Part B - System description cobas p 512

2-20 Operator's Manual - Version 1.6 - 10/2015

means of infrared light. It then transmits the upper and lower level of the respective sample

material to the system's control computer.

In the second step, the camera module determines the tube's type (and thus its dimensions)

via cap color identification. The system then calculates the respective volume of the tube's

content on the basis of this information.

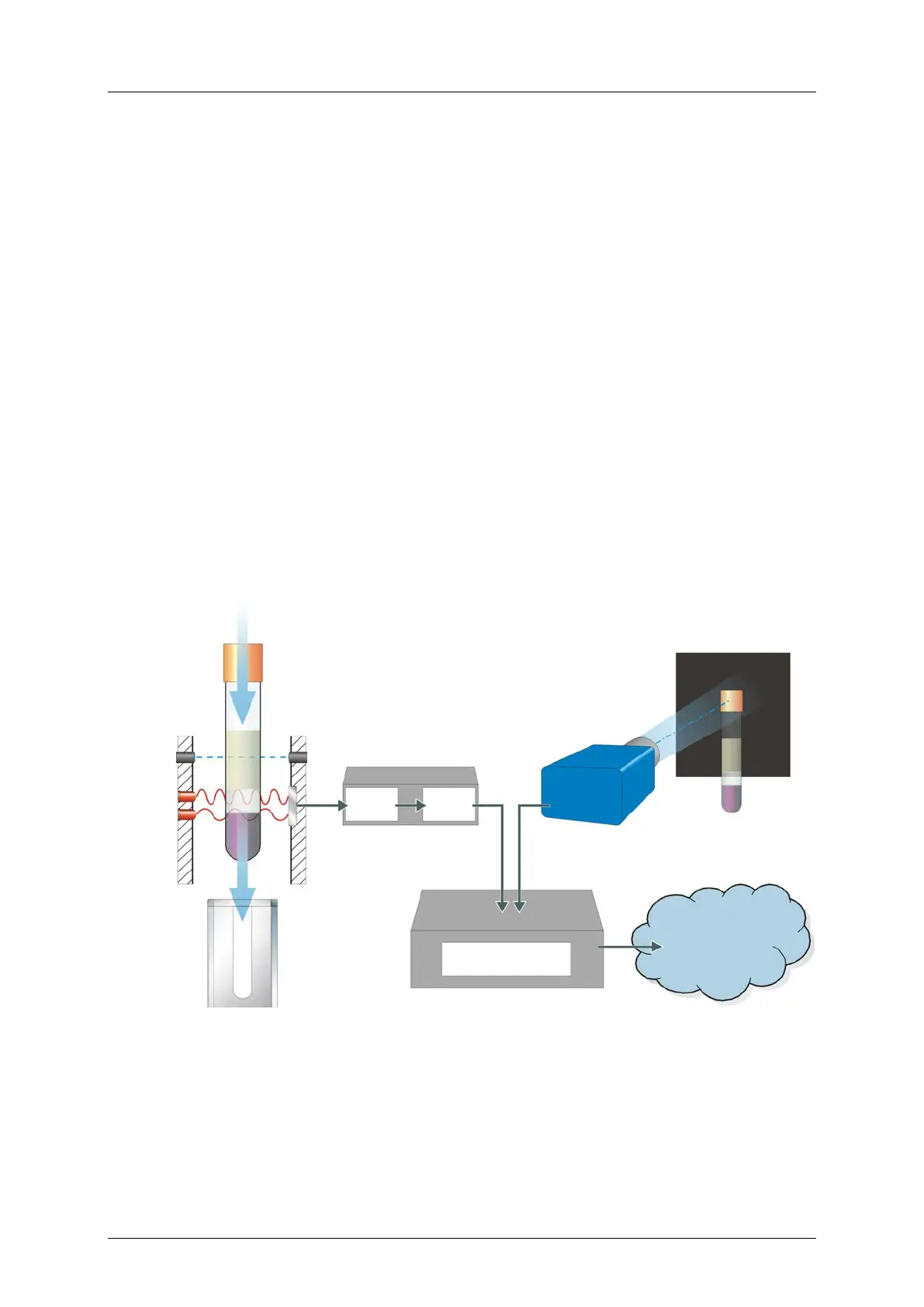

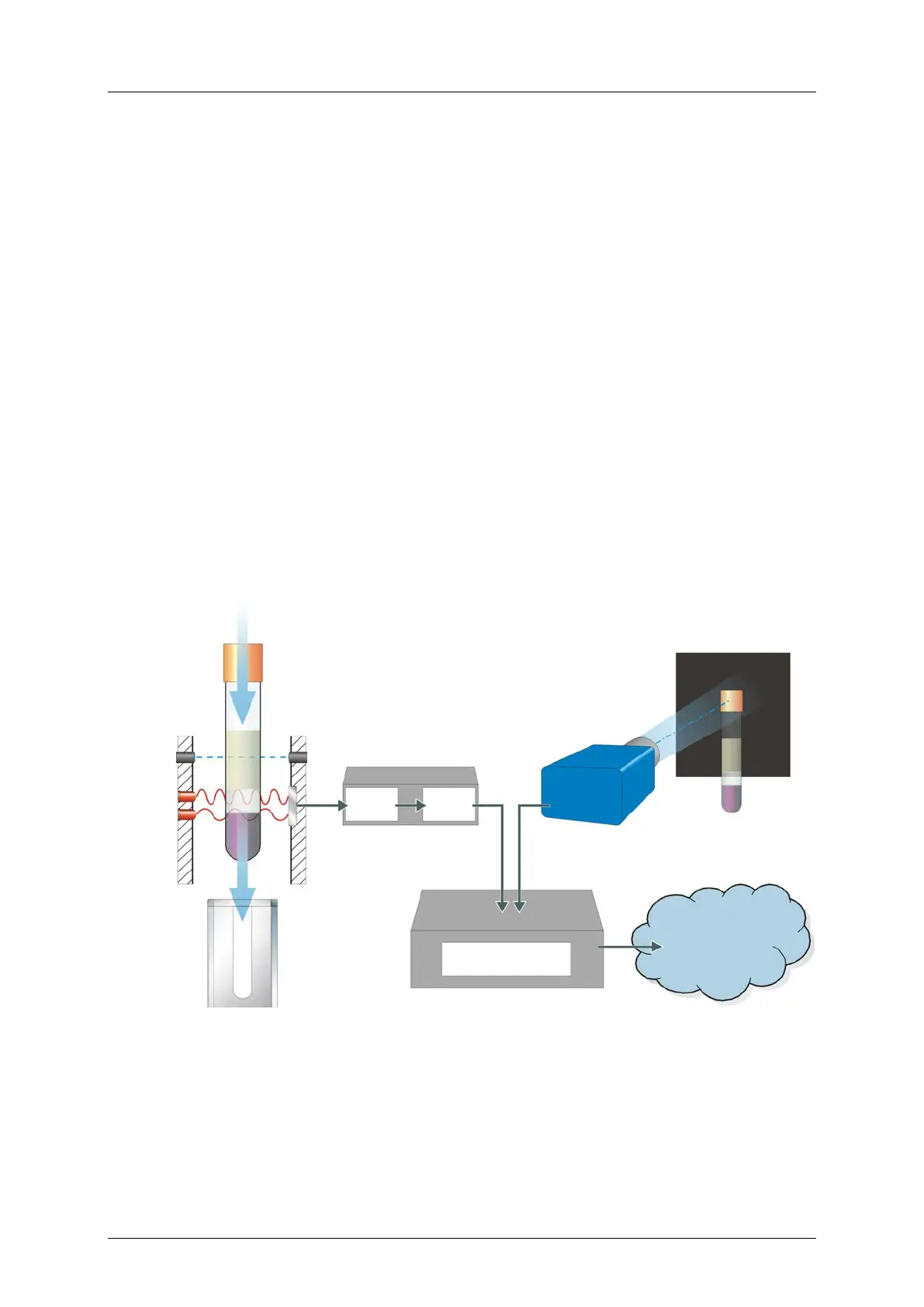

Measurement principle

An optical measuring procedure is used for determination of the material transitions within

the sample tube. This procedure works by two infrared emitters of different wavelength and a

receiver element sensitive for both wavelengths.

When starting the measurement, the emitters are pulsed by a microprocessor (µP) sending

the corresponding signals to a LED driver. Received signals from the sensor element are

supplied via an amplifier back to the microprocessor (µP) again. The availability of new

measuring data is then reported to the NetPC. Their transmission towards the NetPC is

initiated on request. Once the NetPC has evaluated the received measuring data, the results

are sent to the system's control computer.

In a second step, the system's camera module identifies the tube's type and thus determines

its dimensions. Both liquid level data and tube dimensions are then used to calculate the

volume of the sample material inside the tube.

The following schematic diagram provides an overview of the work steps described above:

Figure 2-15: Schematic diagram

camera (tube type identification module)

processor

control computer

Loading...

Loading...