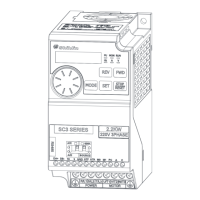

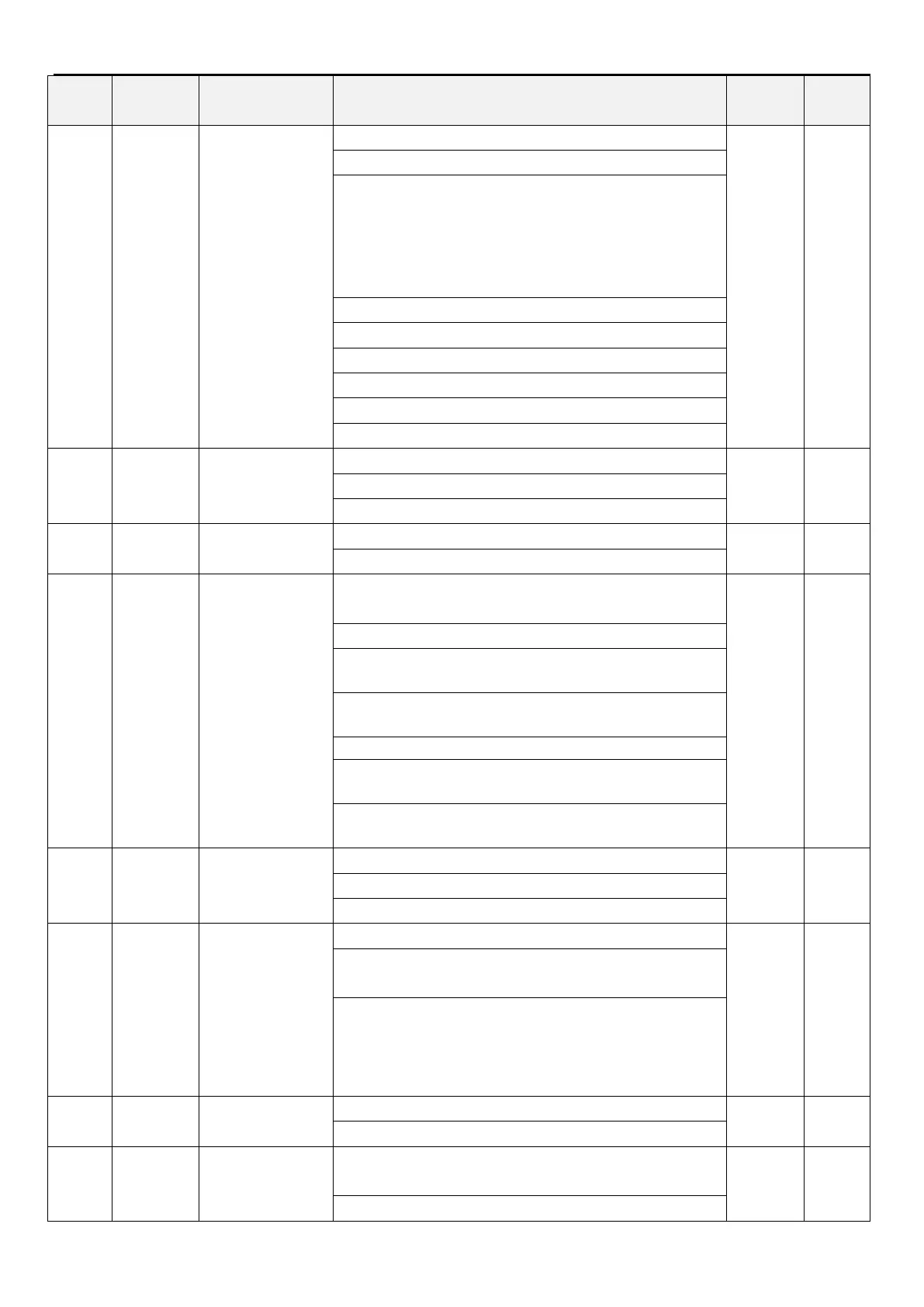

Appendix 1 Parameter table

Appendix 182

11: Forward reverse rotation signal.

Built-in keypad: Frd is forward,rEv is reverse,STOP is not

operating status.

External keypad:1 is forward , 2 is reverse, 0 is not operating

status..

13:Motor electronic thermal accumulation rate (%)

19: Digital terminal input state

20: Digital terminal output state

21: Actual working carrier frequency

0:Display output frequency(not mechanical speed)

Speed display unit

selection

0: Speed display unit is 1

1: Speed display unit is 0.1

Built-in keypad set

target frequency

selection

XXX0: Use wheel on built-in keypad or external keypad to set

frequency

XXX1: Use keypad knob on external keypad to set frequency

X0XX: Frequency change done and setting saves in 30

seconds

X1XX: Frequency change done and setting saves in 10

seconds

X2XX: Every frequency change will not save

0XXX: Set frequency will work immediately when use wheel

on built-in keypad

1XXX: Set frequency will work after pressing SET when use

wheel on built-in keypad

11K/15KF and below model:1~15kHz

15K/18.5KF and above Heavy Duty:1~15kHz

15K/18.5KF and above Normal Duty:1~10kHz

Soft-PWM carrier

function selection

1: When 00-11(P.72)<5,Soft-PWM is on(only apply to V/F

control)

2:When 00-11(P.72)>9, if the IGBT temperature is higher

than 60°c, carrier frequency will decrease automatically,

when temperature go back to under 40°c, carrier frequency

go back to 00-11(P.72) value.

0: Press STOP button and inverter stop running in PU and

H2 mode

1: Press STOP button and inverter stop running in all mode.

Loading...

Loading...