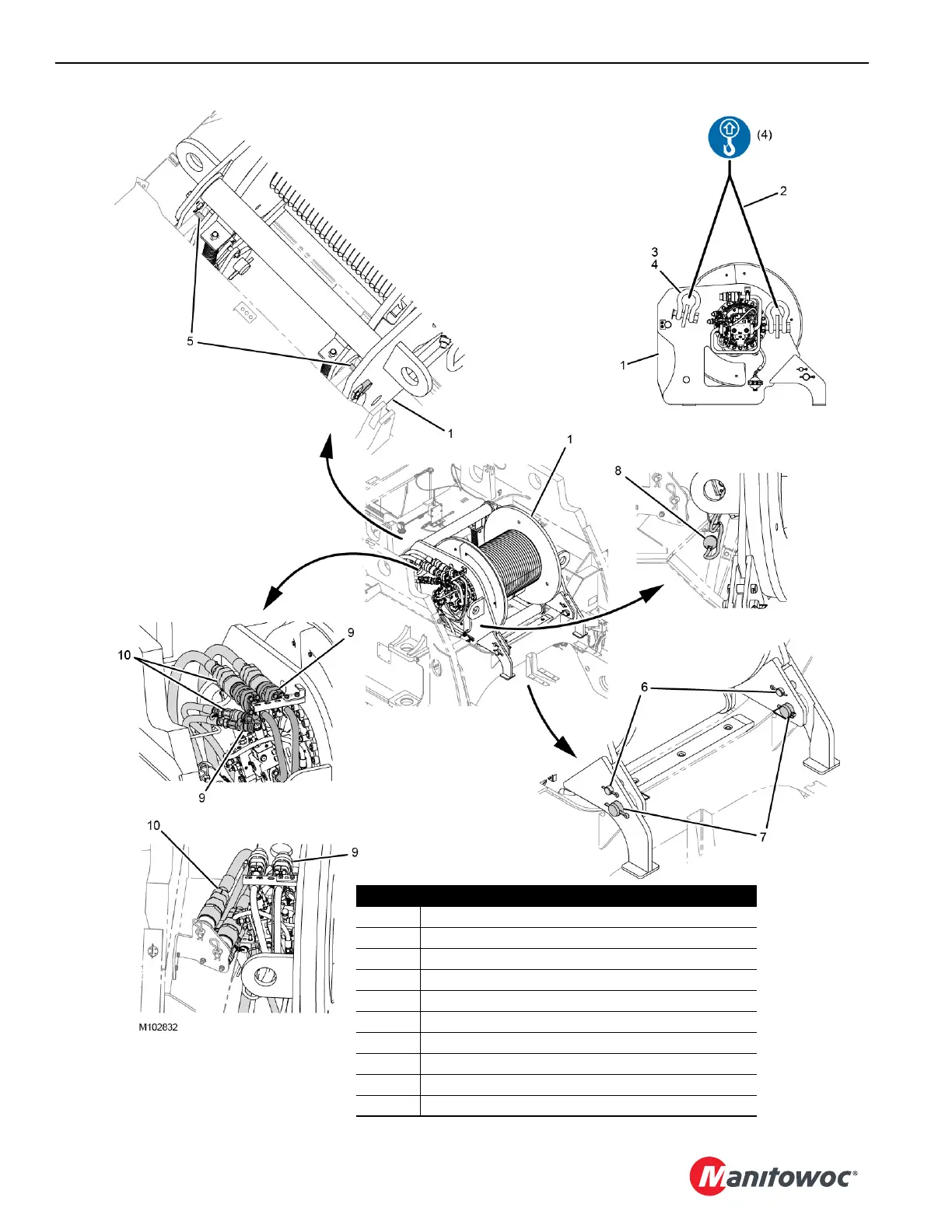

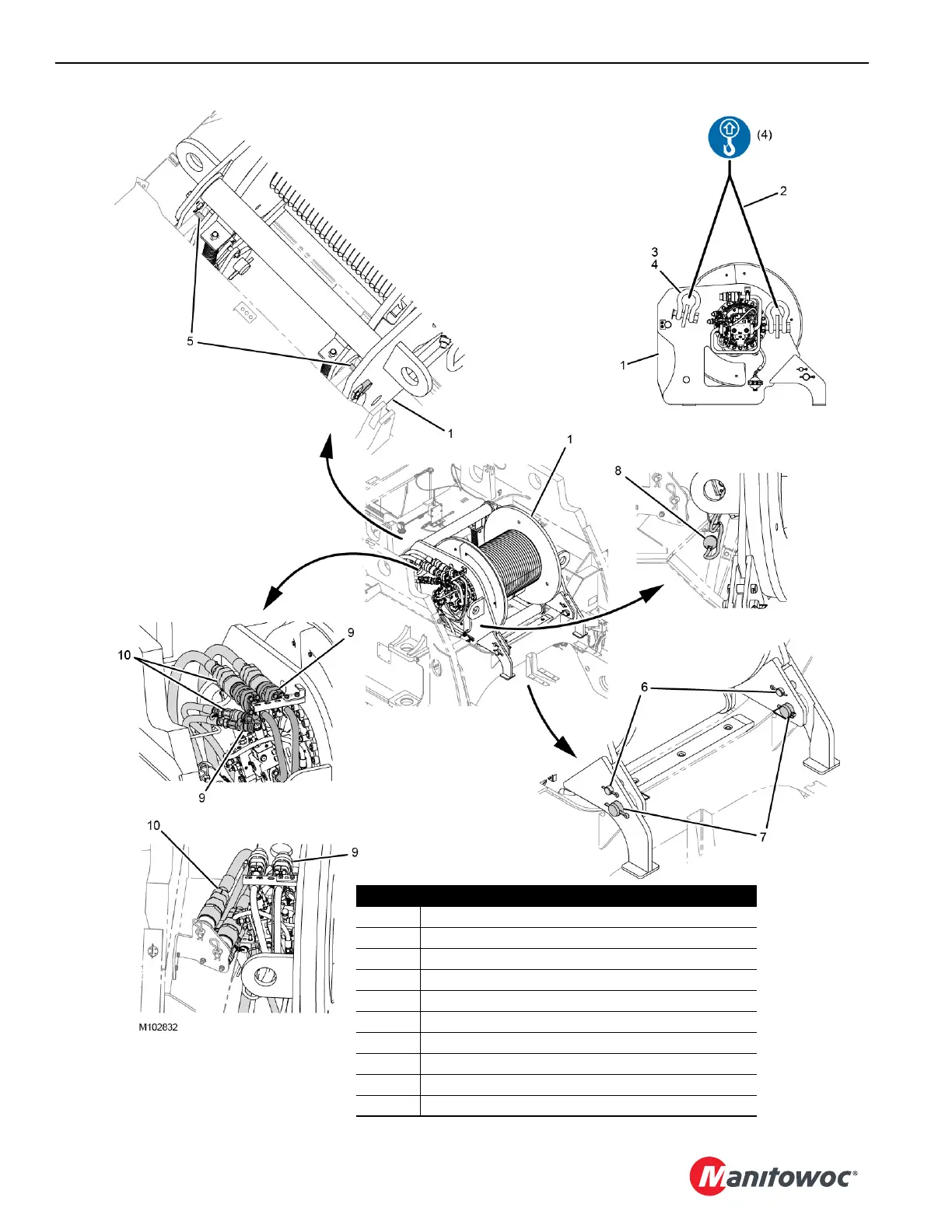

FIGURE 4-26

View A

WORKING POSITION

STORED POSITION

Item Description

1 Drum 3 Assembly

24-SL 4 - Slings - 3,80 m (12.5 ft) - 11 340 kg (25,000 lb)

3 Lifting Lug (4)

44-SH 2 - Shackles - 17 t (18.70 USt)

5 Rear Pins

6 Front Pins

7 Pins with Safety Pins (qty 2)

8 Electric Cable (WRF1-P1)

9 Hydraulic Couplers (qty 4)

10 Hydraulic Hoses (qty 4)

Loading...

Loading...