ECODRIVE03 Drive Controllers ECODRIVE03 DKC**.040, DKC**.100, DKC**.200 4-15

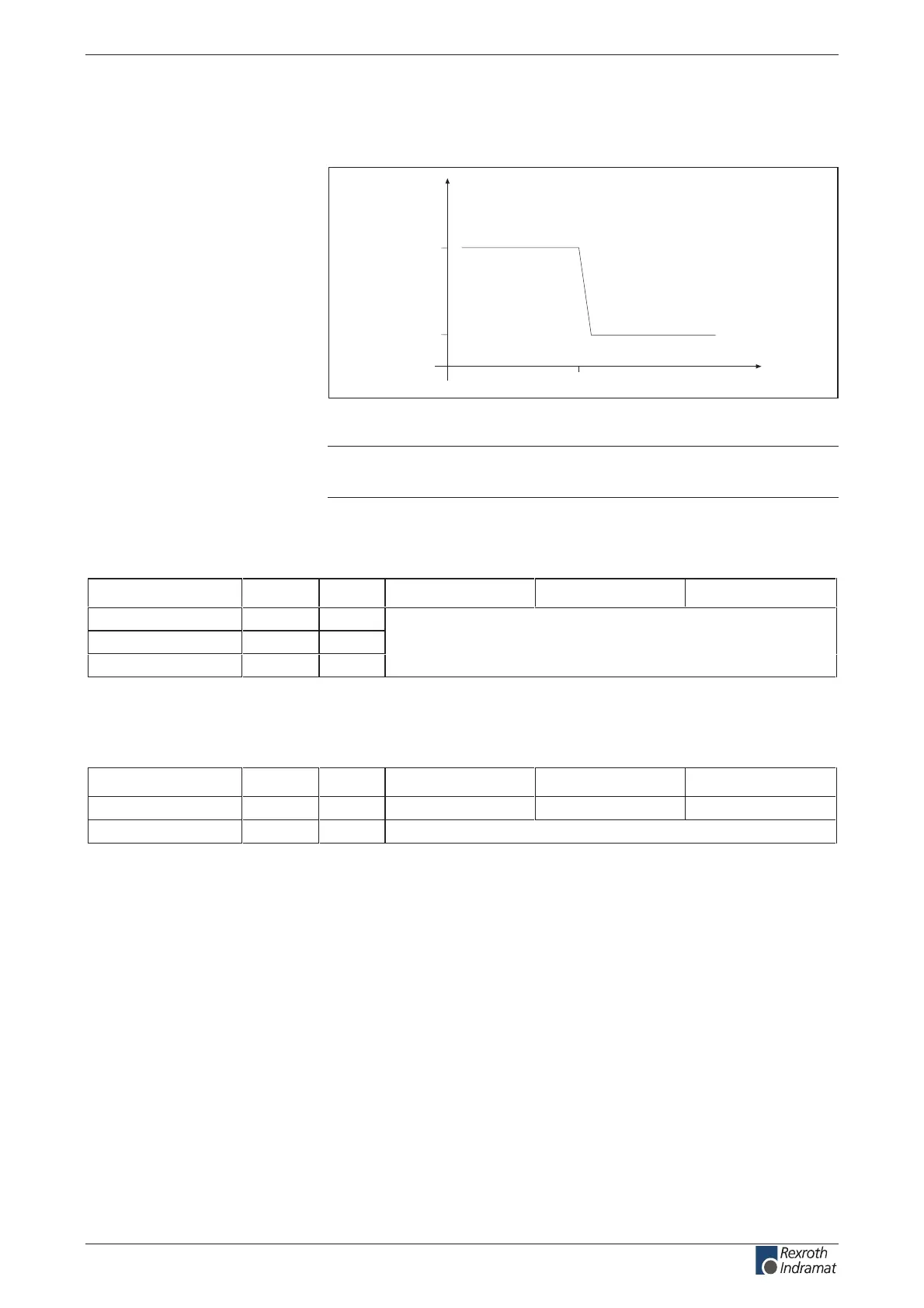

Amplitude of the DKC control voltage charging current at

startup, to selecting power source

time

current

I

EIN3

I

Nenn

t

N3Lade

Fig. 4-13: Example of charging current inrush of control voltage

Note: For n parallel-switched inputs the charging current inrush is

n-fold.

Voltage connection for holding brake

Designation Symbol Unit DKC**.3-040-7-FW DKC**.3-100-7-FW DKC**.3-200-7-FW

Input voltage U

HB

V depends on motor type, listed in motor project planning manual

Ripple content w %

Current consumption I

HB

A

(see also page 4-67 X6, Motor temperature monitoring and holding

brakes)

Fig. 4-14: Voltage connection for holding brake

Materials used, Mass

Designation Symbol Unit DKC**.3-040-7-FW DKC**.3-100-7-FW DKC**.3-200-7-FW

5.917.97.5gkmssaM

enocilis dna sotsebsa fo eerFdesu slairetam

Fig. 4-15: Materials used, mass

customerservice@hyperdynesystems.com | (479) 422-0390

Loading...

Loading...