Part A - General information cobas p 512

1-22 Operator's Manual - Version 1.6 - 10/2015

1.6. Preconditions for scanning a barcode

In order for the system to process the sample tube, the barcode must be placed correctly on

the tube and it must be easily readable. Therefore there are basic prerequisites which must be

met.

1.6.1 Barcode quality, printing and labeling material

In general: The readability and first-read rate will improve with improved print quality.

Likewise, better print quality leads to a reduced risk of reading errors by the substitution of

another line-gap sequence. Good code quality is characterized by sharp black-white contrasts

(non-blurry edges), and by clean gaps which are not contaminated with small dots (e.g., from

sprayed toner). Moreover, the lines should not be interrupted by white spots, but should be

deep black. High-quality printing methods include:

• Laser and thermal printing

• Offset printing, gravure printing

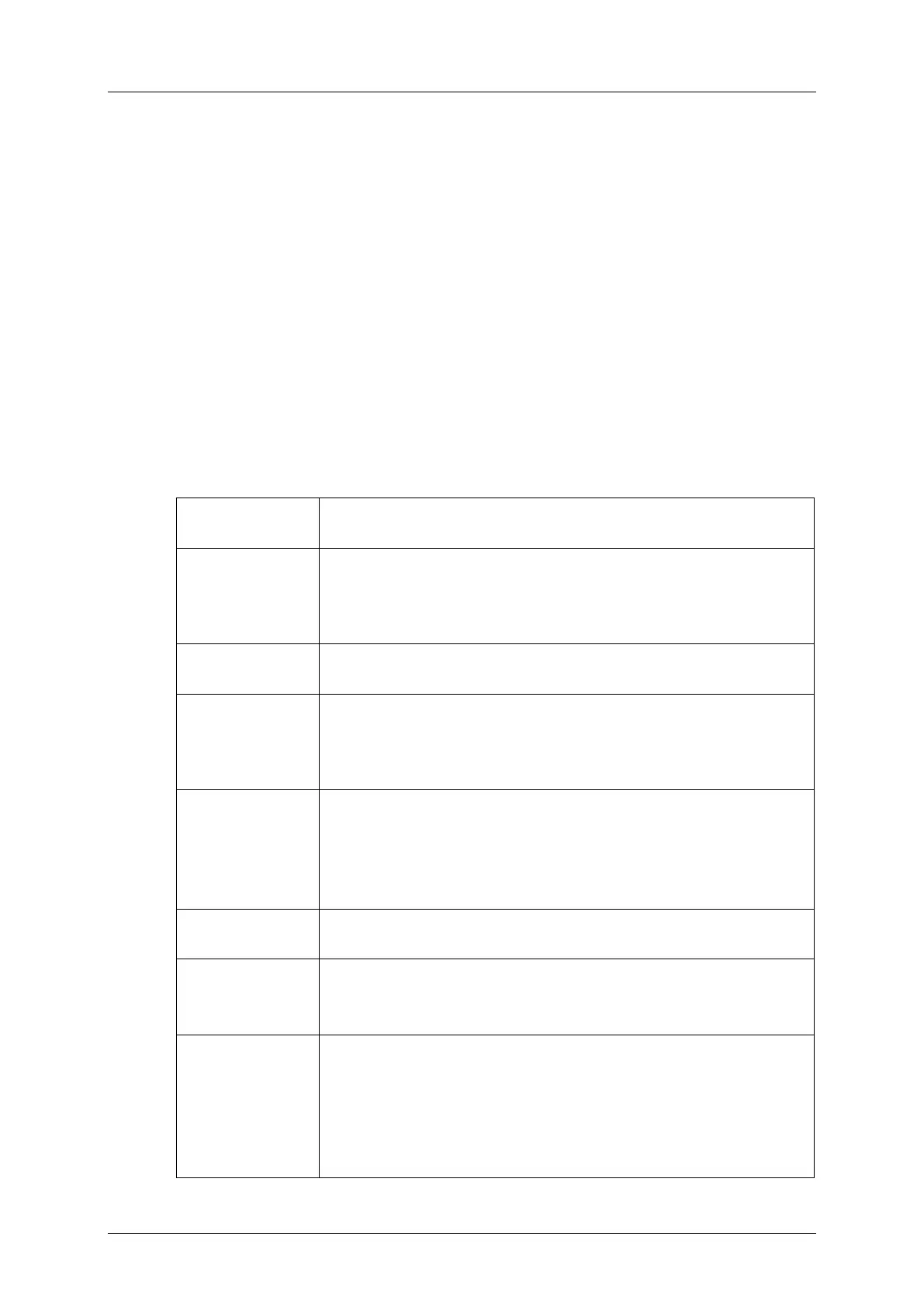

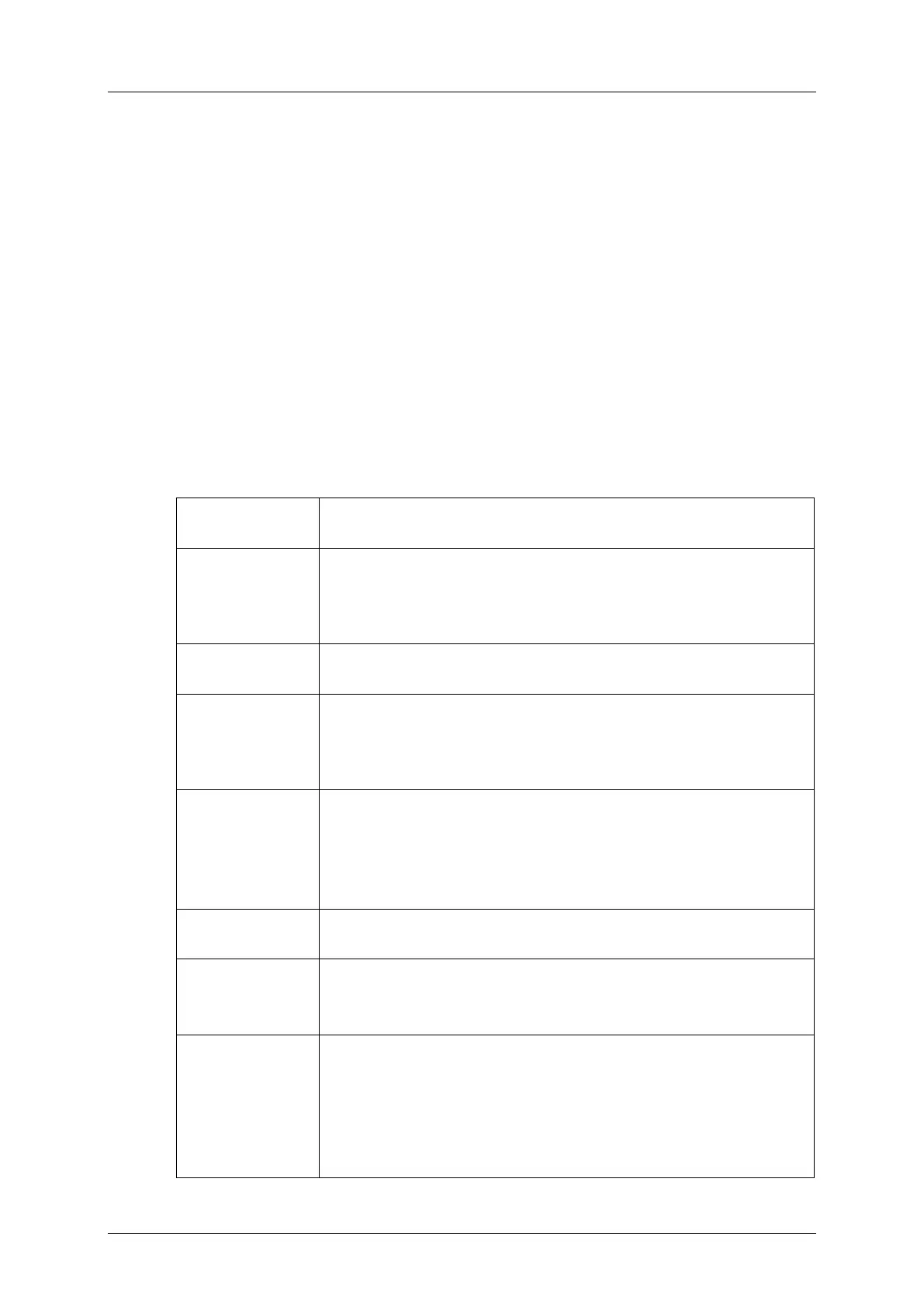

Quality of the

The ink for the barcodes should be coordinated with the PCS (print

PCS (Print

Contrast Signal)

The phrased used for the quality of a barcode related to the contrast

value of the barcode scanner. The value indicates the contrast

between the reflected signal of the empty white space and the

barcodes. It is expressed in percent.

Uniformity of the

Uniformity of printing ink in a barcode should be less than or equal

Contrast In order for a barcode to be detected, it is necessary to have a certain

contrast between the lines and gaps. With dark lines, you should use

only very bright paper or other data storage medium. The best

contrast is achieved with a black code on a white background.

Rest zone The white fields in front and behind of a barcode (the rest zone) are

very important and absolutely necessary for readability. Their

dimensions must be at least fifteen times larger that the module width

X. The module width X is the thinnest element in the barcode (a line

Check digit With poor-quality codes or printings, it is recommended to use a

barcode with a check digit.

White overflow The overflow is smaller when the barcode is smaller (thinner) and

further away.

The overflow is larger when the bars (columns) are wider and nearer.

Labeling material The barcodes should be printed on labels which fulfill the following

requirements:

• Only pure white barcode labels should be used.

• The outer side of the label must have a matt surface so that it

does not cause any reflections.

•

The labels must be smudge-proof.

Loading...

Loading...