Chapter 6 - Parameter Description [I/O]

6-53

[PID operation selection], APP-80 [Ext. PID

operation selection] and APP-62 [PID Bypass

selection]. Then, set one of the desired unit among

Percent, Bar, mBar, kPa, and Pa in I/O-86, 86, 88. In

this case, all unit display related to inverter target

frequency are changed.

When APP-02 [PID operation selection], APP-80

[Ext. PID operation selection] and APP-62 [PID

Bypass selection] setting value is “0”, I/O-86, -87, -

88 are initialized to Speed [Hz]. If DRV-16 is

changed to [Rpm], unit display is changed from [Hz]

to [Rpm].

I/O-90, 91: Inverter Number, Baud Rate

I/O-92, 93: Operation method when

communication signal is lost, Communication

Time Out

I/O-94: Communication Delay Time

I/O-90 [Inverter Number] sets the inverter ID to

perform RS485 communication with PC. I/O-91

[Baud rate] sets the communication speed. To make

the multi-drop system, connect the terminal C+ to

other inverter’s C+ and C- to C-.

I/O-92, 93 are only displayed when DRV-03 [Drive

mode] or DRV-04 [Frequency mode] is set to 4 “Int.

485”.

In this case, the LCD display shows “LOR”.

I/O-93 [Communication time out] determines

whether the signal is lost.

Three types of operating method described on the

table below are settable after loss of communication

signal.

Setting Range Description

None

Continuous operation after loss of

communication signal.

FreeRun

Inverter cuts off its output after

determining loss of communication

signal.

Stop

Inverter stops by its Decel pattern and

Decel time after determining

communication signal.

I/O-94 setting is for communication using 232-485

converter. It should be set properly according to 232-

485 converter specification.

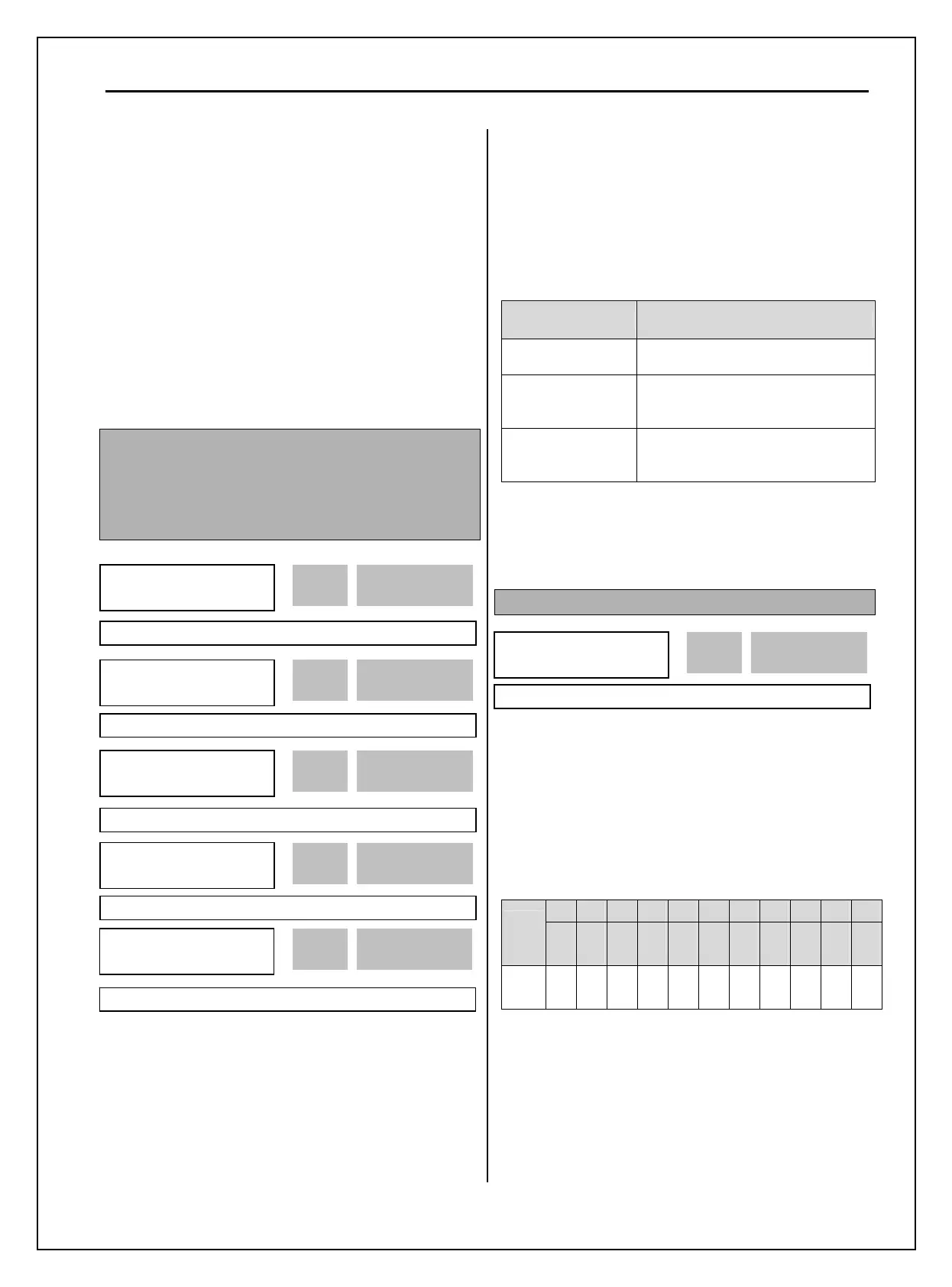

I/O-95: Normal Open/ Normal Close select

The input contact logic (Normal Open-A

Contact/Normal Close-B Contact) for M1, M2, M3,

M4, M5, M6, M7, M8, P4, P5 and P6 can be

programmed in this code. P4, P5 and P6 are settable

only with Sub-board installed.

[LCD KEYPAD DISPLAY]

P6 P5 P4 M8 M7 M6 M5 M4 M3 M2 M1

Input

T/M

10

bit

9

bit

8

bit

7

bit

6

bit

5

bit

4

bit

3

bit

2

bit

1

bit

0

bit

0: NO

1: NC

0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1 0/1

I/O►

COM Lost Cmd

92 None

0 92

Factory Default: None 0

I/O►

COM Time Out

93 1.0 sec

1.0 93

Factory Default: 1.0 sec 1.0

I/O►

In No/NC Set

95 00000000000

0000

95

Factory Default: 00000000000 0000

I/O►

Inv No.

90 1

1 90

Factory Default: 1 1

I/O►

Baud rate

91 9600 bps

3 91

Factory Default: 9600 bps 3

I/O►

Delay Time

94 5

5 94

Factory Default: 5 ms 5

Loading...

Loading...