Chapter 6 - Parameter Description [APP]

6-62

This is the frequency upper limit at which the output

frequency is limited during PID control.

This is the frequency lower limit at which the output

frequency is limited during PID control.

APP-12: PID Output Scale

APP-13: PID P2 Gain

APP-14: P Gain Scale

This code sets the scale of PID controller output.

This code sets the second P-Gain for PID control.

This code sets the conversion scale of P-Gain and P2-

Gain.

APP–15 [Output inversion] sets PID controller’s

output inversion.

This code is useful for fan and pumps application. It

converts linear pattern of a feedback sensor to the

squared pattern without any setting.

PID output value can be set to ‘0’ by setting a

Programmable digital input terminals (M1 ~ M8) to

‘Open loop’ in I/O- I/O-20 ~ I/O-27.

The accumulated value by I-Gain can be set to ‘0’ by

setting a Programmable digital input terminal (M1 ~

M8) to ‘iTerm Clear’ in I/O-20 ~ I/O-27.

The P-Gain 2 can be selected for PID controller by

setting a Programmable digital input (I/O-20 ~ I/O-

27) to ‘Open-loop’.

When APP-02 [PID operation selection] is set to

“Yes,” a desired display unit in I/O-86, -87, -88 [User

Unit selection] is set among Speed, Percent, Bar,

mBar, kPa, Pa, which affects value display of APP-

06[PID feedback selection], all the parameter unit

related to inverter target frequency is changed.

APP-20 ~ APP-29: 2

nd

Functions

These functions are displayed only when one of the

multifunction inputs in codes I/O-20 to I/O-27 is set

at ‘2nd func’.

When an inverter is controlling two motors by

exchanging, different values can be set for the 2

nd

motor by using the multifunction input terminal.

Following a cross reference table shows the 2

nd

functions corresponding to the 1

st

functions.

