iCNC Perfromance

Manual 0-5401 APPENDIX B B-13

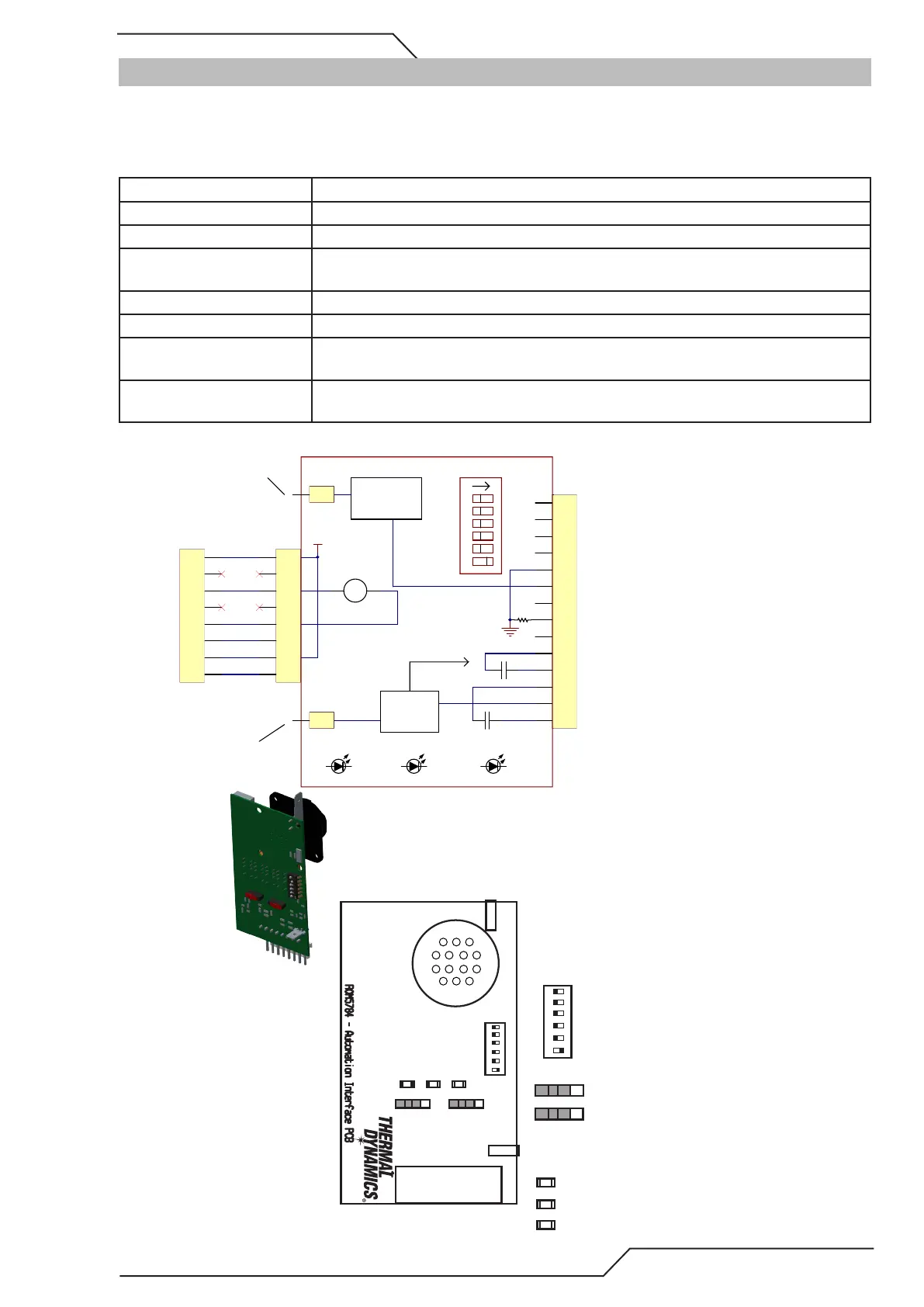

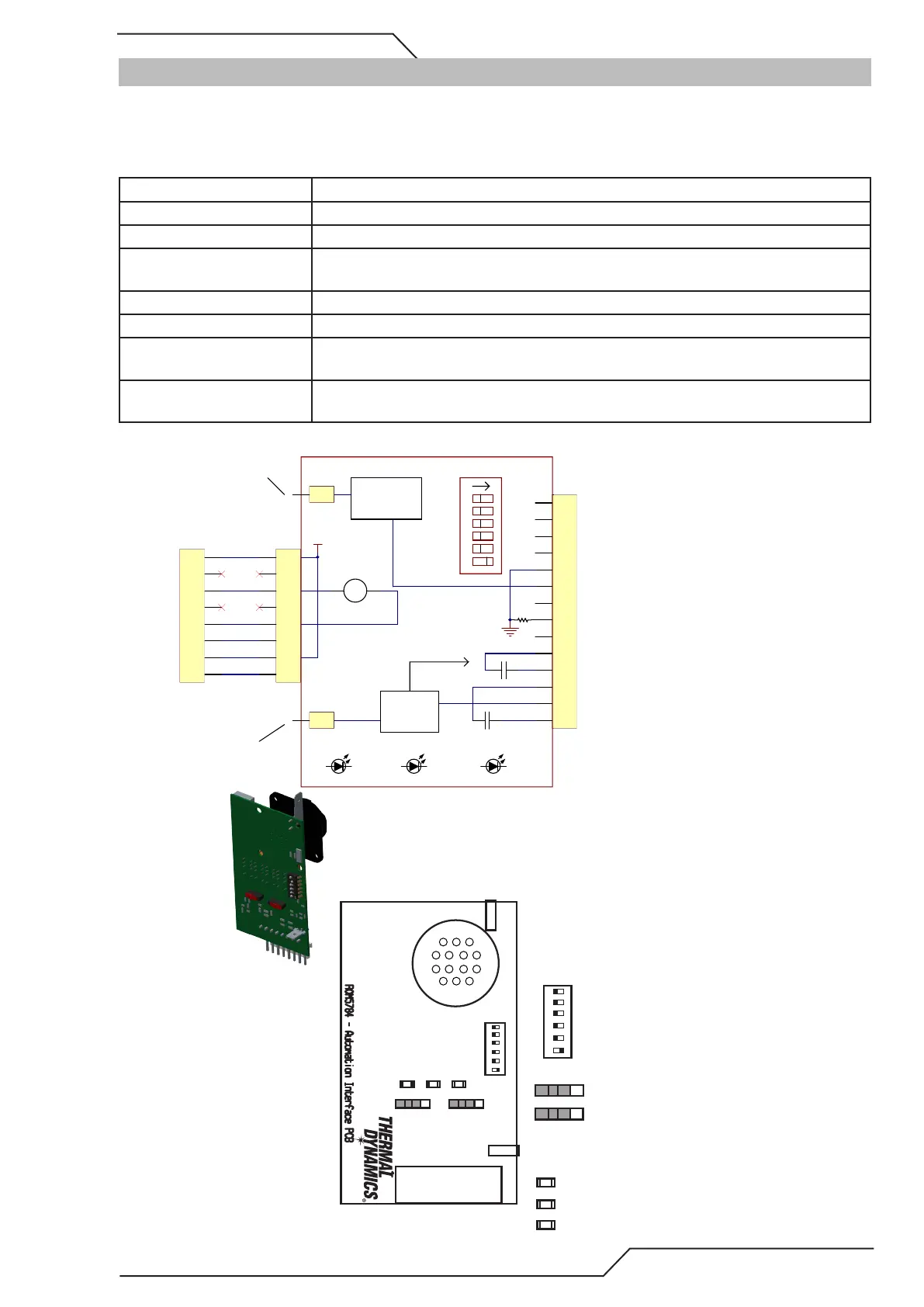

B.3 Thermal Dynamics A-Series Automation PCB

The Automation Interface PCB provides ohmic sensing (separate cable to ohmic clip), tip sensing (exposed consumables),

multiple arc voltage divisions and plasma I/O signals to the CNC.

Connections:

Contact rating 30VAC/VDC, 1 A max.

Minimum signals required Start / Stop and OK to Move.

Arc Voltage Selection (DIV1) Only 1 dip switch can be active at a time, measuring range 250V.

Arc Voltage Polarity Isolated from plasma power supply ground, change polarity by swapping wires on SIG

(J1-6) and COM (J1-5) Either pin can be grounded.

Arc Voltage Output Isolated from plasma power supply ground, both signal and com needs to be connected!

Ohmic Sensing With wire connected to J1-13 from shield cup.

Tip Sensing for Ign. Height If switch SW2 is ON Tip Sensing will trigger Plate Contact out when tip comes to contact

with Work. This only works with exposed parts.

Tip Sensing During Cutting If switch SW3 is ON tip sensing will trigger plate contact out when tip comes to contatc

with work while cutting. This only works with exposed parts.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

J1

1

2

3

4

5

6

7

8

*

