Installation and Circuitry

SICAM A8000 / CP-8000 • CP-8021 • CP-8022 Manual Unrestricted 197

DC8-037-2.02, Edition 10.2017

6.7.3 Process Peripherals

Cabinet-internal wiring is preferably carried out with plastic-insulated cables according to

DIN VDE 298 T4 2/89. Use only copper wires.

You can establish the connections with single leads of the type H05V-K or H05V2-K

(0.5…1 mm²), as well as H07V-K or H07V2-K (1.5…2.5 mm²).

Max. ambient temp. Max. operating temp. Type

55°C 70°C H05V-K, H07V-K

70°C 85°C H05V2-K, H07V2-K

• If a wire bridge with 0.75 mm² is used or a bridged comb, the cable cross section is limited

to 1.5 mm².

• The construction of the peripheral connectors is designed for direct peripheral wiring. That

means, that the wiring can be carried out without the use of a routing terminal or other ad-

ditional screw terminals.

• Removable screw terminals are used as peripheral connectors. These are attached to the

device for delivery. Optionally spring-loaded- or crimp terminals can be used.

• Preferably wire end sleeves are to be used.

• A cable duct is to be provided for the wiring of the process signals.

6.7.4 Shielding

CP-8000/CP-802x is designed in order that no shielded cables are necessary.

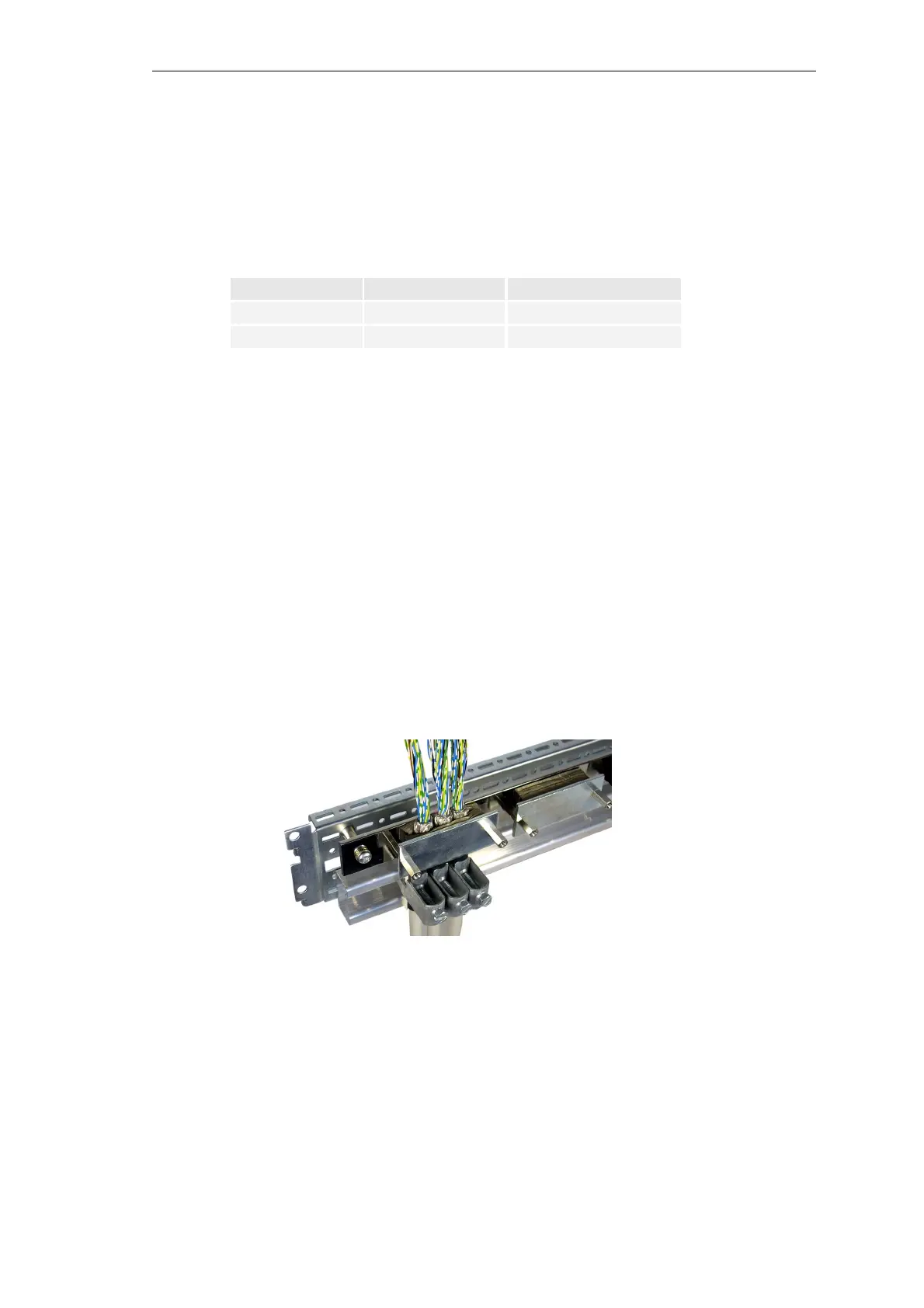

Normally, shielded cables are strain-relieved directly after the cabinet/rack entry and then

grounded on a large-surface screening rail installed for this purpose. The device itself pro-

vides no possibility of shield clamping.

6.7.5 Protective Earth/Ground

When installing CP-8000/CP-802x, it is to be ensured that the cabinet or rack used has proper

protective earth and ground. That means, that all electrical conducting parts must be

connected large-surface and as short as possible with the existing grounding system.

If these preconditions exist, the grounding of the device takes place via the connection of the

DIN rail with the cabinet spar. A reliable connection is achieved by using screws with contact

washers.

Loading...

Loading...