Functions

2.36 Motor Starting Time Supervision (ANSI 48)

SIPROTEC, 7UM62, Manual

C53000-G1176-C149-7, Release date 03.2010

252

Therefore, if the starting current I actually measured is smaller (or larger) than the nominal starting current I

Start-

Curr

entered at address 6502 (parameter START. CURRENT), the actual tripping time t

TRIP

is lengthened (or

shortened) accordingly (see also Figure 2-114).

Definite-Time Overcurrent Tripping Characteristic (Locked Rotor Time)

If the motor starting time exceeds the maximum allowable blocked rotor time t

E

, tripping must be executed at

least with time t

E

when the rotor is blocked. The device can detect a blocked rotor condition via a binary input

(„>Rotor locked“) from an external rpm-counter. If the current in any of the phases exceeds the already

mentioned threshold I MOTOR START, a motor startup is assumed and in addition to the above inverse time

delay, a current-independent delay time (locked rotor time) is started. This happens every time the motor is

started and is a normal operating condition that is neither entered in the operational annunciations buffer, nor

output to a control centre, nor entered in a fault record.

The locked rotor delay time (LOCK ROTOR TIME) is ANDed with the binary input „>Rotor locked“. If the

binary input is still activated after the parameterized locked rotor time has expired, tripping is performed imme-

diately, regardless of whether the binary input was activated before or during the delay, or after the delay time

had elapsed.