J2

OK TO MOVE

GND

+12V

OK TO MOVE

1

-V_0UT1

1

TIP

1

2

3

4

5

6

7

8

P10

START / STOP

CONTACT

M-ARC

START

123456

DIV1

CONTACT

Ohmic

sensing

circuits

To TIP1

MAIN PCB

(PCB1)

Start / Stop (COM), dry contact to #4 will re the arc

Start / Stop, dry contact to #3 will re the arc

Divided Arc voltage out (COM)

Divided Arc voltage out (SIG)

COMMON

Plate contact (COM)

Plate contact (OUT)

OK to Move (COM)

OK to Move (OUT)

Ohmic input from shield cup

To -V OUT 1

Main PCB

( PCB1)

Voltage

Divider

Signals

1

I 0 I

0

2 3 4 5 6

ON

1 2 3 4 5 6

ON

I 0

I

0

Div 1

Div 1

Divider ratio:

1 ON rest OFF 16.67:1 (SC11)

2 ON rest OFF 20:1 (ESAB)

3 ON rest OFF 30:1

4 ON rest OFF 40:1(INOVA)

5 ON rest OFF 50:1(IHT, SC3000, Hypertherm)

6 ON rest OFF 80:1(iHC, iCNC Performance)

Switches:

SW2 = Tip sensing ON

SW3 = Tip sensing during cutting ON

LEDs:

Contact, red: Plate contact active when illuminated

Connector -V0_1:

Wire to plasma MAIN PCB (PCB1)

Connector TIP:

Wire to plasma main board

Connector J2:

Cable to J10 on plasma MAIN PCB (PCB1)

M-Arc, green: Main arc output ON when illuminated

Start, yellow: Plasma Start input ON when illuminated

SW2

SW3

CONTACT M-ARC START

SW3SW2

CONTACT

M-ARC

START

1 3

1412

J1

TIP

-V_OUT1

J2

Loading...

Loading...