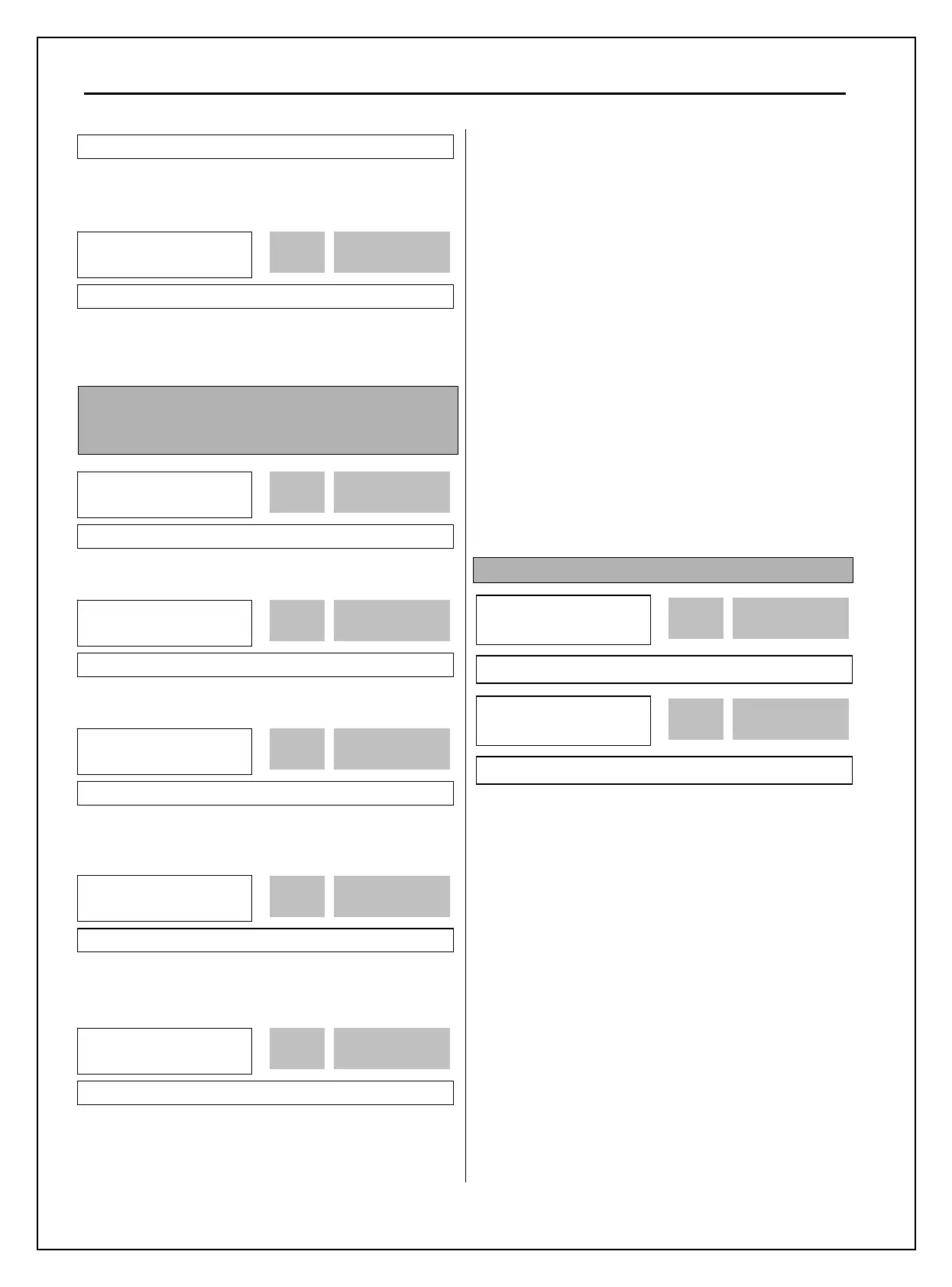

Factory Default: 60.00 Hz 60.00

APP

►

PID limit-L

11 0.5 Hz

0.5 11

Factory Default: 0.5 Hz 0.5

APP

►PID Out Scale

12 100.0 %

100.0 12

Factory Default: 100.0 % 100.0

APP

► PID P2-gain

13 100.0 %

100.0 13

Factory Default: 100.0 % 100.0

APP

►P-gain Scale

14 100.0 %

100.0 14

Factory Default: 100.0 % 100.0

APP

► PID U Fbk

17 No

0 17

Factory Default: NO 0

APP

► PID Out Inv.

15 No

0 15

Factory Default: No 0

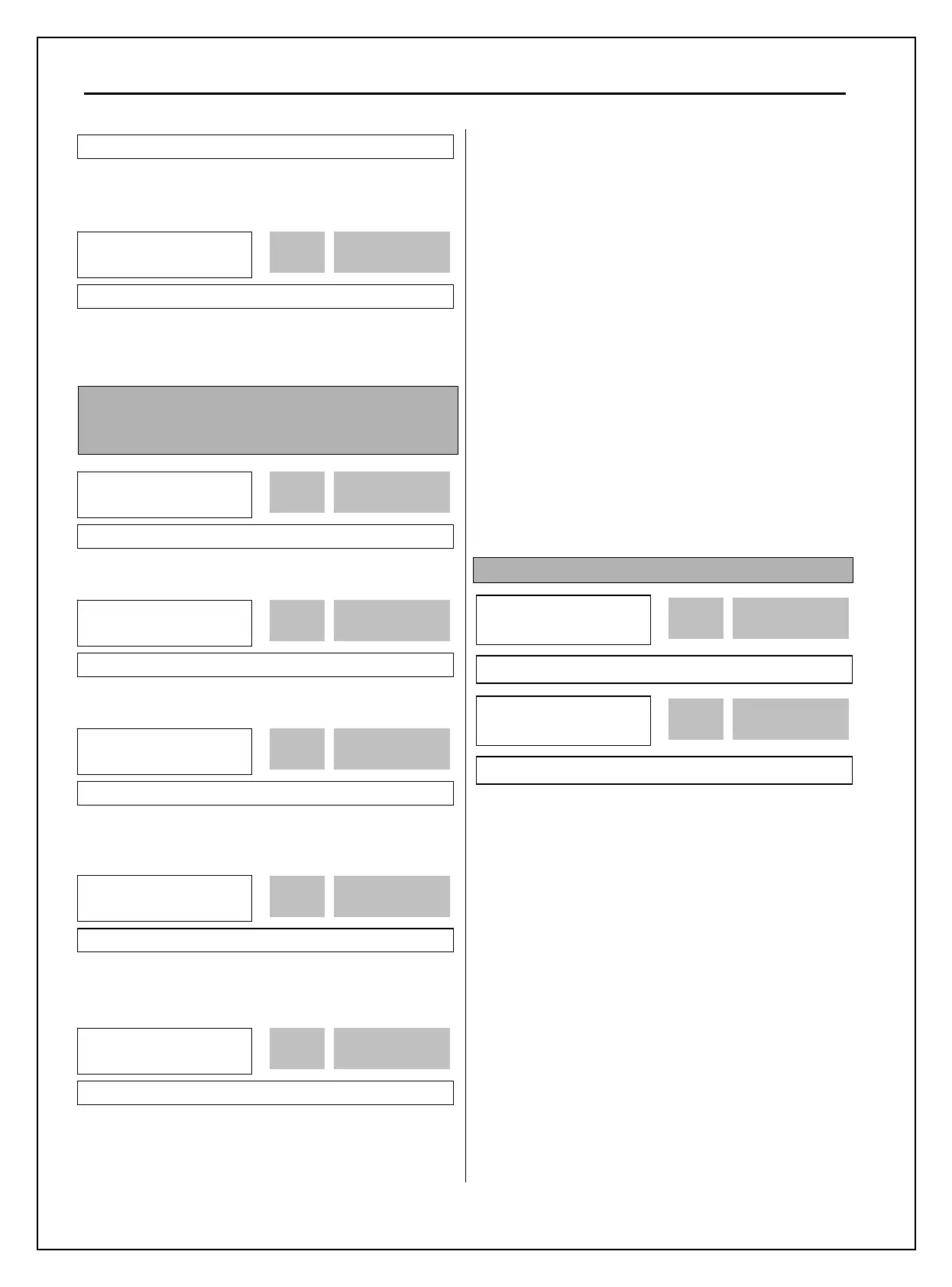

APP

►

2

nd

Acc time

20 5.0 sec

5.0 20

Factory Default: 5.0 sec 5.0

APP

►

2

nd

Dec time

21 10.0 sec

10.0 21

Factory Default: 10.0 sec 10.0

Loading...

Loading...