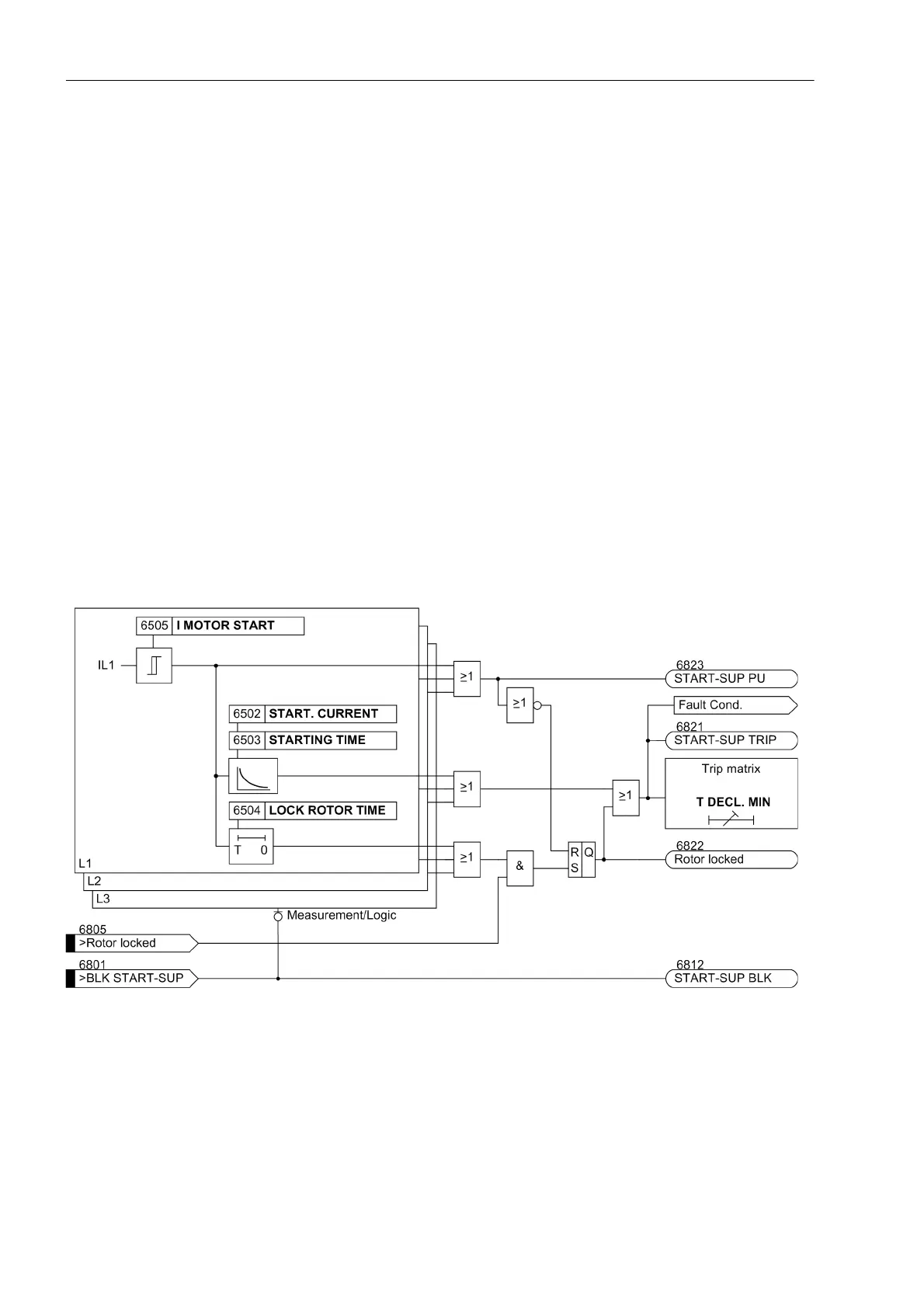

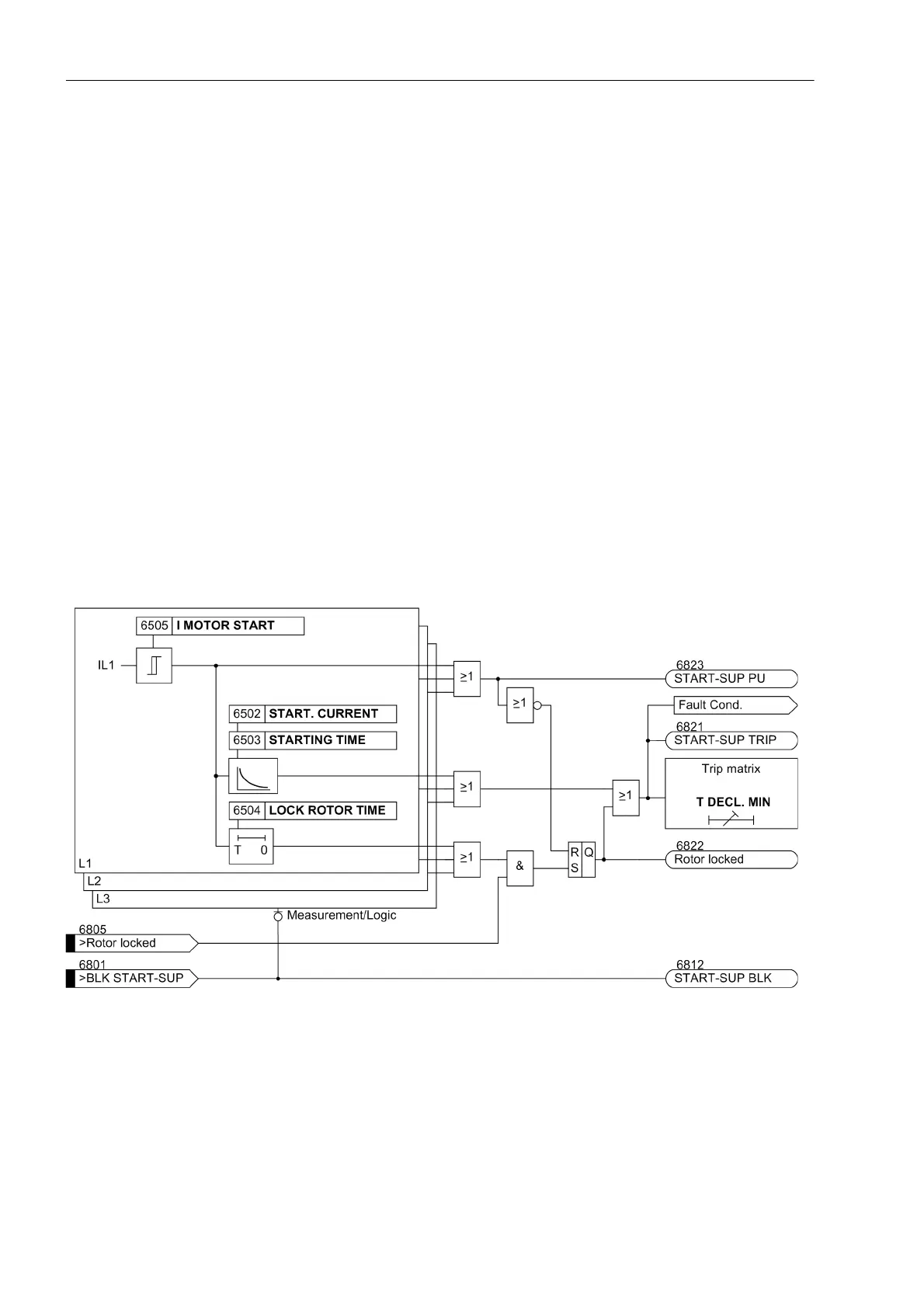

Logic

Motor startup monitoring may be switched on or off using a parameter. It may be blocked via binary input, i.e.

times and pickup indications are reset. The following figure shows the indication logic and fault administration.

A pickup does not result in a fault record. Fault recording is not started until a trip command has been issued.

Figure 2-115 Logic Diagram of the Motor Startup Time Monitoring

Loading...

Loading...