Chapter 6 - Parameter Description [FU2]

6-30

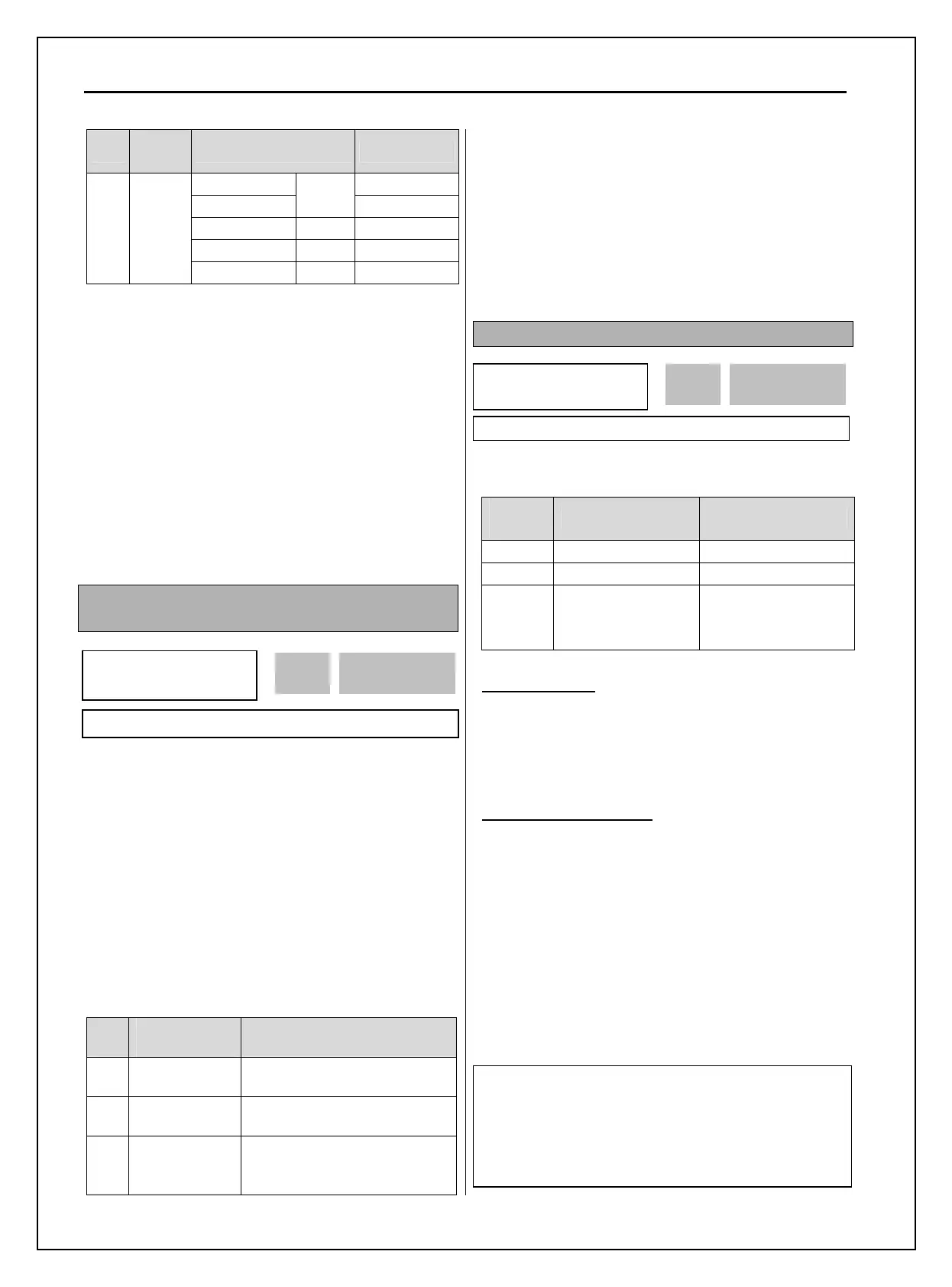

Code

LCD

Display

Factory Default Setting range

5.5 ~ 22 kW 0.7 ~ 15 [kHz]

30 kW

5 [kHz]

0.7 ~ 10 [kHz]

37 ~ 75 kW 4 [kHz] 0.7 ~ 4 [kHz]

90 ~ 280 kW 3 [kHz] 0.7 ~ 3 [kHz]

FU2-

48

Carrier

freq

315 ~ 450 kW 2 [kHz] 0.7 ~ 2 [kHz]

This parameter affects the audible sound of the motor,

noise emission from the inverter, inverter

termperature, and leakage current. If the ambient

temperature where the inverter is installed is high or

other equipment may be affected by potential inverter

noise, set this value lower. If set above 10kHz,

reduce the rated current by 5% per 1kHz. Setting

Carrier freqeuncy set below 1.5 [kHz] when the FU2-

60 [Control mode selection] is set to Sensorless, the

control performance could be weaken.

☞ Caution: FU2-48 [Carrier freq] setting range

varies as inverter capacity.

FU2-49: PWM Mode Selection (to reduce noise or

leakage current by changing PWM method)

Noise and leakage current can be reduced without

changing carrier freqeuncy by decreasing switching

cycle.

“Normal 1” is the general PWM method while

“Normal 2” is the PWM method when low noise (low

motor sound) is needed at motor starting. When

Normal 1 is selected at motor starting, inverter

changes switching frequency from low to set value.

When Normal 2 is selected, inverter starts to operate

at the set-value. “Low Leakage” is used to reduce

Leakage current by decreasing switching cycle.

