coil is in place slip sleeving on field leads, resolder

terminals to wires and slip sleeving back over terminal.

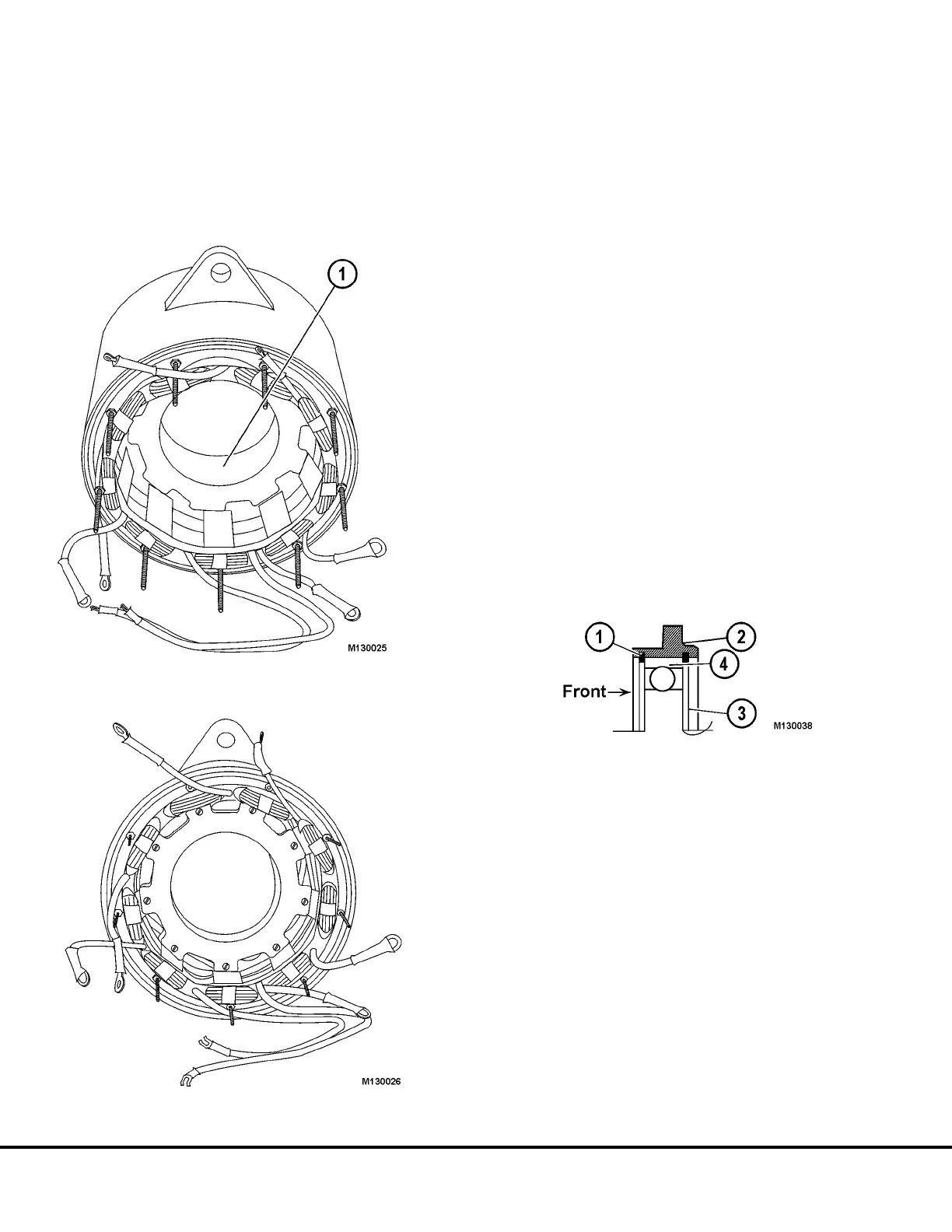

FRONT BEARING ASSEMBLY

1. Clean bearing I.D. surface of front housing.

2. Install retaining ring in rear inner groove of front

housing.

Note:

This retaining ring has two flat sides (3, Figure 13-23).

3. Coat outer race of front bearing (4, Figure 13-23)

with thin coat of loctite.

FIGURE 13-21.

1. Field Coil Bobbin Ear

FIGURE 13-22.

FIGURE 13-23.

1. Retaining Ring (Tapered)

2. Front Housing

3. Retaining Ring (Flat, both sides)

4. Bearing - Outer Race

M13-18 Niehoff Alternator Overhaul Manual M13003 04/01

Loading...

Loading...