System Overview

54 Unrestricted SICAM A8000 / CP-8000 • CP-8021 • CP-8022 Manual

DC8-037-2.02, Edition 10.2017

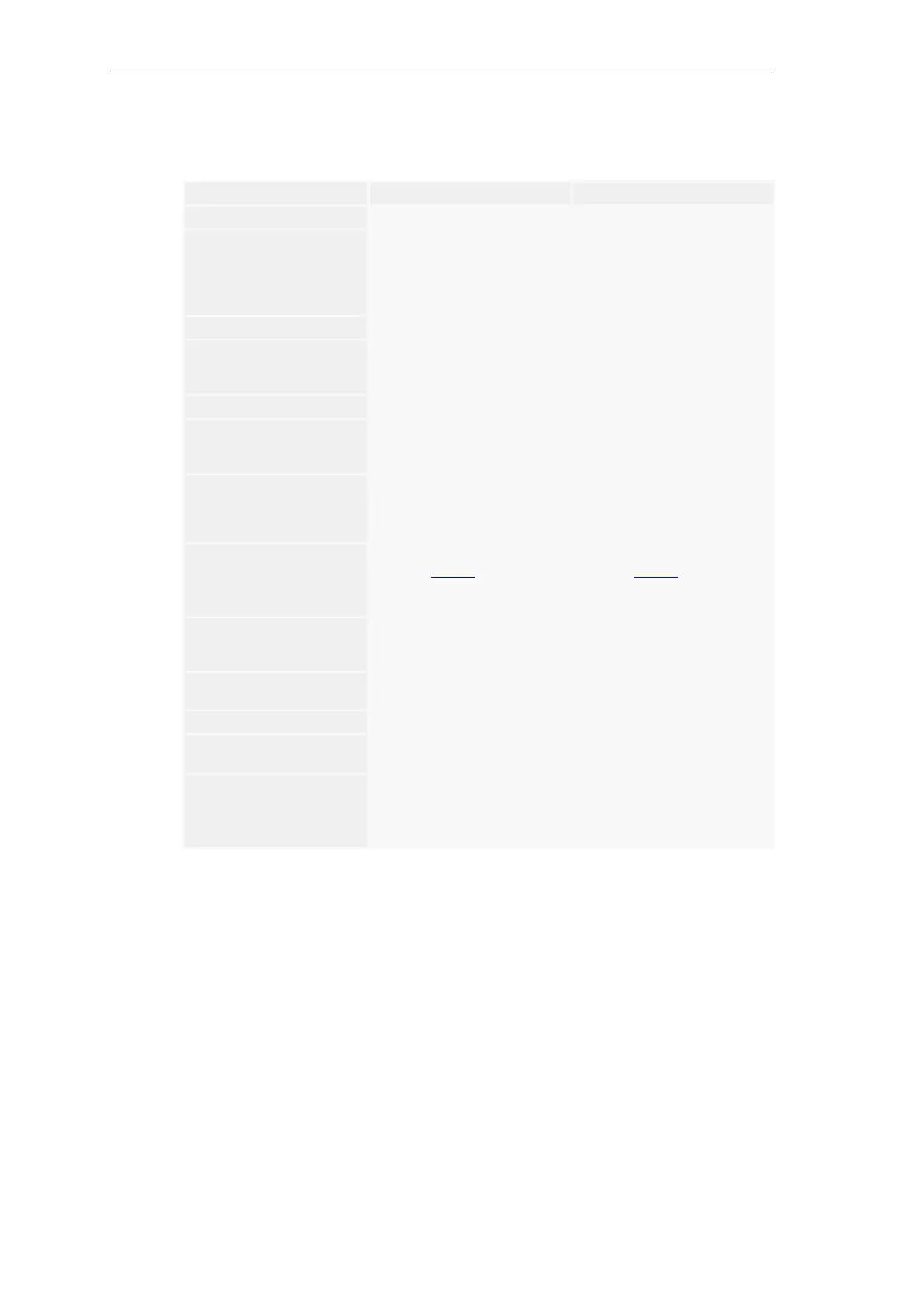

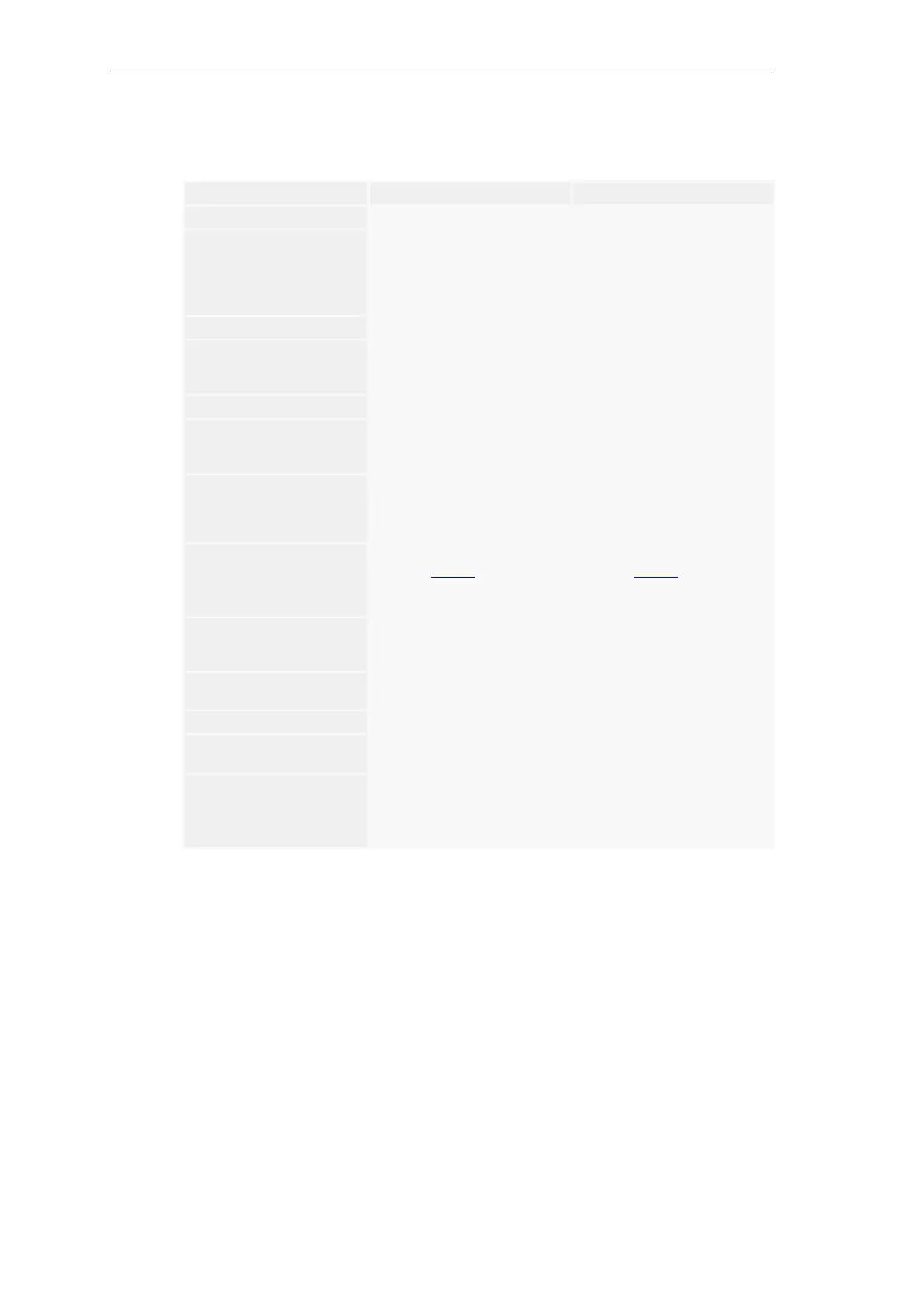

2.4.3 Differences with the Engineering Tools

SICAM TOOLBOX II SICAM WEB

License required ü –

Interfacing

• Directly via RS-232

• Remotely via Toolbox cable and

further SICAM RTUs automation

units

• Via Ethernet

• Directly via RS-232

• Via Ethernet

Addressing Via region, component Via IP address

Engineering mode Offline, subsequently transform

parameters and load into target

system

Online in the target system

Remote maintenance ü –

HW configuration I/O Modules must be configured in

the OPM II after configuring the

I/O Master Module

I/O Modules will be “learnt” auto-

matically after configuration of the

I/O Master Module and restart

Process-technical parameteri-

zation

• Images can be created for the

instancing of object types

• Bulk edit for the values of the

images possible

• Process signals are configured

individually per hardware I/O

• No automatic protocol parame-

terization

Application program Based on IEC 61131-3, with re-

strictions (memory)

• Function chart via CAEx plus

• Instruction list

Based on IEC 61131-3, with re-

strictions (memory)

• Instruction list

Test functions for Telecontrol

• Data flow test

• Topology test

• I/O test

I/O test (with restrictions)

Test of application program

• Online test

• Offline simulation

Online test (with restrictions)

Diagnosis ü With restrictions

Sum diagnosis information ü Via instruction list

Via SNMP traps

Extras Program Sicam_first_startup

(find all CP-8000/CP-802x devices

in a network and preset IP ad-

dresses)

Loading...

Loading...