NCK start-up

10.6 Parameterization of spindle data

CNC Part 1 (NCK, PLC, drive)

Commissioning Manual, 11/2006, 6FC5397-2AP10-2BA0

175

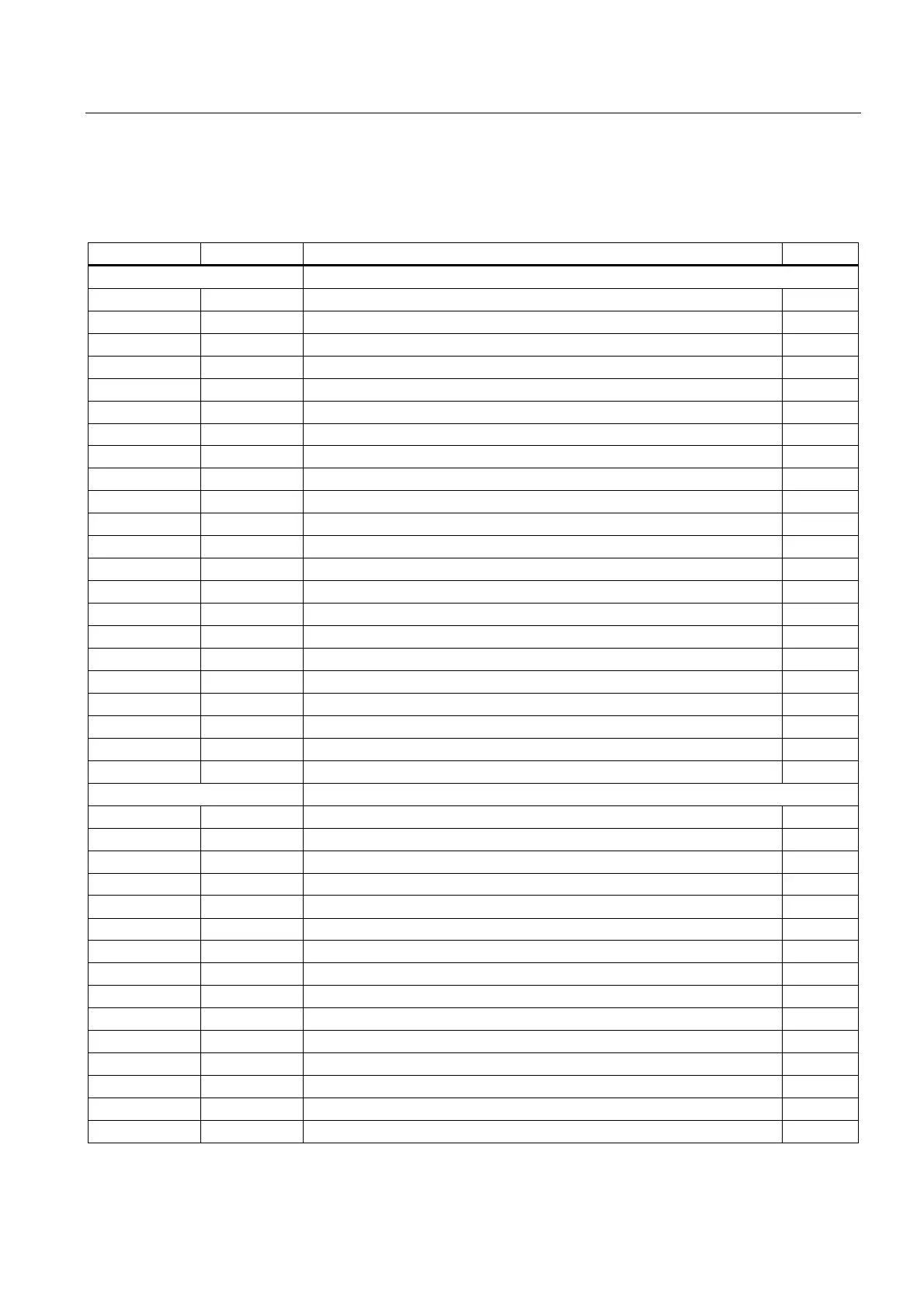

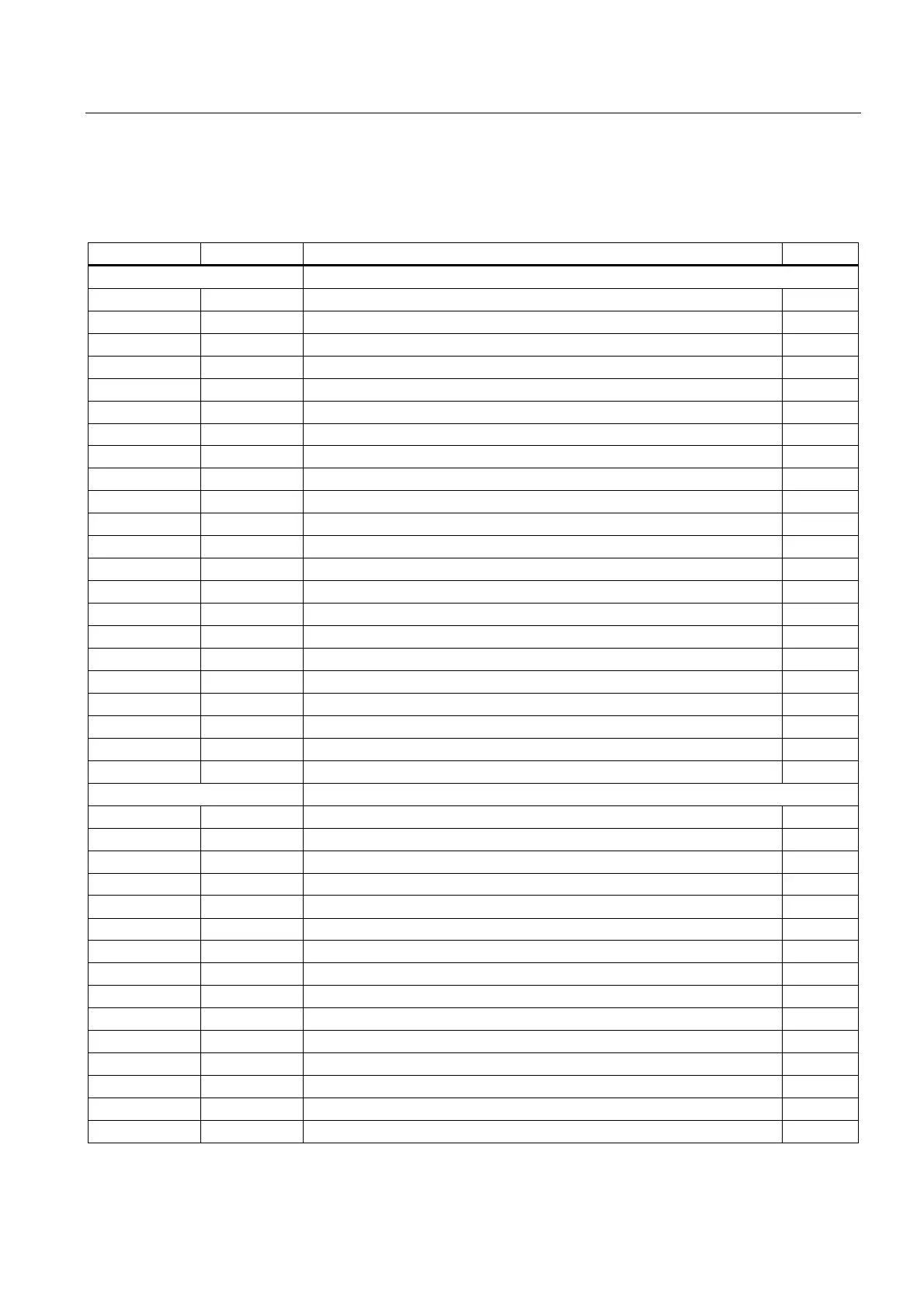

Interface signals

Table 10-35 Spindle: Interface signals

DB number Bit, byte Name Reference

Axis-specific Signals from PLC to axis/spindle

31, ... 0 Feed override V1

31, ... 1.7 Override active V1

31, ... 1.6 Position measuring system 2 A2

31, ... 1.5 Position measuring system 1 A2

31, ... 1.4 Followup mode A2

31, ... 1.3 Axis/spindle disable A2

31, ... 2.2 Spindle reset/delete distancetogo A2

31, ... 2.1 Servo enable A2

31, ... 3.6 Velocity/spindle speed limitation A3

31, ... 16.7 Delete S value

31, ... 16.5 Resynchronize spindle 2

31, ... 16.4 Resynchronize spindle 1

31, ... 16.3 Gear changed

31, ... 16.2-16.0 Actual gear stage A to C

31, ... 17.6 Invert M3/M4

31, ... 17.5 Resynchronize spindle during positioning 2

31, ... 17.4 Resynchronize spindle during positioning 1

31, ... 18.7 Direction of rotation setpoint left

31, ... 18.6 Direction of rotation setpoint right

31, ... 18.5 Oscillation speed

31, ... 18.4 Oscillation via PLC

31, ... 19.7 - 19.0 Spindle offset H - A V1

Axis-specific Signals from axis/spindle to PLC

31, ... 60.7 Position reached with exact stop fine B1

31, ... 60.6 Position reached with exact stop coarse B1

31, ... 60.5 Referenced/synchronized 2 R1

31, ... 60.4 Referenced/synchronized 1 R1

31, ... 60.3 Encoder limit frequency exceeded 2 A3

31, ... 60.2 Encoder limit frequency exceeded 1 A3

31, ... 60.0 Axis/no spindle

31, ... 61.7 Current controller active A2

31, ... 61.6 Speed control loop active A2

31, ... 61.5 Position controller active A2

31, ... 61.4 Axis/spindle stationary (n < nmin) A2

31, ... 82.3 Change gear

31, ... 82.2-82.0 Set gear stage AC

31, ... 83.7 Actual direction of rotation clockwise

31, ... 83.5 Spindle in setpoint range

Loading...

Loading...