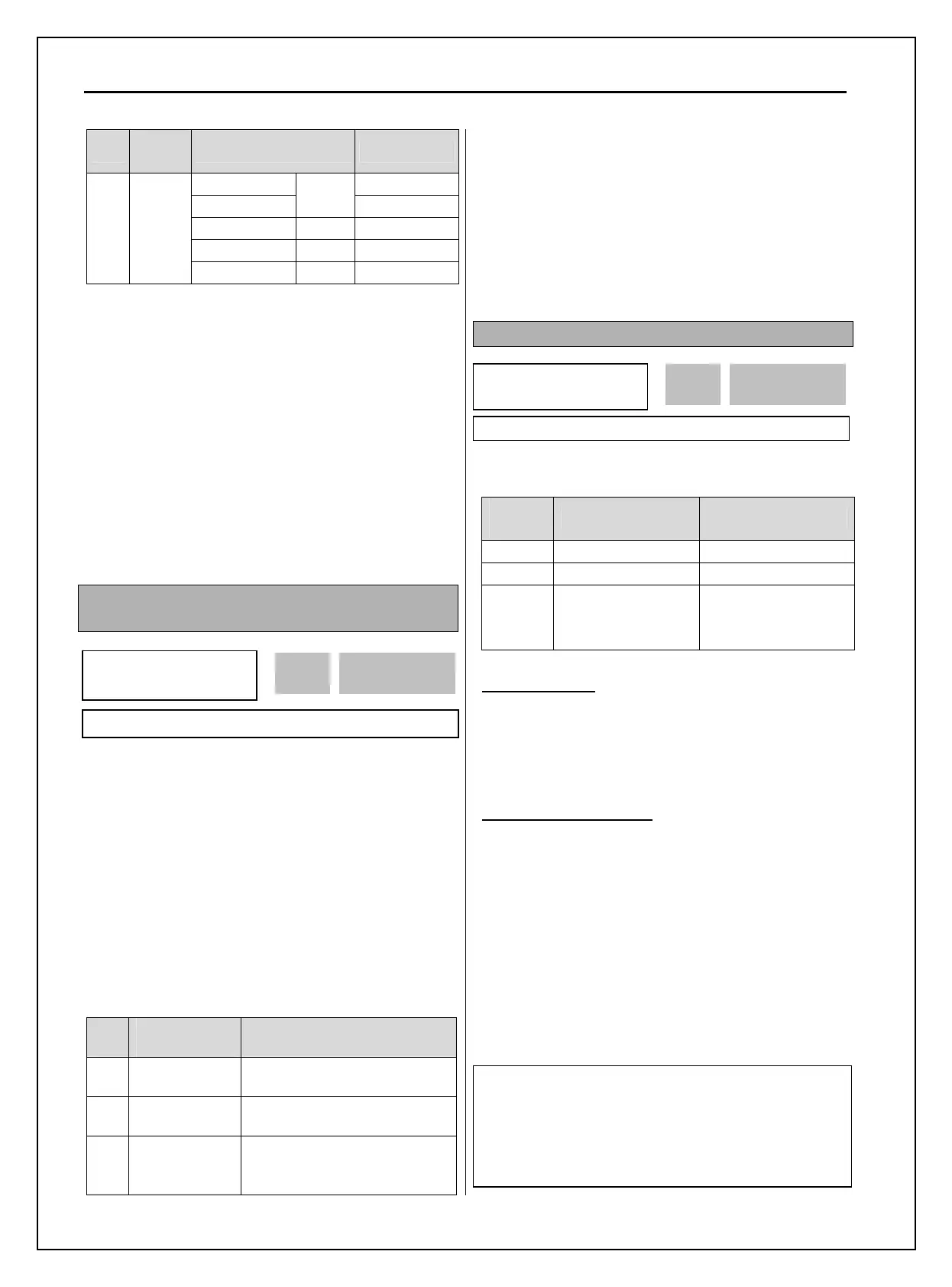

No

I/O-86,-87,-

88 setting

Description

0 Normal 1

Operation via basic

Carrier(switching) frequency.

1 Normal 2

Operation via fixed

Carrier(switching) frequency.

2 Low Leakage

Change (Carrier)switching

frequency pattern to reduce

leakage current.

☞ Caution: Reducing the Carrier frequency may

increase noise.

☞ Caution: When 2 {Low leakage} is selected

while carrier frequency is set lower than 2.0 kHz

in FU2-48, FU2-48 value is automatically set to

2.0kHz.

FU2-60: Control mode selection

Selects the control mode of the inverter

FU2-40

setting

LCD Display Description

0 V/F V/F Control

1 Slip compensation Slip compensation

2 Sensorless

Sensorless vector

control speed

operation

◈ V/F control:

This parameter controls the voltage/frequency ratio

constant. It is recommended to use the torque boost

function when a greater starting torque is required.

Related function: FU1-67~69 [Torque boost]

◈ Slip compensation:

This function is used to maintain constant motor

speed. To keep the motor speed constant, the output

frequency varies within the limit of slip frequency set

in FU2-42 according to the load current. For example,

when the motor speed decreases below the reference

speed (frequency) due to a heavy load, the inverter

increases the output frequency higher than the

reference frequency to increase the motor speed. The

inverter increases or decreases the output by delta

frequency shown below.

FU2

►

Control mode

60 V/F

0 60

Factory Default: V/F 0

Delta freq (Slip Comp. Freq.) = Motor Rated slip *

(Output current - Motor No load current) / (Motor rated

current - Motor No load current)

Output freq = Reference freq + Delta freq

FU2

► PWM Select

49 Normal 1

0 49

Factory Default: Normal 1 0

Loading...

Loading...