NXP Semiconductors

UM11227

NTM88 family of tire pressure monitor sensors

UM11227 All information provided in this document is subject to legal disclaimers. © NXP B.V. 2020. All rights reserved.

User manual Rev. 6 — 24 April 2020

142 / 205

ADC trigger, then a timer such as FRC, PWU, or RTI has to be set to generate the wake

up, followed by the ADC trigger in the run mode. The ADC will subsequently generate

the COCO signal and, if enabled, its associated interrupt. Note in all cases, the ADC

COCO bit will be cleared upon the ADC interrupt service routine reading the ADCRES

Low register.

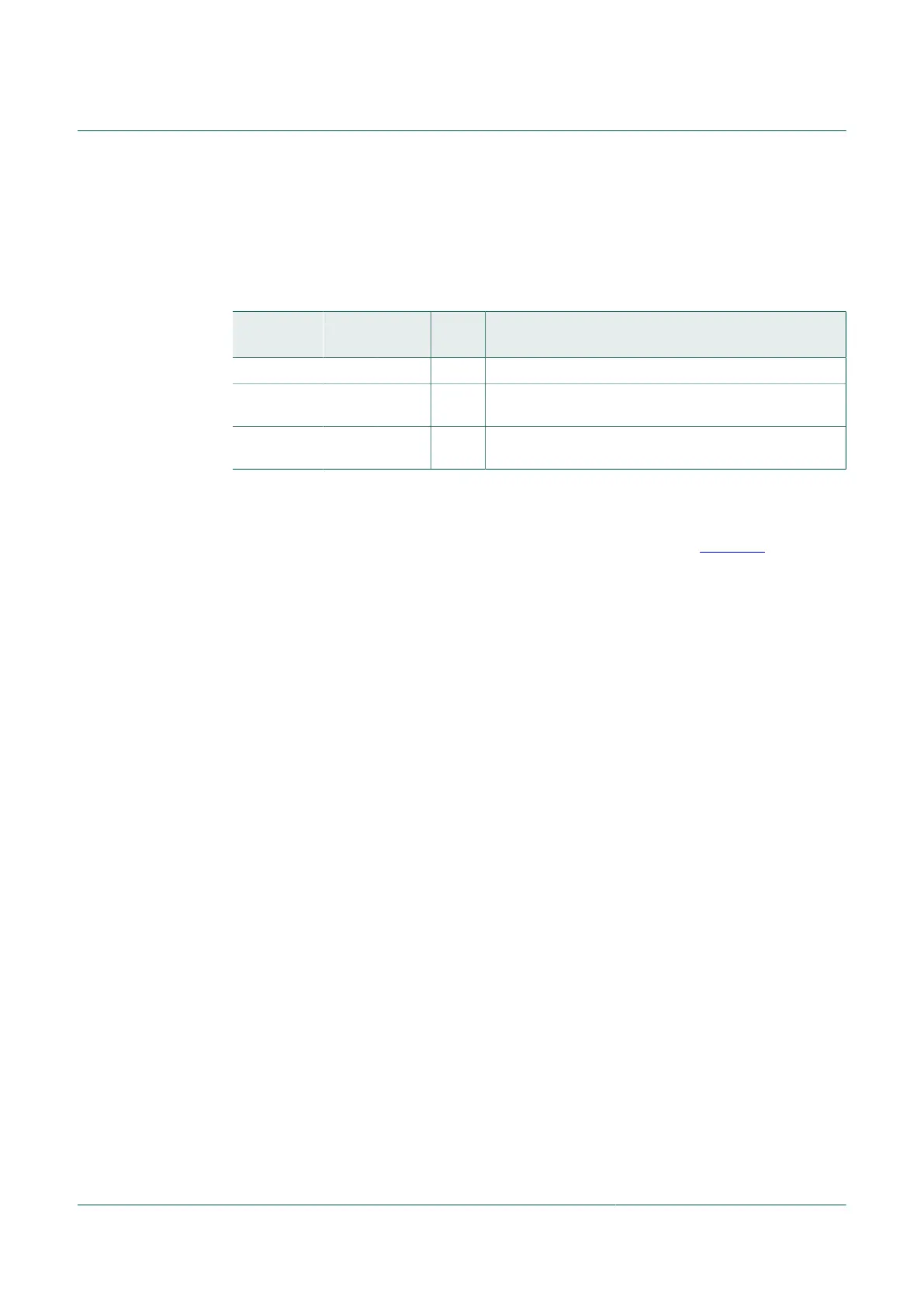

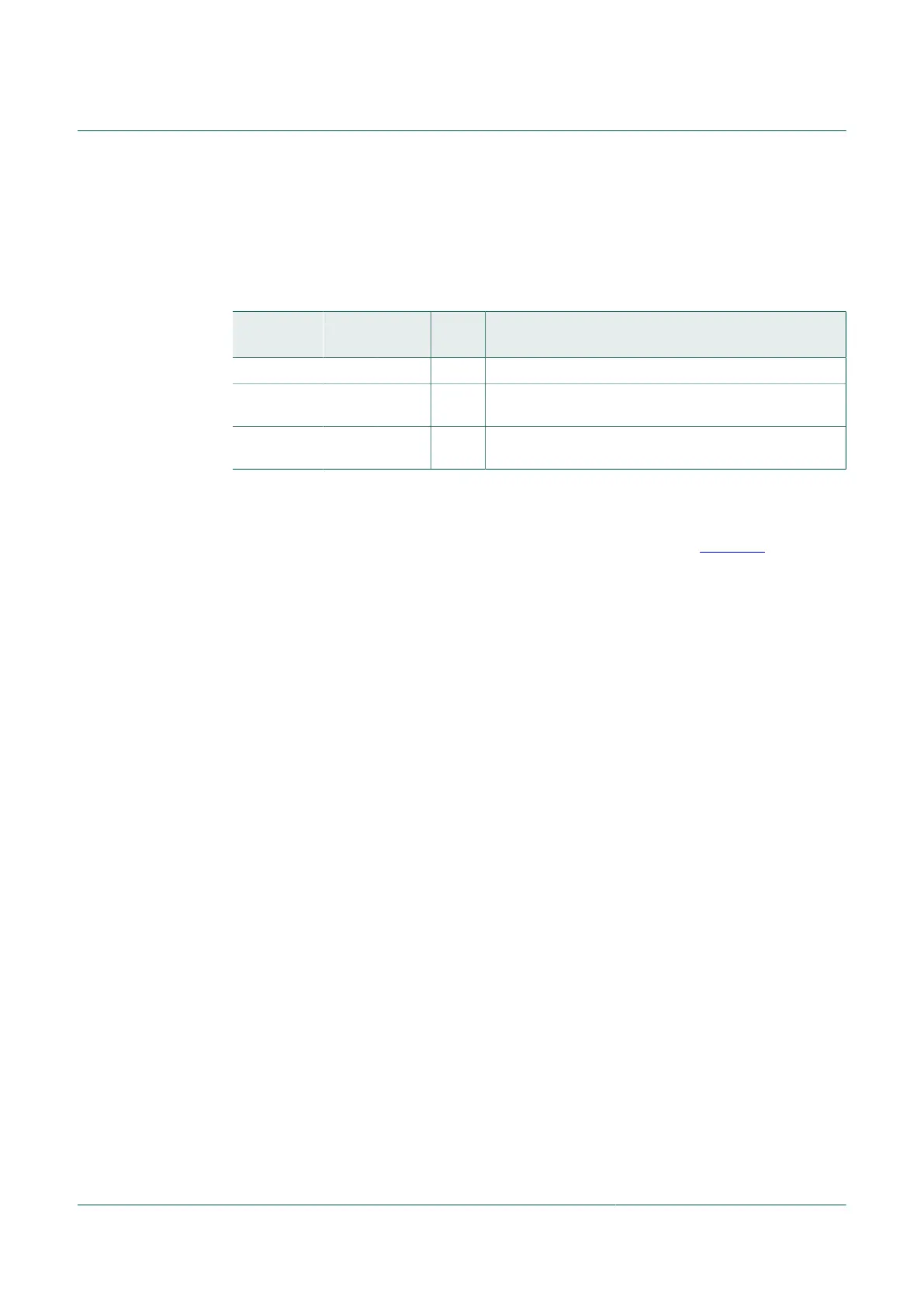

Table 145. Signal measurement sub-modes

SMI

Sub-mode

MCU

RUN

MCU

STOP4

MCU

STOP1

Comments

Automatic Yes Yes No SMI terminated after a single measurement.

Direct Yes No No SMI signal chain runs continuously, measurements are

triggered by the MCU. Stop4 entry not recommended.

LPD Yes Yes No SMI signal chain runs continuously, measurements are

repeatedly triggered automatically by the hardware.

10.19.1.1 SMI automatic signal measurement mode

In the automatic mode of operation the sensor signal measurement is triggered by setting

the SEN bit (SMICS[4]) which generates a series of signals given in Figure 45.

The typical sensor measurement software sequence would be to first select the SMI

ADC multiplexer channel, select the SMI transducer channel, filter, and Initial Settling

Delay, then set the SEN bit, then poll the SEN bit to be sure it is set, and then go into the

STOP4 mode.

When the measurement is initialized and the sample delay is completed, the ADC

Trigger signal is generated. When ADC finishes a conversion, the ADC_COCO interrupt

will wake up the MCU, and the converted result will be available at the ADCRES H/L

registers. After the ADC conversion, the SEN bit (SMICS[4]) will be cleared, which in turn

powers down the transducer (g-cell or p-cell), and the software can then use the resulting

ADC data as desired. As mentioned, this must be completed within the period noted as

t

FIN

. Once the t

FIN

has completed, the software may then initiate a new measurement

cycle by setting the SEN bit, polling the SEN bit to be sure it is set, then entering the

STOP4 mode.

Notice in this configuration that the SEN bit will be automatically cleared by the

internal signal SFO being low or cleared. Then the internal signal CLR_SEN_SYNC

signifies that the SEN signal may be written for the next measurement cycle. Since

the CLR_SEN_SYNC signal is not available for the software to access, the software

has to poll the SEN bit until it is clear, then wait for a sufficient delay time for the

CLR_SEN_SYNC to clear. Since the ADC interrupt service routine will be short, the delay

while the SEN bit is clear is recommended to be the sum of the periods t

S4WU

+ t

FIN

.

Please review the corresponding data sheet for the periods noted as t

INIT

, t

MEAS

, T

ADC

,

t

S4WU

, and t

FIN.

In this configuration, the SMIF bit (SMICS[7]) is not available.

Loading...

Loading...